Tube Ref

No.

Description Where Used Part No.

Extreme Grease Length of driveshaft 8M0071842

• Lubricate the splines on the propeller shaft.

• Drain and replace the gearcase lubricant.

• Inspect all belts, pulleys, and idler pulleys for deterioration.

•

Check the fuel pressure.

1.

• Check the control cable adjustments.

• Inspect the battery.

• Check the corrosion control anodes.

• Check the tightness of all fasteners.

• Check the power trim fluid.

• Use Quicksilver products to remove engine deposits. See your dealer for

an explanation of which products to use.

EVERY 100 HOURS OR ONCE A YEAR, WHICHEVER OCCURS FIRST

• Tighten the fasteners that secure the outboard to the boat transom to the

specified torque.

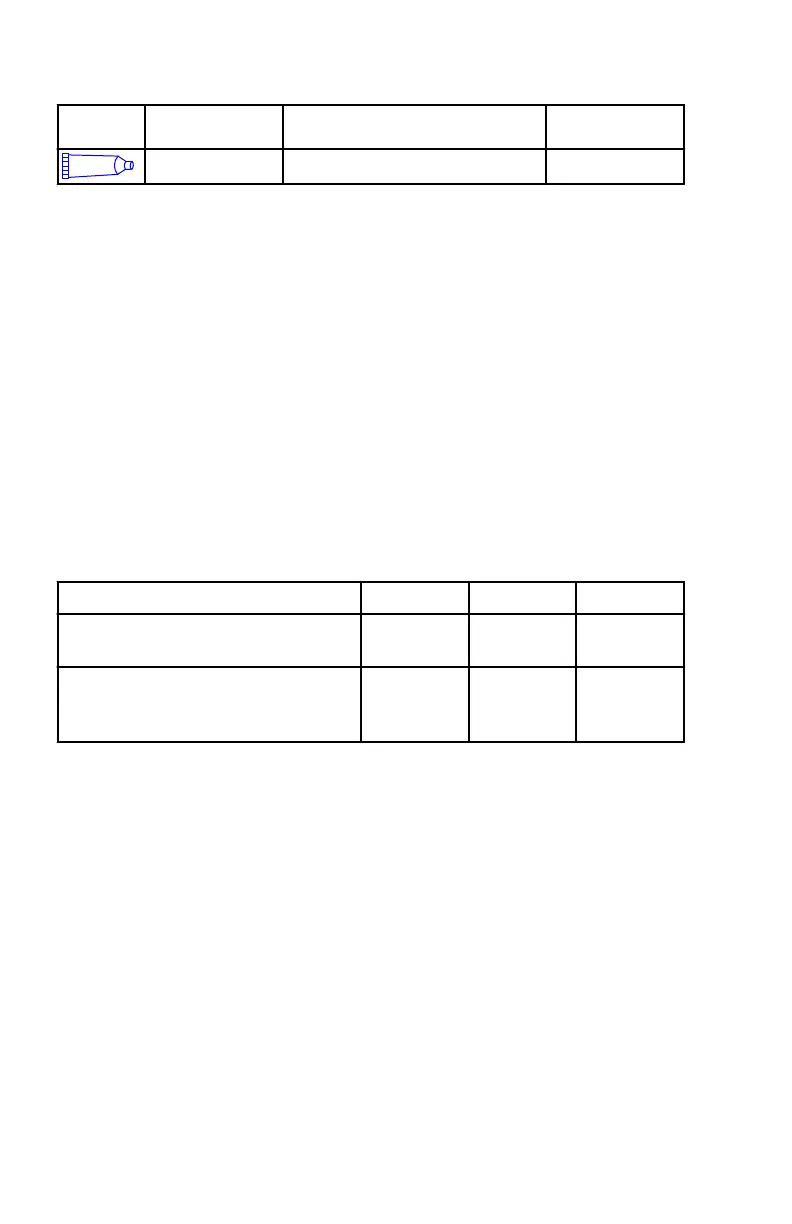

1.

Description

Nm lb‑in. lb‑ft

Outboard mounting locknuts and

bolts – standard boat transom

75 – 55

Outboard mounting locknuts and

bolts – metal lift plates and setback

brackets

122 – 90

• Replace the water pump impeller (more often if overheating occurs or

reduced water pressure is noted).

1.

• Replace the spark plugs after the first 100 hours or first year. After that,

inspect the spark plugs every 100 hours or once yearly. Replace the

spark plugs as needed.

• Replace the water‑separating fuel filter.

• Replace the in‑line oil filter after the first 100 hours of operation.

• Use Quickleen in the fuel.

• Verify that the cowl seals are intact and not damaged.

• Check that the internal cowl sound reduction foam (if equipped) is intact

and not deteriorating.

• Ensure that the intake silencer (if equipped) is in place.

• Ensure that the idle relief muffler (if equipped) is in place.

• Check for loose hose clamps and rubber boots (if equipped) on the air

intake assembly.

MAINTENANCE

76 eng

Loading...

Loading...