is located in a tight or separate room, additional ventilation

may be required. Install two permanently open grills, each

sized on the basis of one square inch free area per 1,000

BTU (but not less than 100 square inches) of the total input

rating of all gas utilization equipment located in the

confined space. One grille should be located within 12"

inches of the ceiling, the other within 12" of the floor.

If the gas utilization equipment is located in an area of

unusually tight construction, or if an exhaust fan, kitchen

ventilation system, clothes dryer and/or fireplace is installed

in the building, provisions must be made for an outside air

supply near the gas utilization equipment area. Install

permanently open grills sized at not less than one square

inch free area per 4,000 BTU of burner input. When

ventilating through horizontal ducts, grills should be sized

not less than one square inch free area per 2,000 BTU. In

any case, the minimum dimension of rectangular air ducts

shall not be less than 3 inches.

In Canada, for detailed ventilation requirements, refer

to standard CAN/CGA 1-B149.1 or .2 and/or local codes.

___________________________

II - Preparation of the Gas Utilization Equipment

Clean the appliance, heat exchanger interior,

combustion chamber, and flue connections. Remove all

adhering tars, scale, dirt and soot. Inspect for actual leaks

and/or potential leaks.

Cement all joints, including those in the gas utilization

equipment base and around door frames, to prevent

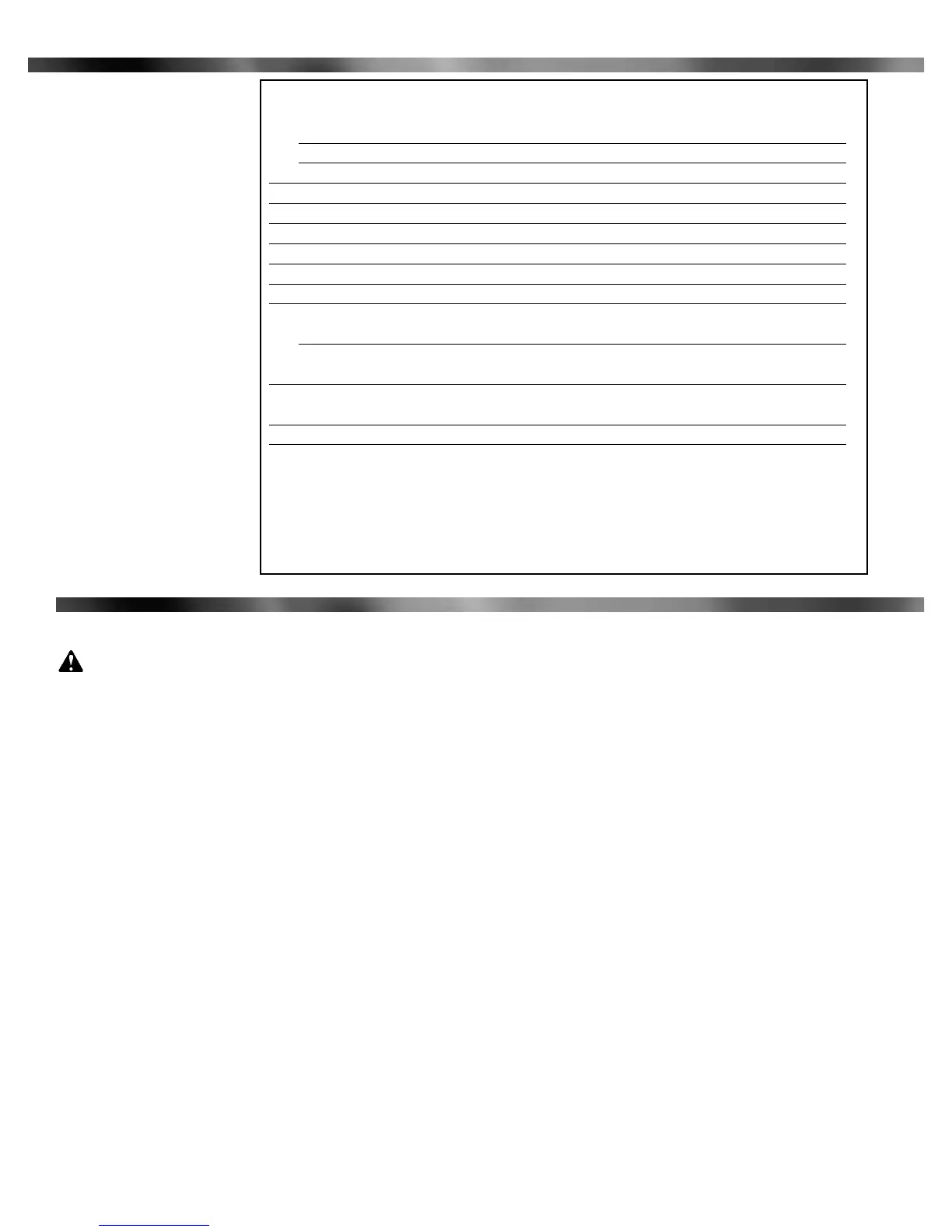

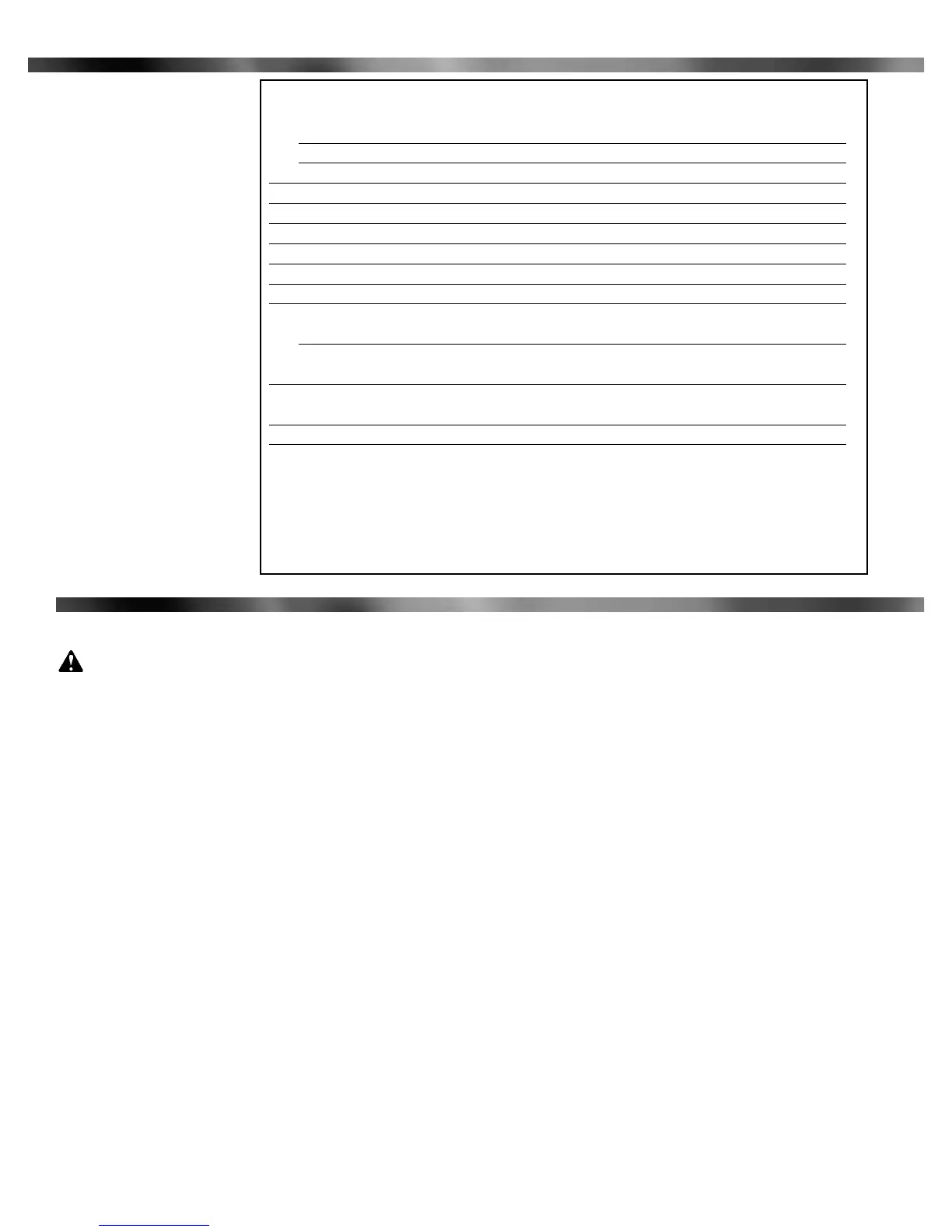

Part 1 Installation

Specifications

NATURAL or PROPANE Gas

Air Delivery

(Approximate air delivery at zero draft)

Maximum Firing Rate**

Minimum Firing Rate**

Tube Diameter

Tube Length

Combustion Chamber Size

100 MBH ***

200 MBH ***

300 MBH ***

Gas Pressure Required

NATURAL or PROPANE

Electrical Supply Standard

Flame Safety

Main Automatic Valve

EC 200 EC 300

