the distributor cover.

011

removing the distributor cover the position of the

metal electrode on the end of the distributor rotating arm can be seen, and

its position relat ve to this stud noted. That the pistons are exactly

at

the

top of their travel can he ascertained by removing the rectangular plate vn

the clutch housing (just in front of the gear lever), when a rn;~rk will be found

on the face of the flywheel, hearing the numbers

114.

This mark should be

exactly in the centre of the opening in the clutch housing.

Having made sure that the pistons and camshaft are in their correct

positions, the head may be lowered into position on to the cylinder block.

The two holes in

the flexible coupling should now coincide with those on the

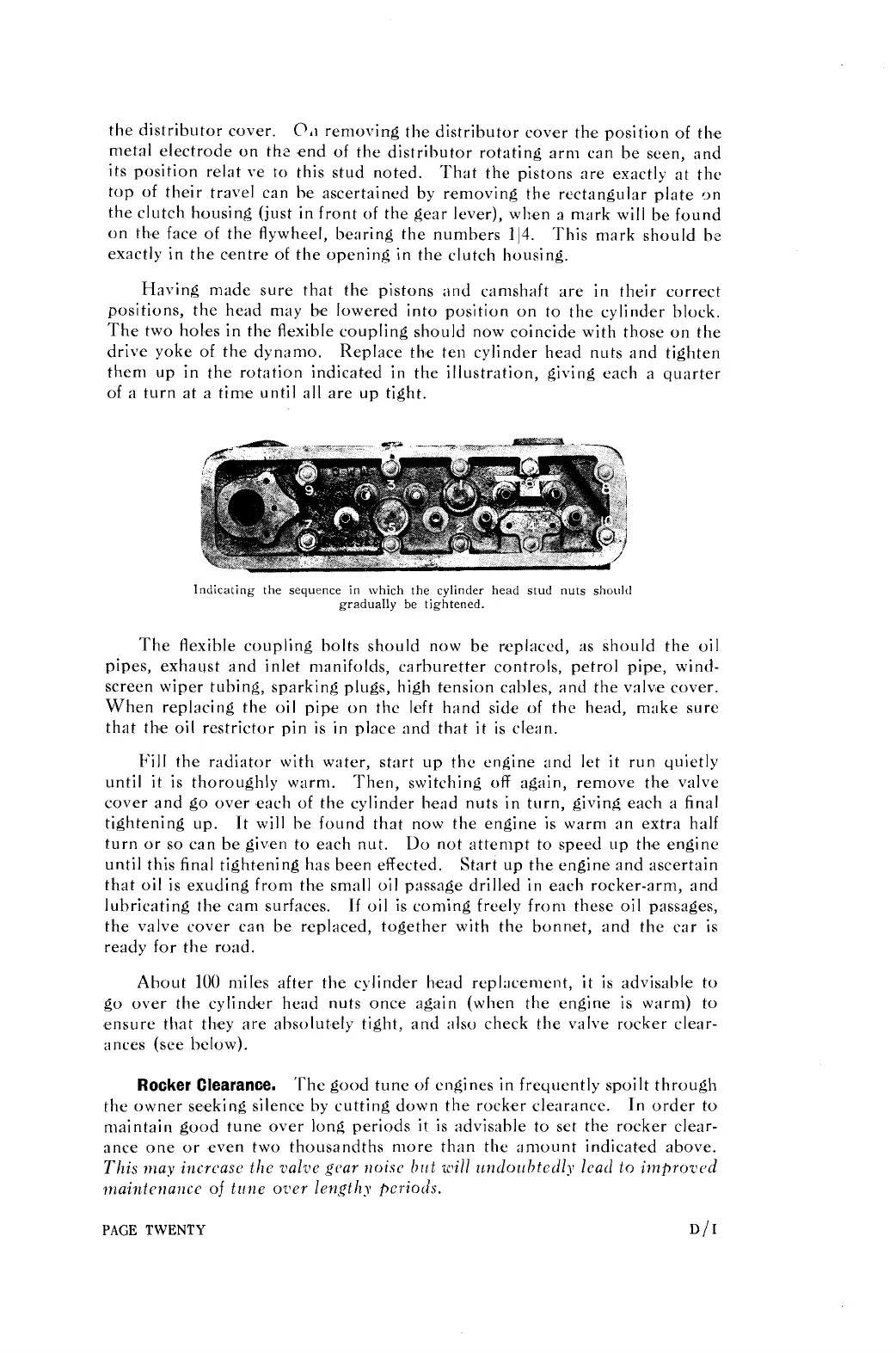

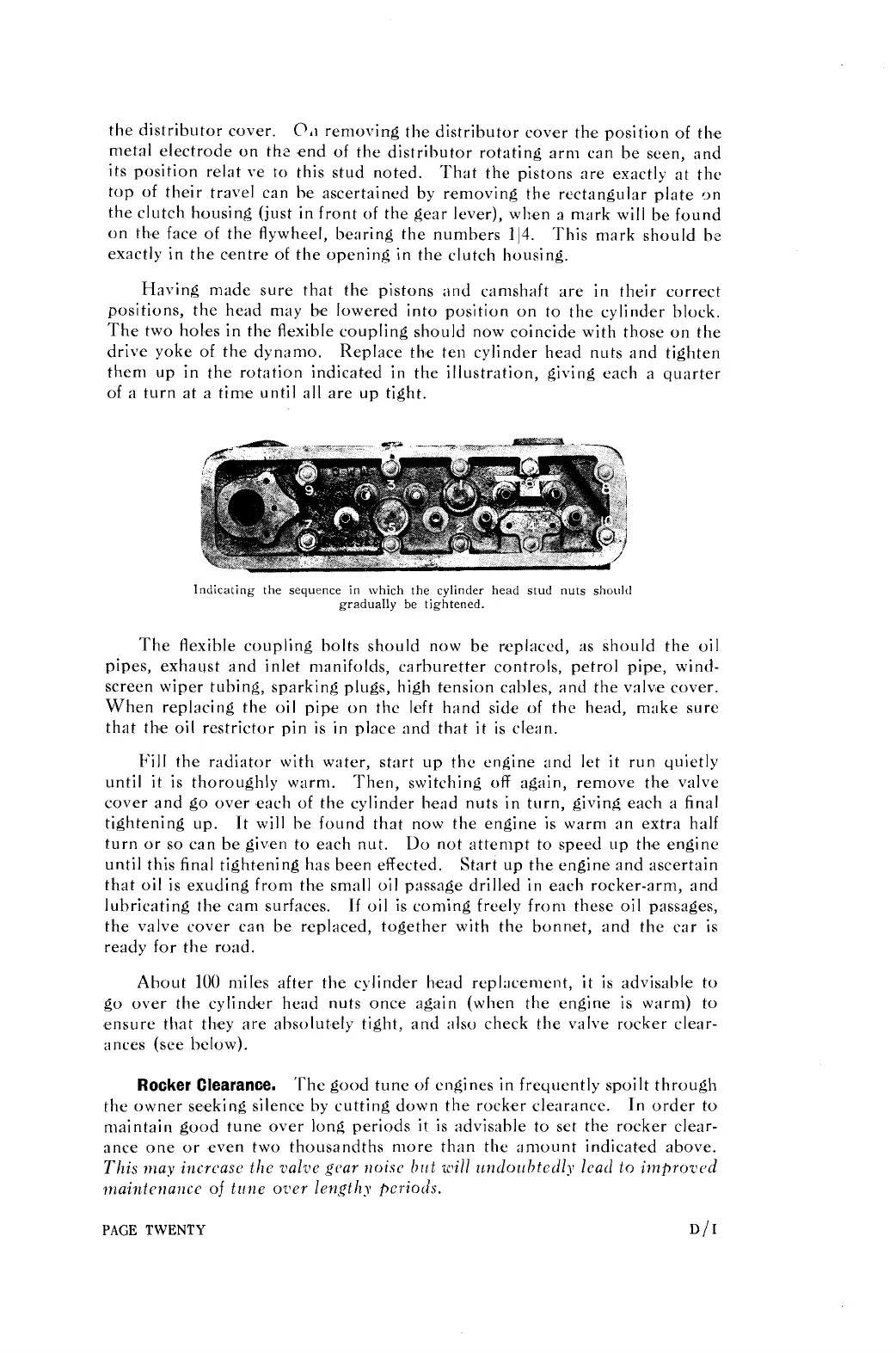

drive yoke of the dynamo. Replace the ten cylinder head nuts and tighten

them up in the rotation indicated

in

the illustration, giving each a quarter

of

a

turn at a time until all are up tight.

Indicating the sequence in which the cylinder head stud

nuts

shoultl

gradually be tightened.

The flexible coupling bolts should now be

replaced,

as should the oil

pipes, exhaust and inlet manifolds, carburetter controls, petrol pipe, wind-

screen wiper tubing, sparking plugs, high tension cables, and the valve cover.

When replacing the oil pipe on the left hand side of the head, make sure

that

