Page 5 of 9

Step 5: Time is counting down; once time is up, the buzzer will send out a sound again, then open up the

heat platen (meantime the sounds stop).

Step 6: Work finish and take out the object. If you want to print on another object, place the object on press

bed and confirm the TIME and TEMPERATURE set as last time, then repeat above process. Unplug the

power cord when is machine is not in use.

Step 7: Consult the Transfer Paper instructions on whether to peel cold or hot, Here are suggested Pressing

time guidelines for different transfer paper.

Ink-Jet Transfer Paper (fabric) 14-18 seconds

Laser Copier/Printer Transfer Paper (fabric) 18-25

seconds Sublimation Transfers (onto Fabrics) 25-30

seconds Sublimation Transfers (onto FR-Plastic/Woods)

60-70 seconds

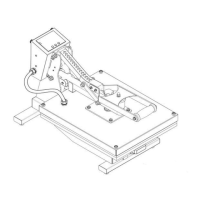

Step 8: Mouse pads, coasters and other thicker materials may also be pressed. Simply adjust the pressure

adjust gear - clockwise to increase pressure, and counterclockwise to decrease pressure.

5. Recommendations

1) Ceramic tile transfer: (Mugs & Plates transfer is similar)

Set temperature: 180℃.

Set time: 15 seconds

2) T-shirt transfer:

Set temperature: 180℃.

Set time: (for chemical fiber use sublimation transfer paper: 30-50seconds; for pure cotton use T-shirt transfer paper:

10-20seconds)

NOTE:

1) Please switch off the machine and unplug the power cord when the machine is not in use.

2) The heat platen will cool down to the room temperature, if heat press stays unused for more than 30 minutes.

3) The heat-releasing fan will automatically starts when the temperature of heat platen reaches 80 degree C

(176 degree F). It helps to reduce the temperature of electrical parts and prolong the service life of them.

4) For better maintenance of heat press, the maximum setting temperature is 210 degrees C (410 degrees F).

5) To avoid re-heating the first transfer when printing double sided T-Shirts, insert a sheet of cardboard in between

the shirt, adjust the height to less pressure, then press.

6) Heat platen may pivot slightly back and forth rotationally. This is due to movement allowance within the

clamp assembly, and is normal.

Loading...

Loading...