MCAC-CTSM-2018-1 Flooded type water cooled screw chiller (MIC)

93

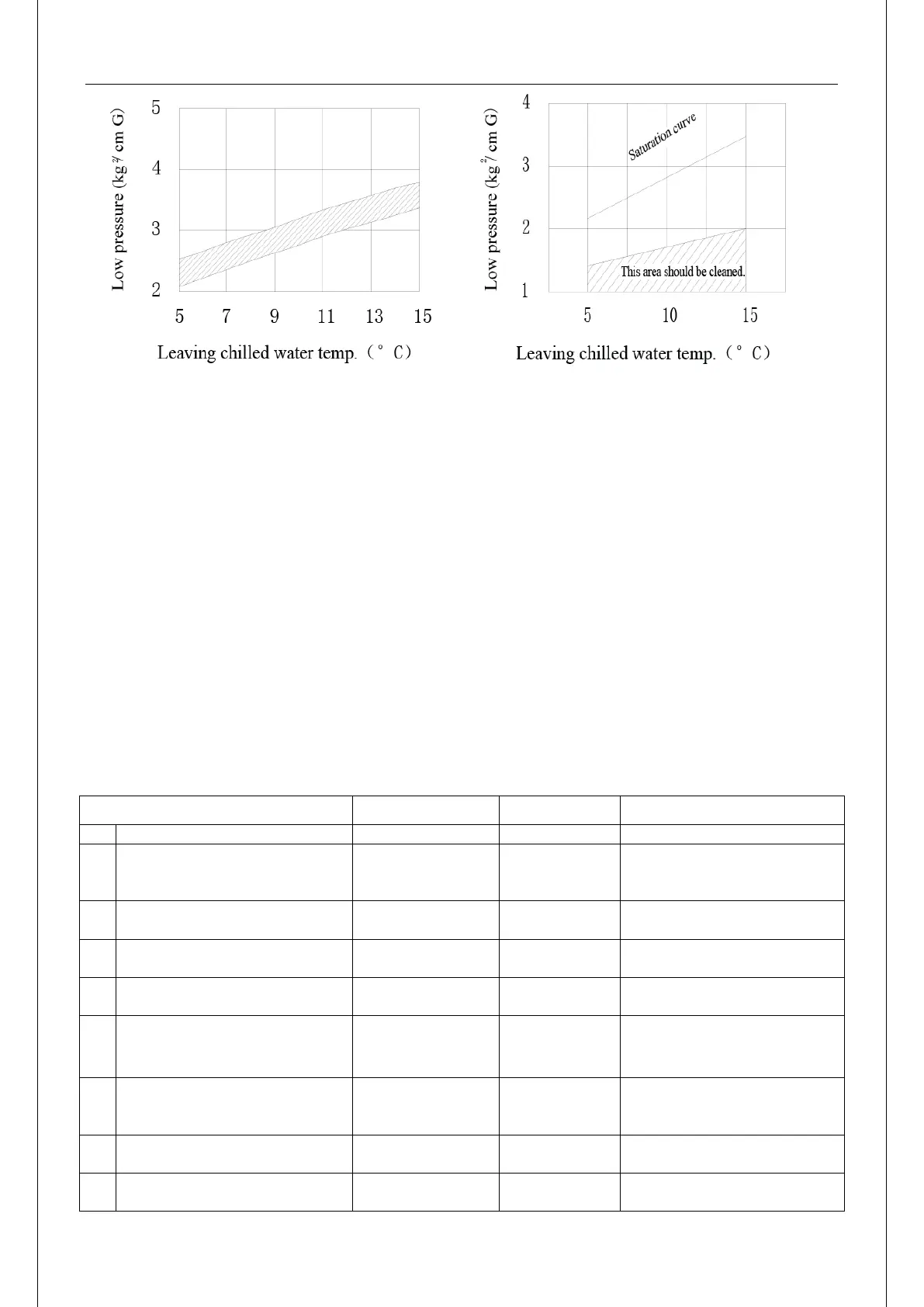

Fig.27 Low pressure at full load (standard unit)

