7

3.2 Maintenance of Accessories

3.2-1 Maintenance of Cutter

(1) While installing a cutting tool, place a rag under it to avoid damaging the cutter or the table if

the cutter accidentally falls.

(2) Store cutting tools in wood or plastic box to avoid damaging the cutting edges.

(3) Verify spindle is turning in the proper direction – if viewed from below, the chuck should spin

counter-clockwise; otherwise, proper cutting action will be defeated. If unsure about direction

of rotation, use slow speed or watch carefully as machine comes to a stop.

(4) Before starting machine, move the workpiece near the cutter, then start machine and move into

position needed for milling.

(5) Keep cutting tools sharp. Dull cutters are hard on the machine, on the work piece, and destroy precision.

3.2-2 Tips for Using Accessories

(1) Keep shanks clean.

(2) Keep pairs of cutters and holders together whenever possible to increase operating confidence in

subsequent use.

(3) Use the wrenches supplied with the machine to tighten the drawbars and chucks to avoid damage that

can be caused by inappropriate tools.

(4) Use wrenches to tighten bolts. Never use pliers or hammers on machine tools.

3.1-3 Repairs and Maintenance

(

1) Keep a record of all machine repairs.

(2) Do not perform any repairs while the machine is running.

(

3) Inspect the machine regularly for proper operation; perform all repairs immediately.

(4) If you’re unsure about your ability to make repairs, contact your dealer’s service department

for assistance.

