MCAC-VTSM-2015-10 R410A All DC Inverter V5 X Series 50Hz

Installation 115

3) When adopting rubber/plastic or other materials, insulation thickness shall meet design requirements

according to relevant calculations.

8. Brazing cautions

Ensure system is purged with sufficient nitrogen throughout all brazing operations. Correct use of nitrogen

during the brazing process prevents the formation of oxidation on the inside in copper piping. An oxidized

film adversely affects valves and compressors in the refrigerating system and prevents proper operation.

The nitrogen pressure should be set to 0.02MPa with a pressure-reducing valve.

Do not use anti-oxidants when brazing the pipe joints. Residue can clog pipes and damage equipment.

Do not use flux when brazing copper-to-copper refrigerant piping. Use phosphor copper brazing alloy (BCuP)

which does not require flux.

Flux has an extremely harmfully influence on refrigerant pipe systems. For instance, if chlorine based flux is

used, it will cause pipe corrosion, if the flux contains fluorine, and it will deteriorate the lubrication properties

of refrigerant oil.

9. Remove dirt or water in the piping

Make sure there is no dirt or water in the piping system before connecting the piping to the outdoor units.

Flush the system with high pressure nitrogen, never use the outdoor units' refrigerant for this purpose.

10. Gas tightness test

10.1 Purpose and operation procedure of air tightness test

10.1.1 Purpose

Identify the source of leaks, make sure there is no leakage in system to prevent system fault due to leakage of

refrigerant.

10.1.2 Operation tips

Subsection detection, overall pressure-keeping, grading pressurization.

