8

Midco International Inc.

8471 15

MADE in the USA

Part 2 Service

_________________________________________

WARNING: BE SURE THAT THE MANUAL VALVE AND BURNER DISCONNECT SWITCH

ARE TURNED OFF BEFORE ANY PARTS ARE REMOVED FOR SERVICE.

The Ignitor and Regulator Assembly is removed as a unit. Disconnect the ignitor gas line and electrode

wires, remove the two mounting screws and pull out the assembly.

- When the ignitor gas pressure is in the proper range (see Table 3) and the electrodes are adjusted

to the dimensions shown in Figure 5, any ignition problems are usually caused by lint, dust, corrosion,

cracked electrode insulators, foreign matter in the blast tube or deterioration of ignitor ports in

Retention Plate.

- Ignitor trouble will be evidenced by failure of main burner ignition. It may cause frequent Electronic

Control lockout. Check for dirt in the ignitor air and mixture passageways and check for obstructions in

the ignitor ports. Also check electrode adjustments (see Figure 5). Replace any severely burned parts.

- Proper operation of the fl ame sensor rod can be checked by measuring the fl ame current. With the

Electronic Control energized, a good reading should run steady 2 or more microamps.

- When servicing, clean the Ignitor Retention Plate ports and blow out the internal air and gas passages.

Clean the Electrode Insulators and check them for hairline cracks. Also check the electrode ends and

the Ground Barrier for serious corrosion or loss of metal. Replace any defective parts.

- Make sure that there is no debris in the Blast Tube that could short out the Spark or Flame Electrode.

- Clean the Ignitor Gas Orifi ce in Tee Orifi ce Fitting (see Figure 5) and check that the orifi ce size is

correct per Table 3.

- Check that the electrode ends are positioned and that the gap between the end of each electrode

and the ground barrier is spaced per Figure 5.

- Check that the Ignitor Air Defl ector is at the correct angle (45°). See Figure 4.

- Inspect the electrode wire insulation for cracks or worn areas, or any contact with the burner frame.

Dampness will facilitate electrical leakage to ground, which will cause ignition or fl ame signal failure.

TYPE OF IGNITOR RECOMMENDED IGNITOR IGNITOR

GAS ORIFICE DIA. GAS PRESSURE GAS RATE

Natural . 070 ( #50 DR ) 3.5″ W.C. 13 MBH

Propane . 063 ( #52 DR ) 3.5″ W.C. 15 MBH

SPARK TEST—Main Manual Shut-Off Valve must be off . Place the Ignitor Assembly on top of the

burner with the electrode ends visible and good metal to metal contact between the Ignitor Mounting

Plate and the burner chassis.

