Slurry Pump

WH16AA1LA00EN_01E.DOC JAN 04-W08

Care and maintenance

2/3

9.4.2 Lubrication interval

The bearings may be re-greased with any lithium-based grease that conforms to the

specification detailed in Table 9.4.1-1.

The lubrication interval depends upon the shaft speed and the bearing operating

temperature, as shown in Table 9.4.2-1.

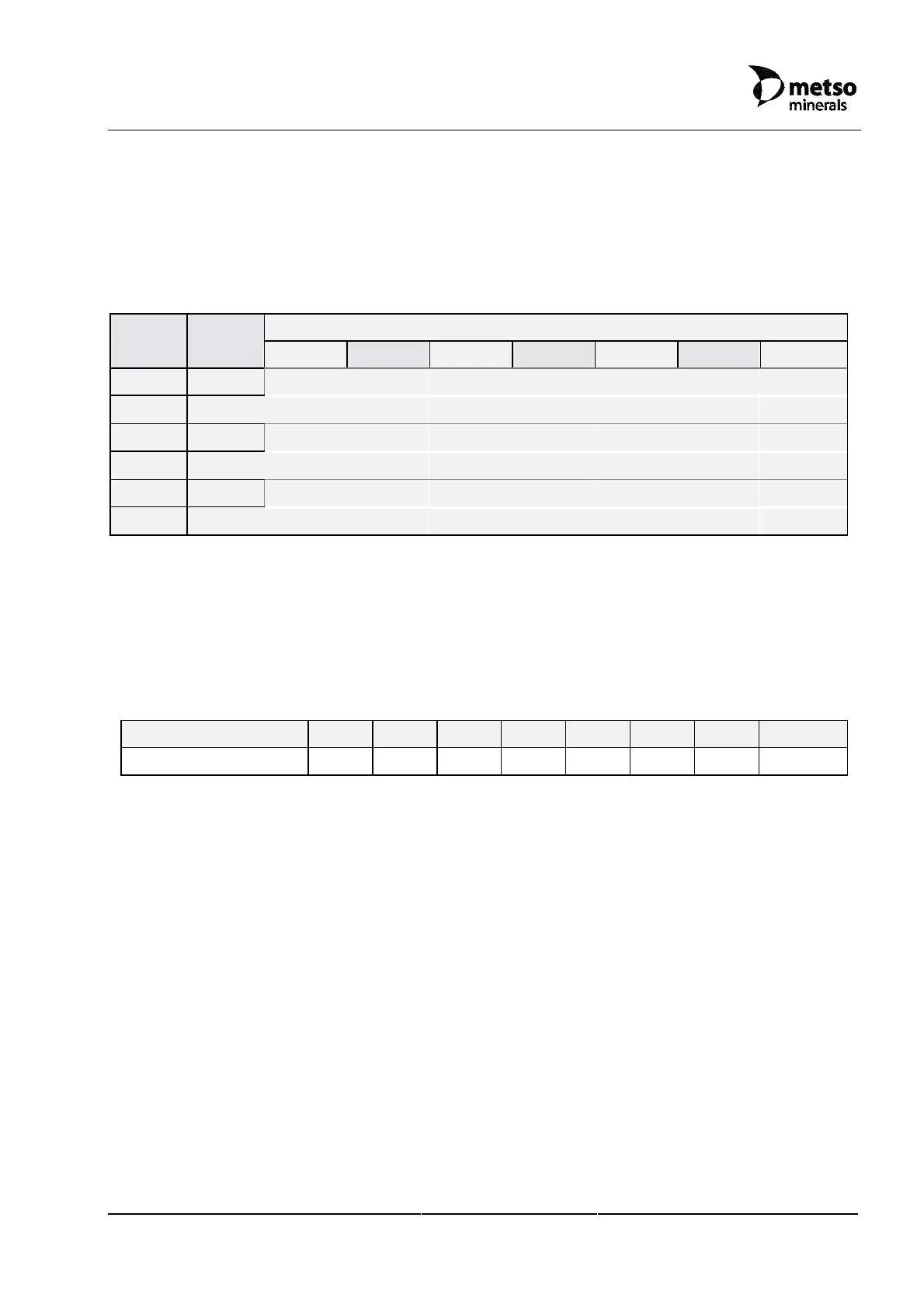

Frame Grease Pump speed (rpm)

Size (g) 500 800 1000 1500 2000 2500 3000

FR250

20 2275 1500 1000 650 500 350 250

FR300

25 1600 1300 900 600 400 300 200

FR400

35 1250 1000 750 500 350 - -

FR500

50 1250 900 550 350 - - -

FR600

70 1250 800 350 200 - - -

FR750

90 900 550 200 - - - -

Table 9.4.2-1 Recommended lubrication interval for bearings @ 70°C (hours)

The pump should initially be re-greased after 250 running hours or the recommended

interval (whichever is less), unless stored for longer than 12 months before start-up, in

which case the long-term storage instructions should be followed (See section 1.2).