10.1.3 Operation procedure

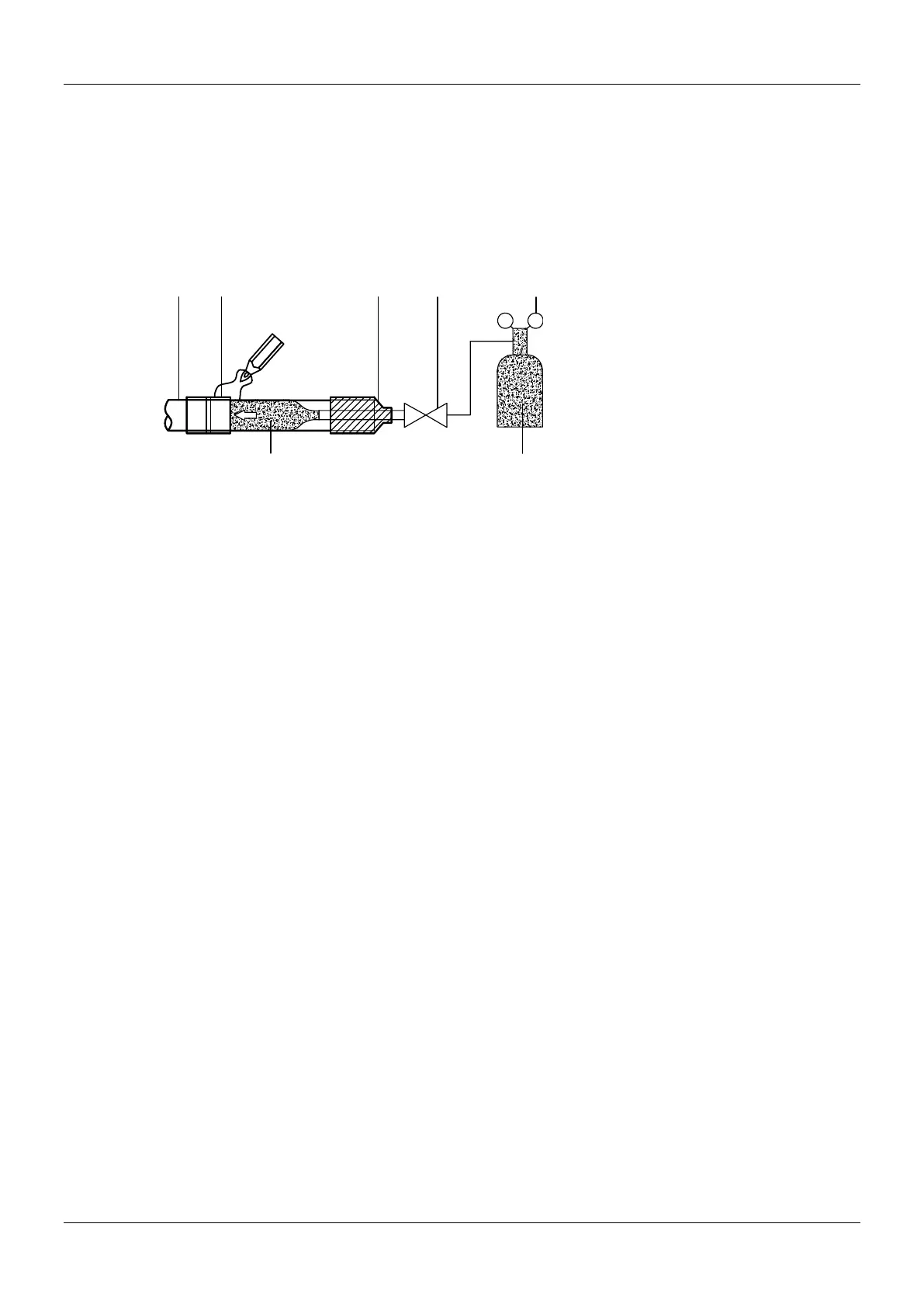

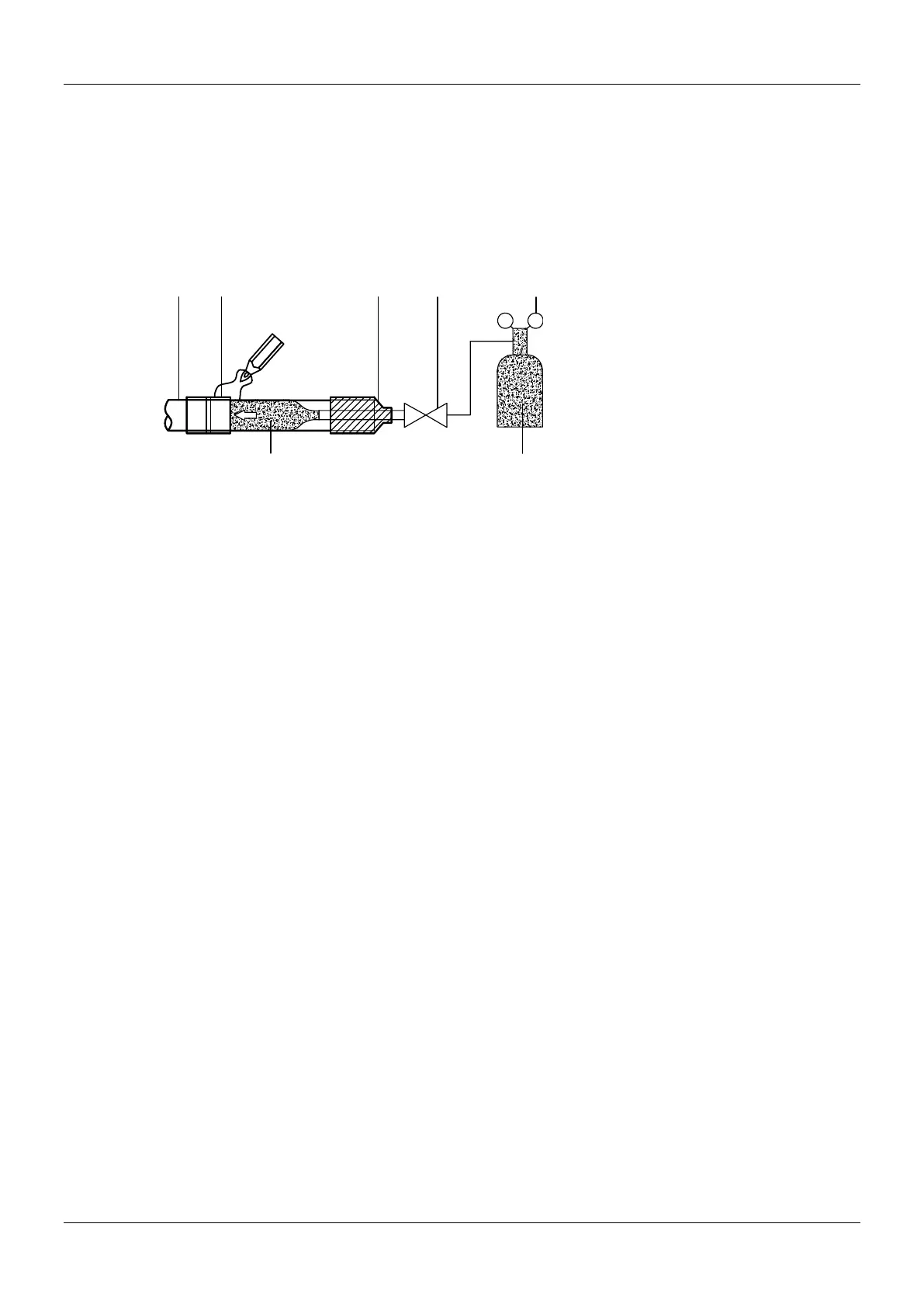

1. After piping of indoor unit has been connected, weld port of high-pressure side piping.

2. Weld low-pressure side piping with connector for pressure gauge together.

3. Charge nitrogen slowly into pressure gauge connector to conduct air tightness test.

10.2 Operation of air tightness test

10.2.1 Operation procedure

1. When conducting air tightness test, make sure that gas and liquid piping are fully closed to prevent nitrogen

from entering the system. Both gas and liquid valve need to be strengthened before pressurization.

2. Each refrigerant system shall be slowly pressurized from both sides of gas and liquid pipe.

3. Use dry nitrogen to conduct air tightness test. Phase-in control diagram of pressurization is as follows:

1 Refrigerant pipe

2 Part to be brazed

3 Taping

4 Hands valve

5 Pressure-reducing valve

6 Nitrogen

Loading...

Loading...