Cooling

System

Frost

Anti-freeze can remain in the cooling system for two years provided

that

the

precautions

specific gravity of the coolant is checked periodically

and

anti-freeze added as

necessary. The specific gravity check should be carried out by an

author

ized

Distributor or Dealer.

Only top up when the cooling system is at its normal running temperature in

order to avoid losing anti-freeze due to expansion.

After the second winter the system should be drained

and

flushed. Refer to the

instructions given for draining the cooling system, then clean out the system

thoroughly by flushing water through the radiator passages using a hose inserted

in the radiator filler orifice.

Before adding the recommended anti-freeze make sure

that

the cooling system

is watertight; examine all joints

and

renew any defective hose. '

We recommend owners to use UNIPART Frostbeat or Bluecol Anti-freeze to

protect the cooling system during frosty weather

and

reduce' corrosion to the

minimum. We also approve the use of anti-freeze which conforms to specification

B.S.3151 or B.S.3152.

The correct quantities of anti-freeze for different degrees of frost protection are:

.-

Anti

Commences

freeze to free ze Frozen solid Amount

of

anti-freeze

%

0c.

OF.

0c.

of .

Pts.

US

. Pts. Litres

25

-13

9

-26

•

-15

It

2

·85

33t

- 19

-2

-36

-33

2

21

1·14

50

- 36 - 33

-48

- 53

3

31

1·17

After the second winter the system should be drained

and

flushed. Refer to the

instructions given for draining the cooling system, then clean out the system

thoroughly by flushing water through the radiator passages using a hose inserted

in the radiator filler orifice.

Before adding the recommended anti-freeze make sure

that

the cooling system

is watertight; examine all joints

and

renew any defective hose. '

We recommend owners to use UNIPART Frostbeat or Bluecol Anti-freeze to

protect the cooling system during frosty weather

and

reduce' corrosion to the

minimum. We also app rove the use of anti-freeze which conforms to specification

n Cl "' ...

r1

n C" ..., ...

r"

WHEELS

AND

TYRES

Jacking

up

The

jack

is designed to lift one side of the car at a time. Apply the

hand

brake,

Fig. 1 and block the wheels on the opposite side of

that

being jacked, use a wood block

jammed tight against the tyre tread.

Remove the plug from the jacking socket

located

on the door sill panel and .

insert the lifting arm of the jack into the socket.

Make

certain that the jack lifting

arm is pushed fully into the socket and that the base of the jack is on firm ground.

The jack should lean slightly outwards at the top to allow for the radial move-

ment of the car as it is raised.

WAR

NIN

G. Do not work beneath the vehicle with the lifting jack as the sole means

of support. Place suitable supp orts under the front side members or rear axle to

give adequate support and safety while working.

Jack

If

the jack is neglected it may be difficult to use in a roadside emergency. Examine

maintenance

it occasionally, clean off accumulated dust, and lightly oil the thread to prevent

the formation of rust.

WHEELS

Preventive

Owners are recommended to check wheel nuts on pressed type wheels for

maintenance

tightness each week. Take care

not

to overtighten (torque wrench setting 44 to

46 lb. ft. (6'08 to 6·36 kg. m.).