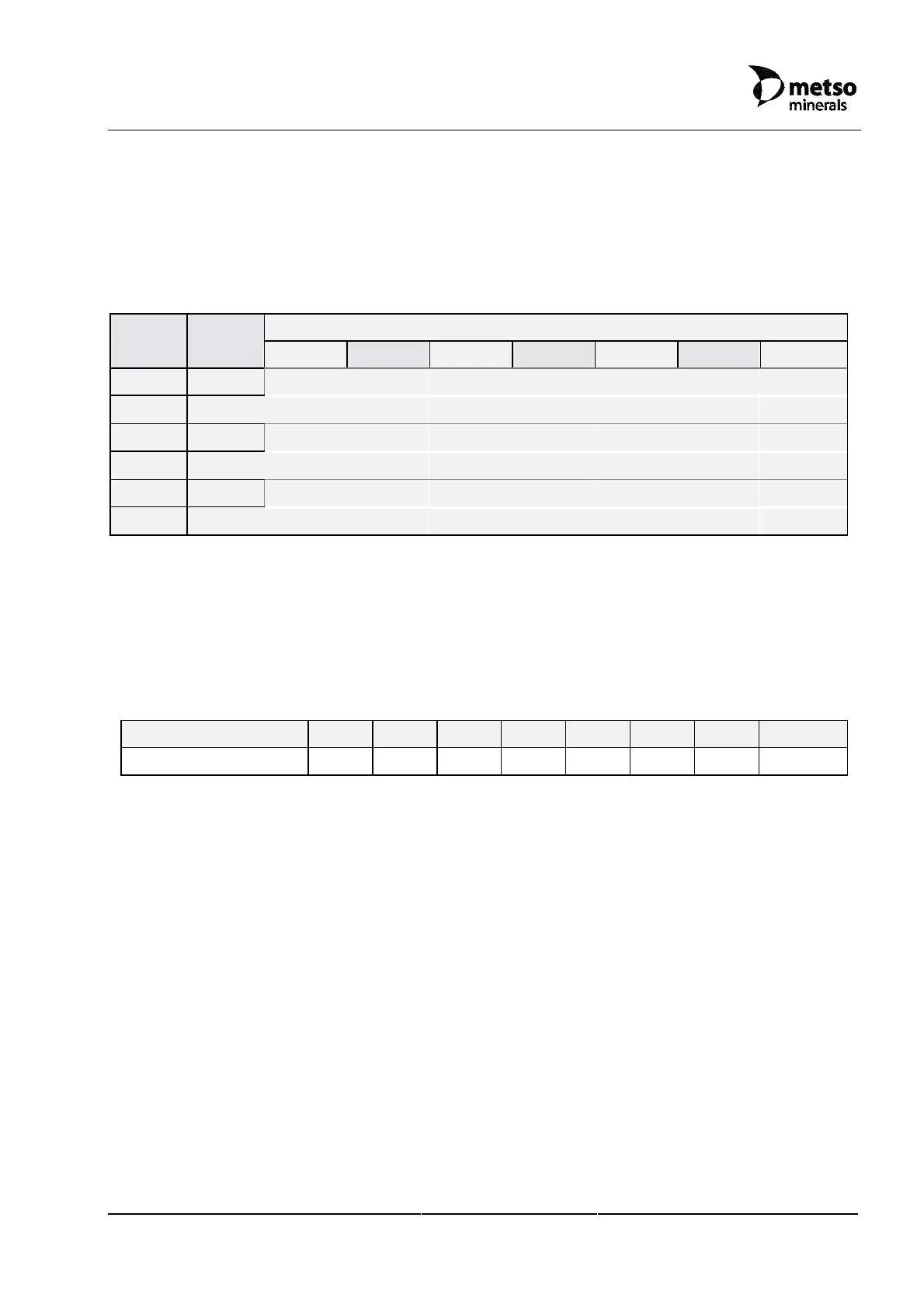

Multiply above lubrication intervals by the factors given below if the normal bearing

operating temperature (measured on the rim of the bearing end cover) differs from 70 °C.

Temperature (°C) 50 60 70 80 90 100 110 120

Multiplier 2.5 1.6 1.0 0.65 0.40 0.25 0.15 0.10

While the bearings and specified grease have a maximum operating temperature of

120°C, it is recommended that temperatures above 100 °C be avoided. However,

transient temperatures between 100 °C and 120 °C are acceptable immediately following

re-greasing.

Loading...

Loading...