th,e oil restrictor pin is in place and that it is cle:~n.

Fill

the radiator with water, start up the engine and let it run quietly

until it is thoroughly warm.

Then, switching off again, remove the valve

cover and

go over each of the cylinder head nuts in turn, giving each a final

tightening up. It will be found that now the engine is warm an extra half

turn or so can be given to each nut. Do not attempt to speed

LIP

th'e engine

until this final tightening has been effected. Start up the engine and ascertain

that oil is exuding from the small oil passage drilled

in

each rocker-arm, and

lubricating the cam surfaces.

If

oil is coming freely from these oil passages,

the valve cover can be replaced, together with the bonnet, and the car is

ready for the road.

About

100

miles after the wlinder head repl:~cement, it is advisable to

go over the cylinder head nuts once again (when the engine is warm) to

ensure that they are absolutely tight, and nlso check the valve rocker clear-

ances (see below).

Rocker Clearance.

'The good tune

of

engines in frequently spoilt through

the owner seeking silence hy cutting down the rocker clearance.

In order to

maintain good tune over long periods it is advisable to set the rocker clear-

ance one or even two thousandths more than the amount indicated above.

This may incrcasc the calile goar ~loisc

hilt

wd1

z~ndozlhtedly lead to imfirovcd

maintenallcc of tune ocer lengthy ficriotis.

PAGE

TWENTY

D/I

Loading...

Loading...