40.0 SCFM* 60.0 SCFM*

200 MBH*** 300 MBH***

70 MBH*** 90 MBH***

4 inches 4 inches

7.50 inches 7.50 inches

Recommended Minimum W & H

8" W x 8" H

10" W x 10" H

14" W x 14" H

6.0" to 14.0" W.C. 6.0" to 14.0" W.C.

120/1/60, 2.0 Amps 120/1/60, 3.0 Amps

230 volts 50/60 hz **** 230 volts 50/60 hz ****

24V Electronic Flame Safety, with 100% shut-off, 30-

second pre-purge.

3 Function Redundant 3 Function Redundant

General information

CAUTION: The ECONOMITE EC Series is not intended for

outdoor installation and must be protected from excessive

moisture. Provide adequate clearance for service and proper

operation.

___________________________

Before installation, read these instructions carefully.

The EC 200 / 300 burner is a gas power burner designed for

firing natural or propane gas in most applications. The burner is

a self-contained unit consisting of a blower assembly, burner

head, ignition control and a combination gas valve. The burner

installation involves mounting the burner to the gas utilization

equipment, piping the gas train and connecting the power

supply. Every burner is operationally fire tested at the factory

prior to shipping.

___________________________

I - Ventilation

If the former automatic oil burner provided trouble-free

operation, then the gas utilization equipment area should have

sufficient air for combustion and the dilution of flue gases.

Nevertheless, the area must be checked:

Open basement or utility areas of normal construction,

without storm windows or tight doors, will generally allow

sufficient air infiltration. However, if the gas utilization equipment

2

Notes:

* SCFM=Standard Cubic Feet/Minute

** Ratings based on 1,000 BTU/cu. ft. NATURAL, 2500 BTU/cu. ft. PROPANE at Sea Level.

***1 MBH=1,000 BTU/Hr.

**** Available - Contact Factory

Derate burner for altitudes over 2,000 feet by 4% for each 1,000 feet above sea level.

Midco International Inc. - Chicago IL - www.midcointernational.com

Loading...

Loading...