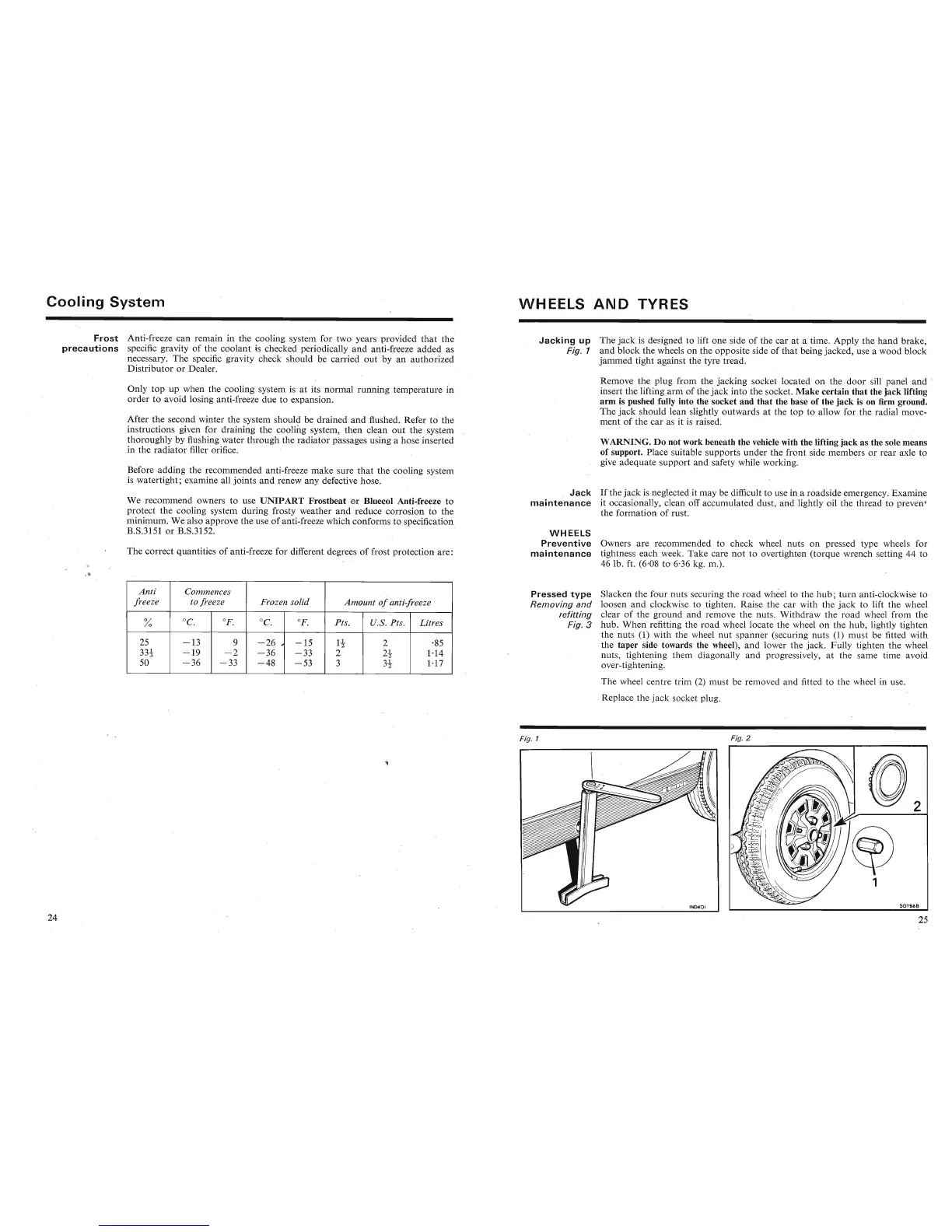

Pressed

type

Slacken the four nut s securing the road wheel to the hub ; turn anti-clockwise to

Removing

and

loosen and clockwise to tighten. Raise the car with the jack to lift the wheel

refitting

clear of the gro und and remove the nuts. Withd raw the road wheel f

rom

the

Fig . 3 hub. When refitting the

road

wheel locate the wheel on the hub , lightly tighten

the nuts (1) with the wheel nut spanner (securing nuts

(1) must be fitted with

the taper side towards the wheel), and lower the jack. Fully tighten the wheel

nuts, tightening them diagonally and progressively, at the same time avoid

over-tightening.

The wheel centre trim (2) must be removed and fitted to the wheel in use.

.Replace the

jack

socket plug.

Fig. 2

WARNING. Do not work beneath the vehicle with the lifting jack as the sole means

of support. Place suitable supp orts under the fron t side members or rear axle to

give adequa te support and safety while working.

Jack

If

the jack is neglected it may be difficult to use in a roadside emergency . Examine

maintenance

it occasionally, clean off accumulated dust, and lightly oil the thread to prevent

the formation of rust.

Loading...

Loading...