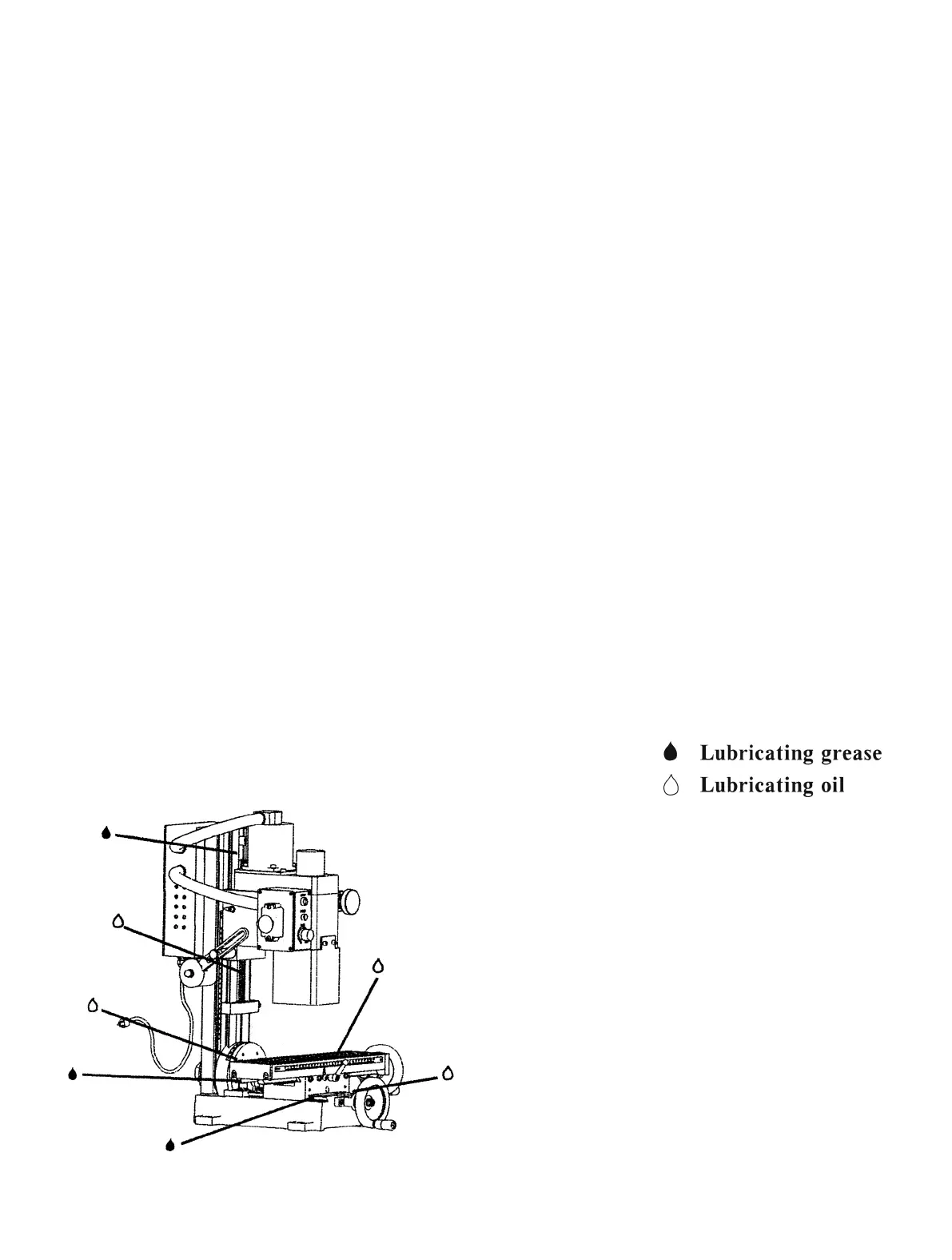

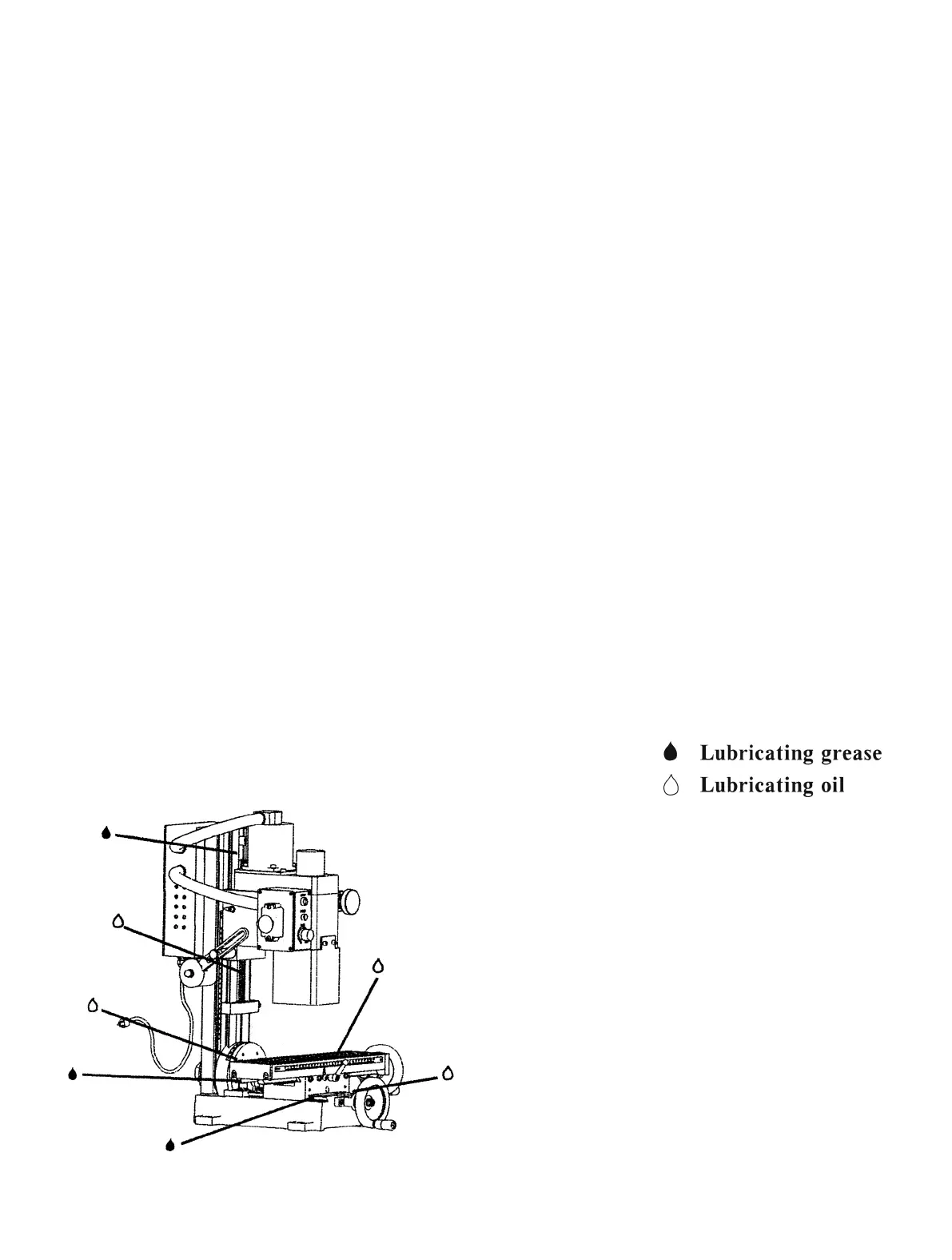

3.3 Lubrication

Be sure to keep all working parts properly lubricated:

USE LUBRICATING OIL

(1) Base and saddle seat sliding faces.

(2) Saddle seat/working table sliding faces.

(3) Column seat and connecting strut sliding faces.

(4) Headstock and spindle box sliding faces.

USE LUBRICATING GREASE

(1) X-Axis feed screw (saddle seat).

(2) Y-Axis feed screw (work table).

(3) Z-Axis feed gear rack (headstock).

After use, clean the work table and coat lightly with oil to protect from rust.

Loading...

Loading...