MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

5-1

Eccentric Assembly

S

ECTION

5

5.1 Description

This section covers the eccentric assembly

including the eccentric, eccentric bushing, gear and

counterweight. The eccentric which has an offset

bore provides the means whereby the head follows

an eccentric path during each cycle or rotation. An

eccentric bushing locked into the eccentric bore

provides the bearing surface for the main shaft.

Note that although not part of the eccentric

assembly, an eccentric bushing Resistance

Temperature Detector (RTD) is mounted to the

mainframe just beneath the lower edge of the

eccentric bushing. This RTD monitors the

temperature of the oil exiting the lower end of the

eccentric bushing.

A large bevel gear bolted to the bottom of the

eccentric is driven by the pinion on the

countershaft. The eccentric rotates around the

stationary main shaft. The entire assembly is

supported by a set of thrust bearings; the upper

thrust bearing is bolted to the bottom of the

eccentric and the stationary lower thrust bearing is

bolted to the main frame. Backlash and root

clearance between gear and pinion teeth are

maintained in this assembly by the addition or

subtraction of shims inserted beneath the lower

thrust bearing.

The counterweight installed on the eccentric has a

light and heavy side and is positioned so as to

reduce the unbalanced forces created by the motion

of the head assembly. Protecting the MP1000

counterweight from falling discharging material is

the counterweight guard bolted to the

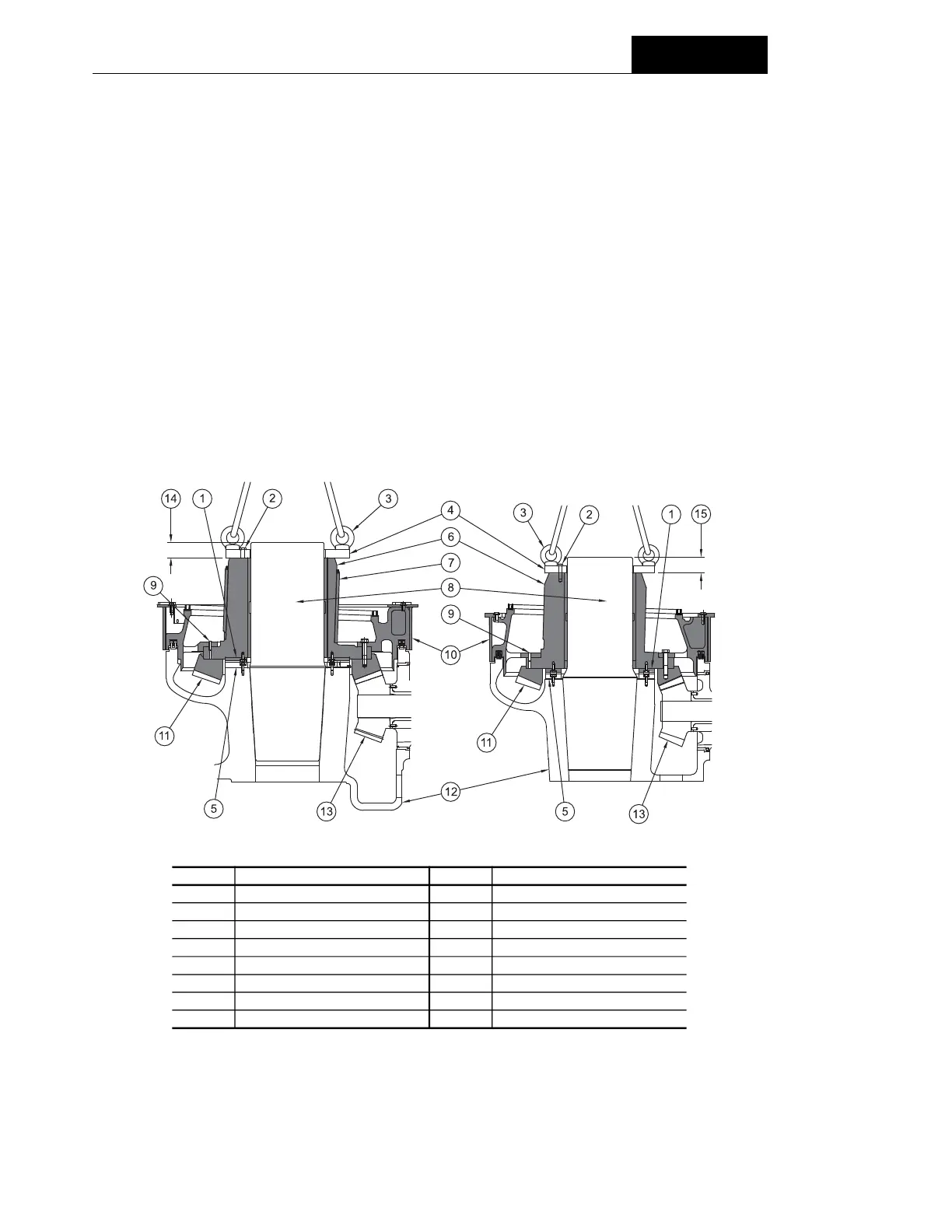

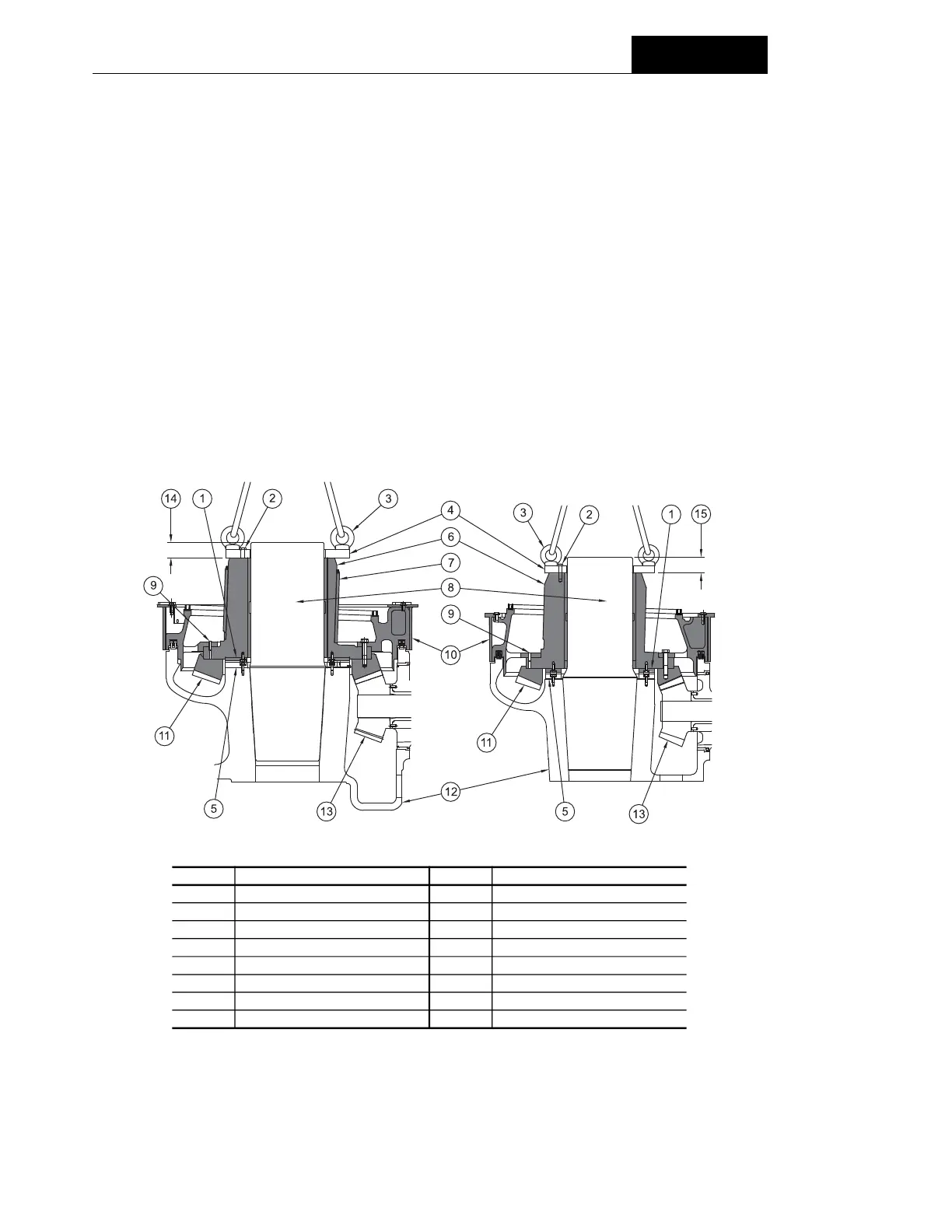

counterweight. Refer to Figure 5-1.

Protecting the MP800 counterweight is a

counterweight guard that is bolted to the

counterweight. Refer to Figure 5-1.

Figure 5-1 Eccentric Assembly Installation

Callout Description Callout Description

1 Upper thrust bearing 9 Couterweight location dowel

2 M30 Capscrews 10 Counterweight guard

3 Ring bolts 11 Gear

4 Lifting ring 12 Main frame

5 Lower thrust bearing 13 Pinion

6 Eccentric 14 135 mm (5.31")

7 Eccentric Sleeve 15 140 mm (5.51")

8 Main shaft

MP1000

MP800

Loading...

Loading...