VIII Ignitor and

Regulator Assembly

Table 3 Ignitor Firing Rate

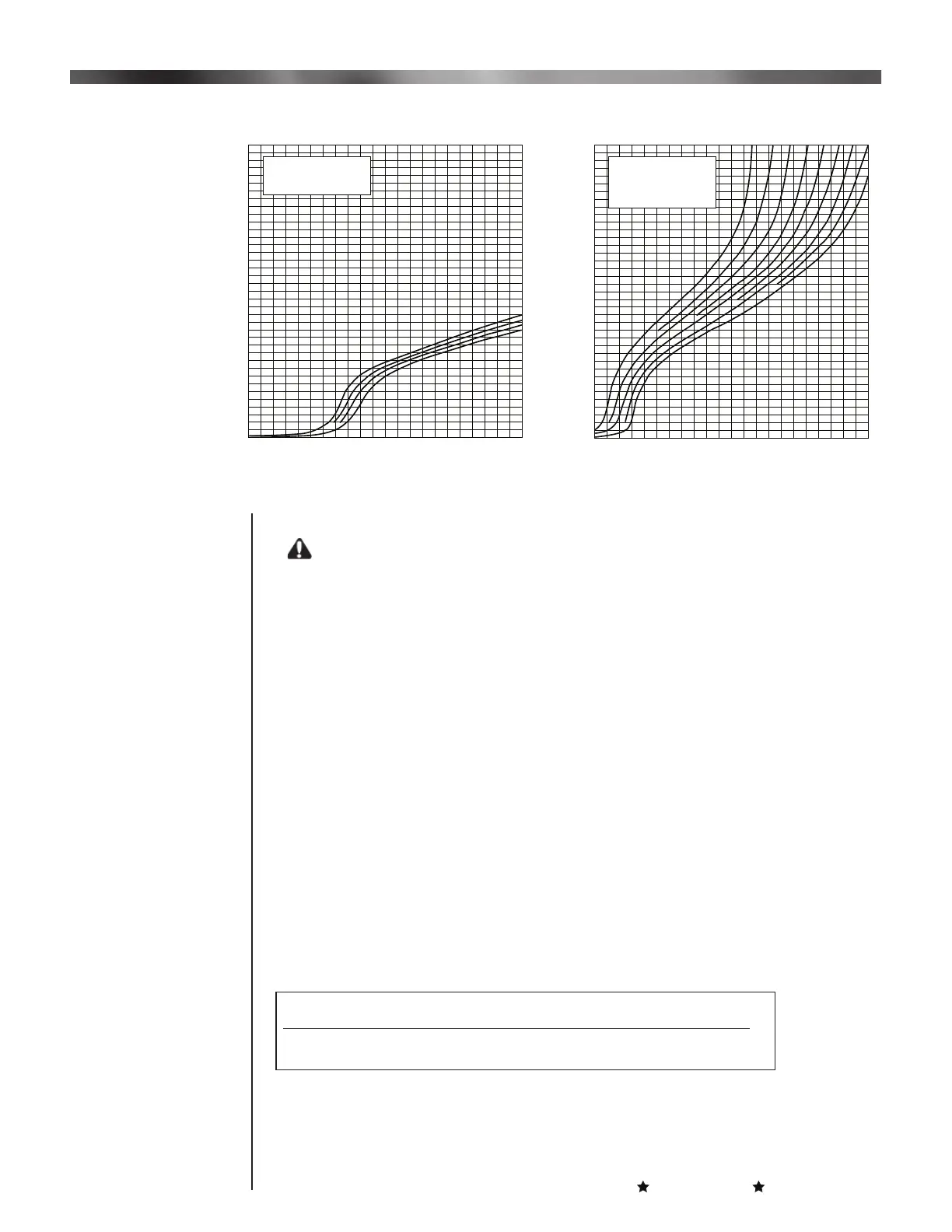

100 200 300 400 500 600 700 800 900 1000 1100 1200

14

12

11

10

9

8

7

6

5

4

3

2

1

13

0

8.0

10.0

9.0

11.0

Input in MBH

Input Adjuster Setting in Numbers of Turns from Full Closed

15

19

16

17

18

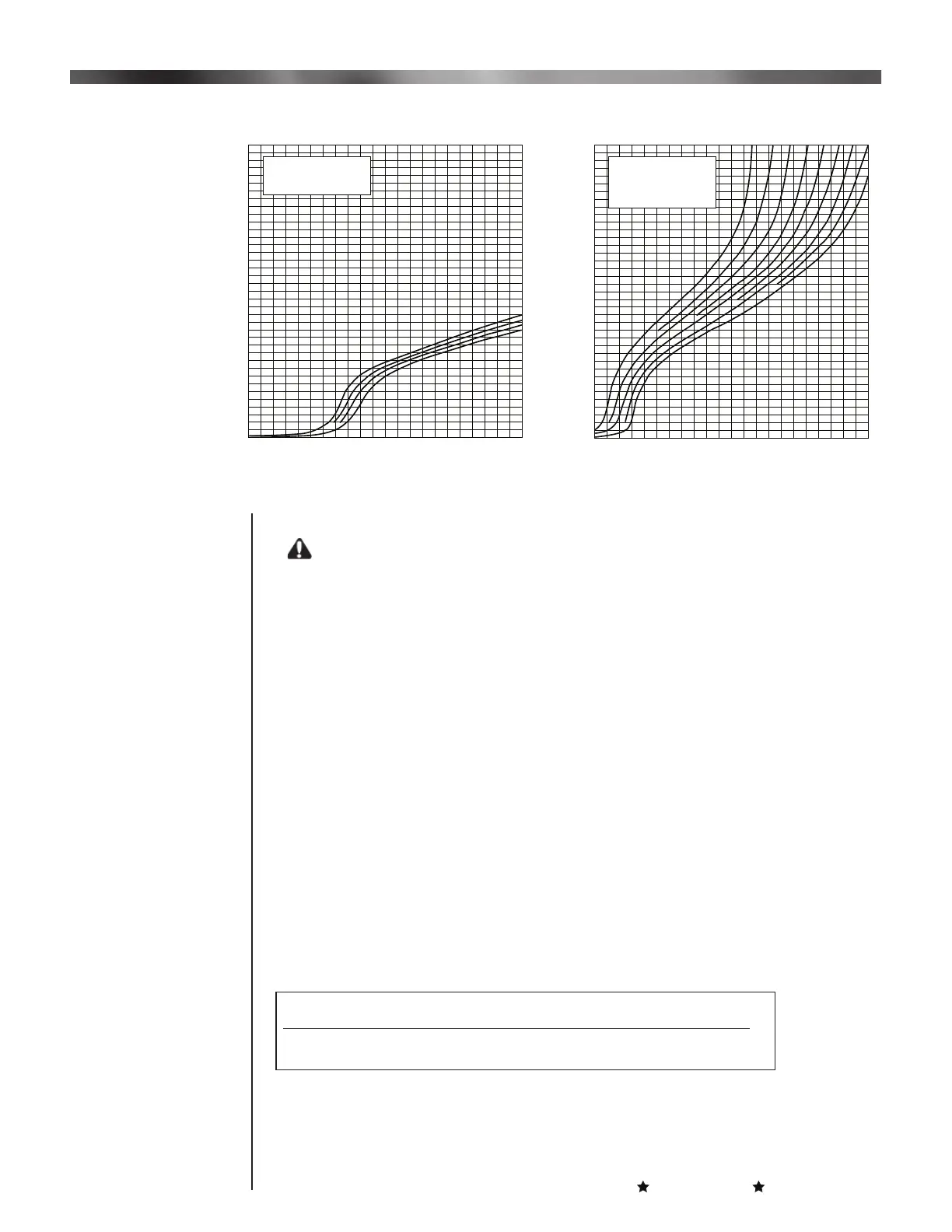

100 200 300 400 500 600 700 800 900 1000 1100 1200

14

12

11

10

9

8

7

6

5

4

3

2

1

13

0

6.

Input in MBH

Input Adjuster Setting in Numbers of Turns from Full Closed

15

19

16

17

18

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

Propane Gas

2,500 BTU/Cu. Ft.

(with 5/8” Main Gas Port)

Natural Gas

1,000 BTU/Cu. Ft.

(with 5/8” Main Gas Tube

only, No Gas Port)

Gas Pressure at Main automatic Valve (Inches Water Column)

Table 2 Firing Rate Curves

VII Initial Start

Up/Adjustment

Continued

Loading...

Loading...