SECTION 2 - GENERAL INSTALLATION INFORMATION

2-8

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

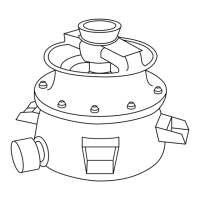

Table 2-3 MP1000 Clearance Dimensions (refer to Figure 2-4)

Callout Description

Standard

mm (in.)

Short Head

mm (in.)

A Main frame flange

1950

(6' 4-3/4")

1950

(6' 4-3/4")

B Main frame flange

2000

(6' 6-3/4")

2000

(6' 6-3/4")

C Main frame flange

1950

(6' 4-3/4")

1950

(6' 4-3/4")

D Main frame hub diameter

975

(3' 2-3/8")

975

(3' 2-3/8")

E To bottom of main frame hub

310

(1' 0-3/16")

310

(1' 0-3/16")

F To bottom of oil piping

670

(2' 2-3/8")

670

(2' 2-3/8")

G To top of turning brackets

3660

(12' 0-1/8")

3660

(12' 0-1/8")

H Adjustment ring maximum diameter

5360

(17' 7")

5360

(17' 7")

J Clearance required for removing countershaft assembly

4320

(14' 2-1/16")

4320

(14' 2-1/16")

K To end of countershaft

2855

(9' 4-3/8")

2855

(9' 4-3/8")

L Maximum height to top of feed hopper

3926

(12' 10-9/16")

3993

(13' 1-3/16")

M Inside diameter of feed hopper

2530

(8' 3-5/8")

2490

(8' 2-1/16")

N To top of feed plate

3026

(9' 11-1/8")

2935

(9' 7-9/16")

O Overall height of bowl assembly

2186

(7' 2-1/16")

2180

(7' 1-13/16")

P Adjustment cap maximum diameter

3550

(11' 7-3/4")

3550

(11' 7-3/4")

Q Clearance required for removing bowl assembly

5896

(19' 4-1/8")

5890

(19' 3-7/8")

R Overall height of head assembly

2323

(7' 7-1/2")

2127

(6' 11-3/4")

S Head or mantle maximum diameter

2392

(7' 10-3/16")

2369

(7' 9-1/4")

T Clearance required for removing head assembly

6033

(19' 9-1/2")

5837

(19' 1-13/16")

U Tramp release side to side

4610

(15' 1-1/2")

4610

(15' 1-1/2")

V Additional upward travel due to clearing stroke

150

(5-15/16")

150

(5-15/16")

Loading...

Loading...