Appendix D: Fluid Compatibility Tables

fct-4 09/30/2010 LV1 User Manual D-2

Polyetheretherketone, one of the new high-strength engineering plastics. Has excellent chemical

resistance and structural properties. Very high temperature capability. Used for bearings, gaskets,

and back-up rings.

PEEK:

Has broadest chemical resistance of all plastic materials and outstanding temperature capability.

Limited strength and poor shape retention make PTFE a poor choice for sealing and load bearing

applications unless combined with other fillers such as glass fibers, carbon graphite, or

molybdenum disulfide.

PTFE: (Trade name, Teflon):

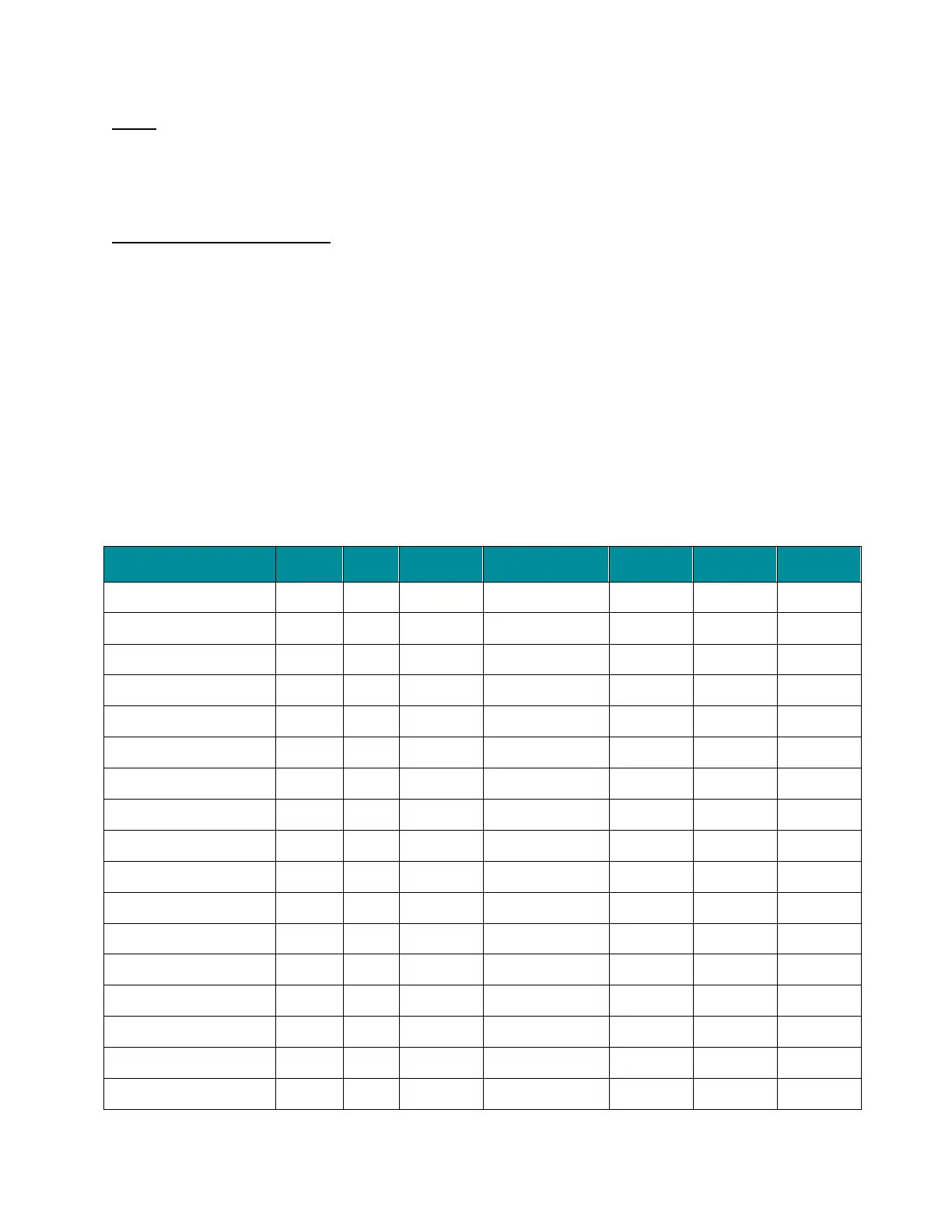