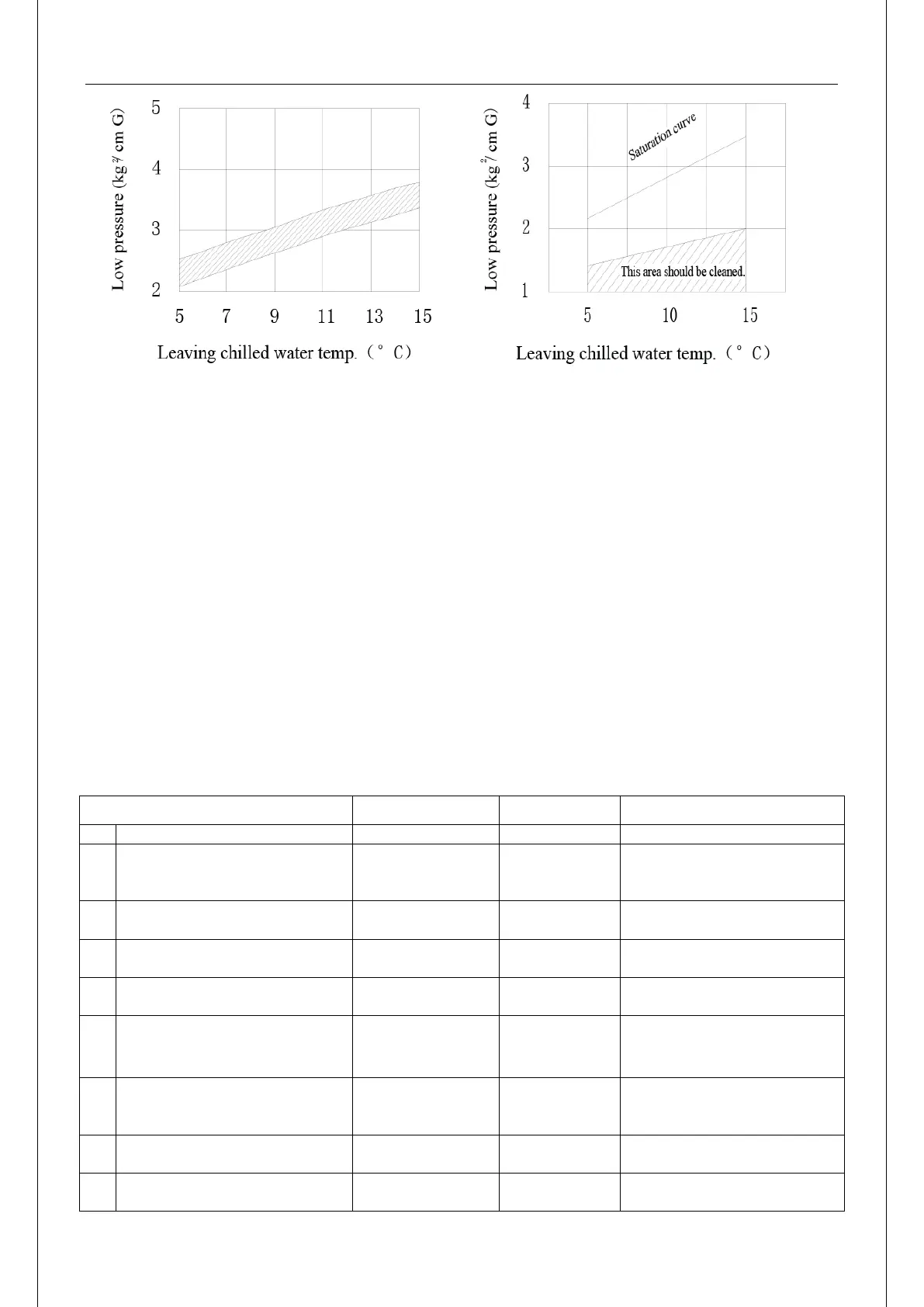

Cleaning work must be done a lot of scale is found. Physical and chemical cleaning can be chosen

according to the device you have. Generally, chemical cleaning is much easier to carry out. Methods are

as below. Arrange for a qualified water treatment specialist to develop and monitor a treatment program.

a) Cycle under normal temp. (A):

(Volume of condenser+ volume of pipes+ volume of container)×1/3

Note: concentration of detergent ——33%

b) Cycle under normal temp. (B):

(Volume of cooling tower flume + volume of condenser+ volume of pipes)×1/10

Note: concentration of detergent ——10%

Warning: When you do cleaning while the unit stops, the volume of the cooling tower flume can be 1/2

or 1/3 of rated value. The volume of cooling tower flume should keep at the rated value if cleaning is

performed when the unit is running. Midea assumes no responsibility for pressure vessel damage

resulting from untreated or improperly treated water.

Requirement for cleaning and maintenance

Generates insoluble CaSO

4

Soft fluid deposit may be

caused by ions iron or

aluminum

Water with much Ca

2+

and

Mg

2+

Easily generates hard scale.

Corrosive to copper and

iron.

Water with much SO

4

2-

and

SiO

2

2-

Generates hard CaSO

4

and

CaSiO

2

Generates deposits Fe(OH)

3

and Fe

2

O

3

Generates sulfide, ammonia

and marsh gas, especially

H

2

S which corrodes copper.

Water with organic

substances

Exhaust gas from auto,

chemical factory, plating

Copper tubes of condenser

may be eroded and

Loading...

Loading...