A

large percentage of the

carburetters

returned to the Works for

correction have had the jet removed and replaced without being correctly

centred. On no account should the jet he tampered with.

It is quite an easy matter to bend the needle

if

the piston is

:~t

any tinie

removed, in which case

it

will hind on the jet and cause the piston to stick.

To ascertain

if

the needle is bent-providing the jet is not out of centre-

remove

it

from the piston, refit the suction chamber on to the hody of the

carhuretter and see

if

the piston falls freely. If the needle is bent the onls

satisfactory remedy is

to

replace

it

by

a

new one.

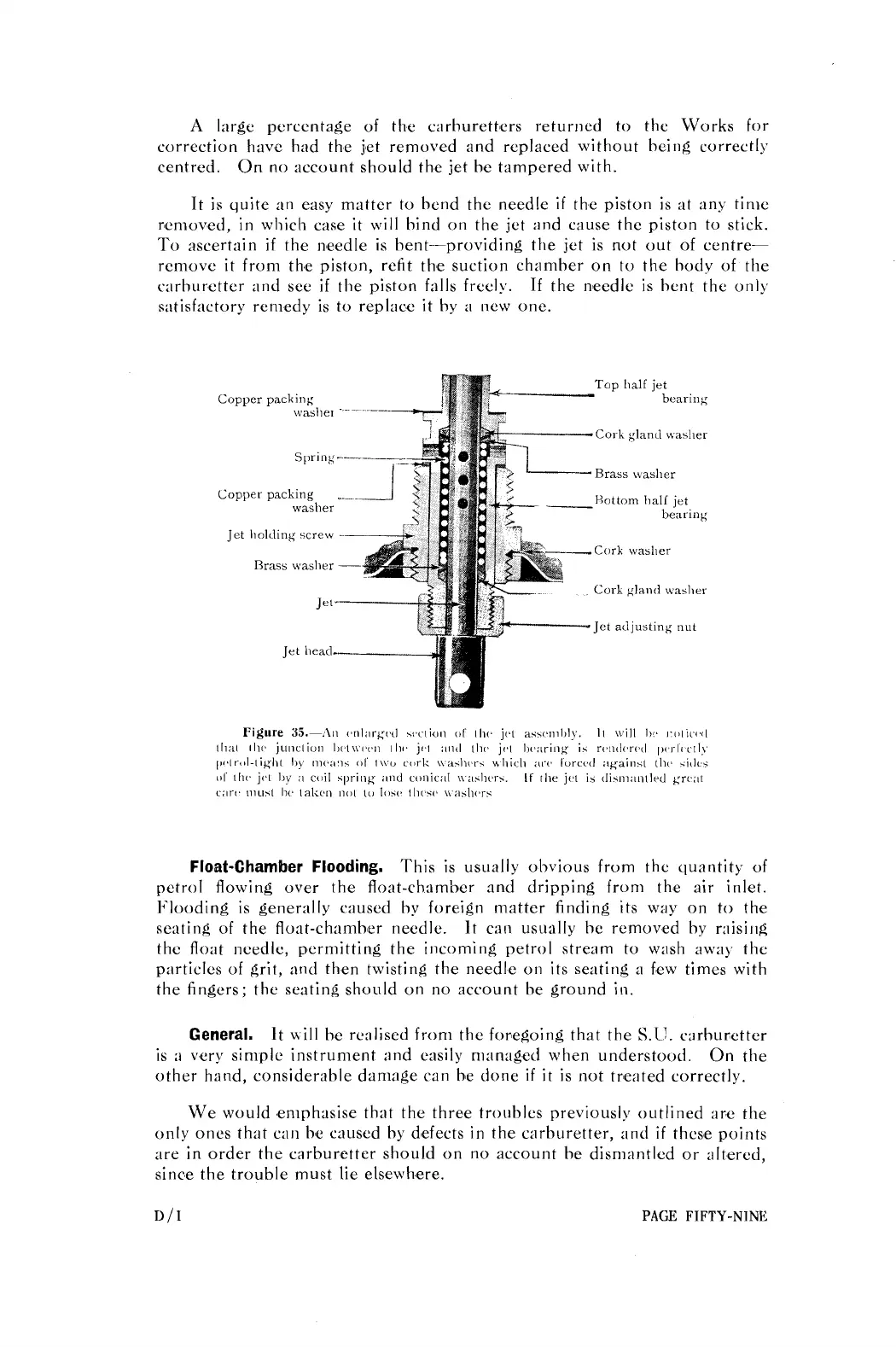

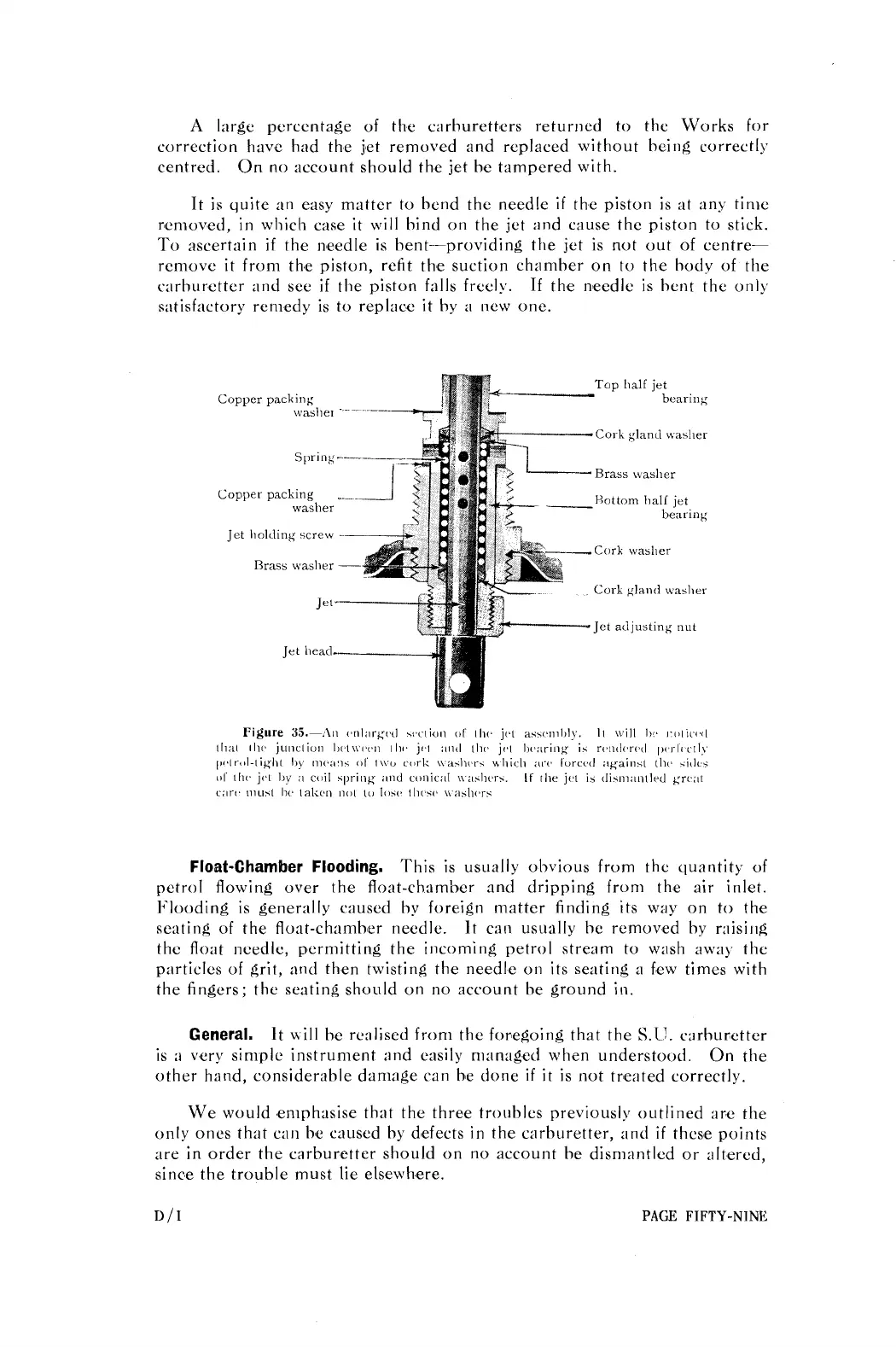

Coaver aacliin~

-

packing

washer

3Iding screw

Top half jet

bearing

Cork gland \vasher

Brass washer

Hottom hall jet

bearing

-,Cork washer

Cork gland was11t.r

Jet adjusting nut

Brass

washer

--

-g

Jet head.-

d

Float-Chamber Flooding.

This is usually obvious from the cluantity of

petrol flowing over the float-chamber and dripping from the air inlet.

lilooding is generally caused by foreign matter finding its way on to the

seating of the

flwt-chamber needle.

It

can usually he removed by raisir12

the float needle, permitting the incoming petrol strel~m to wash awa) the

particles of grit,

and

then twisting the needle on its seating

a

few times with

the fingers; the seating should on no account he ground in.

General.

It

hill

he re:~lised from the for'egoing that the

S.11.

carhuretter

is

;I

very simple instrument and easily managed when understood.

On the

other hand, considerable damage can h'e done

if

it

is not tr'eated correctly.

We would ,emphasise that the three troubles previously outlined ar,e the

only ones that can

he

C~LISC~

by d'efects in the carhuretter, and

if

these points

are in order the carburetter should on no account he dismantled or altered,

sinc,e the trouble must lie elsewh,ere.

D

/

1

PAGE

FIFTY-NINE

Loading...

Loading...