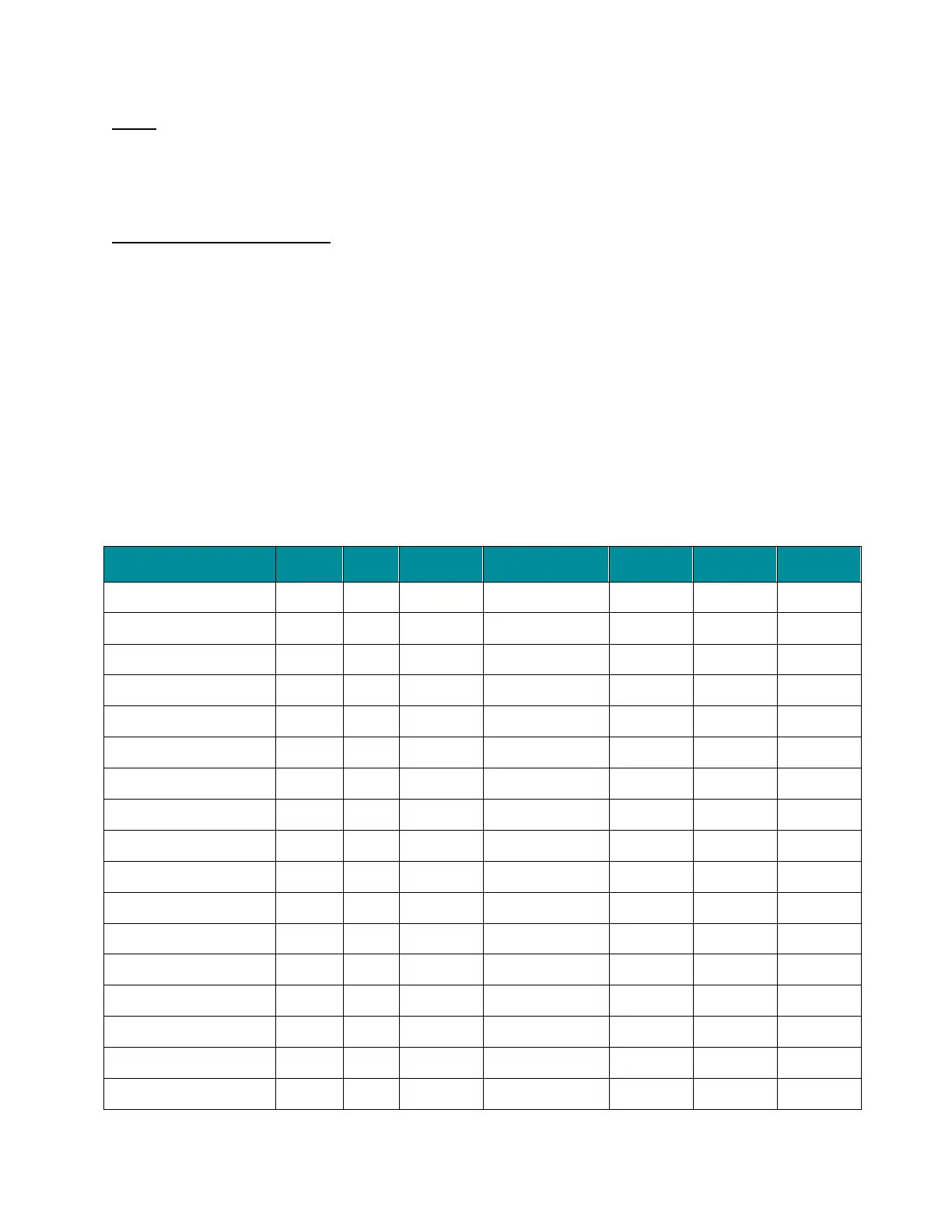

R = Recommended

M = Marginal

U = Unsatisfactory

X = Insufficient Data

L = Likely to be Compatible

Fluid Nitrile EPDM Neoprene Fluoroelastomer UHMWPE PEEK PTFE

Acetaldehyde U R U U X L R

Acetamide R R R U X X R

Acetic Acid M R R U R R R

Acetone U R M U R R R

Acetophenone U R U U X L R

Acetylene R R R R L R R

Acrylonitrile U U U U X R R

Ammonia R R R U R R R

Ammonium Hydroxide R R R R L R R

Amyl Acetate U M U U R L R

Anderol L-774 M U U R L L X

Antifreeze R R R R R R R

Aniline U R U M R R R

Ansul Ether M M U U X L L

Aroclors M R U R X L L

Askarel R U U R X L R

Asphalt M U M R L R R

Loading...

Loading...