INITIAL OPERATING

Mains connection

It is important to ensure that the mains supply voltage is in accordance with the voltage to which the machine is

built. If the machine can be adjusted for use on several different voltages then the machine must be checked to

confirm that it has been set to the correct voltage.

Connection of gas bottle

Use only gas bottles with a max. height of 100 cm. If larger bottles are used the machine may tip over.

Configuration

MIGATRONIC disclaims all responsibility for damaged cables and other damages related to welding with

under sized welding torch and welding cables measured by welding specifications e.g. in relation to per-

missible load.

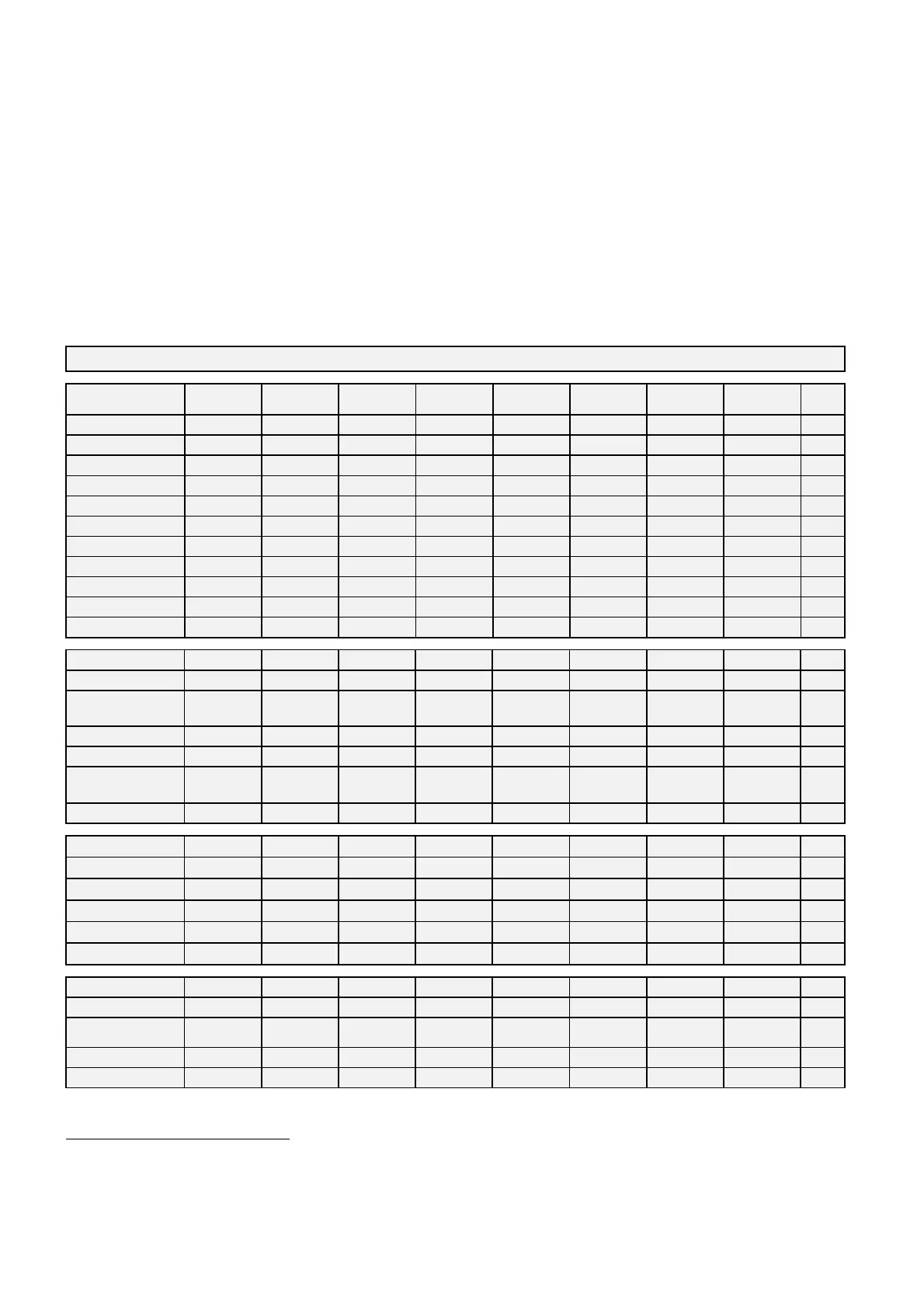

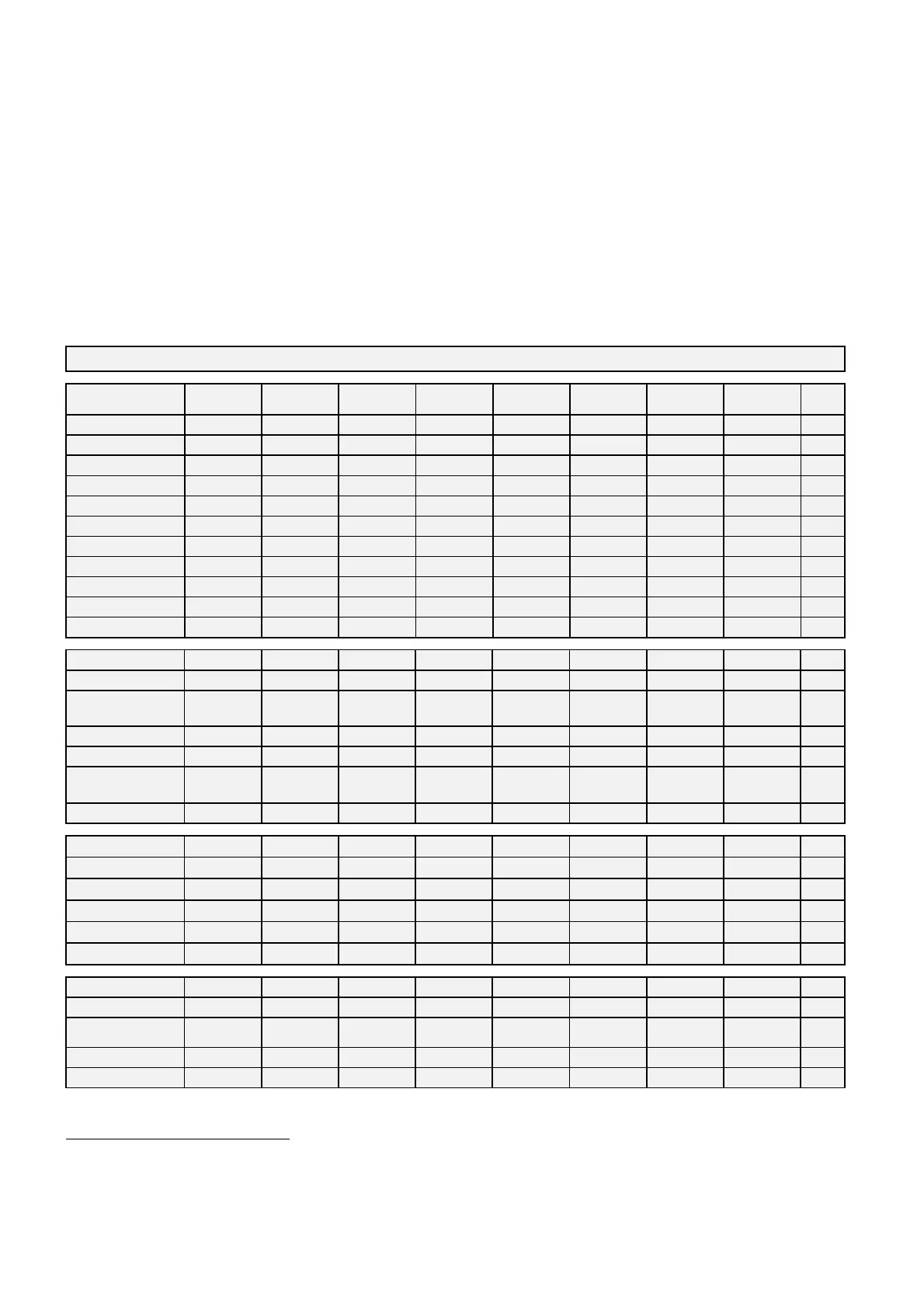

TECHNICAL DATA

We reserve the right to changes

Type Automig

181

Automig

183

Automig

221

Multimotive

220

Automig

223

Automig

231

Automig

271

Automig

273

Units

Current range 30-160 20-180 20-180 20-200 20-200 20-200 20-250 20-250 A

Voltage adjustment 4 7 7 20 10 11 9 10

Duty cycle, 100% 40 65 60 105 105 85 110 140 A

Duty cycle, 60% 50 85 75 125 125 105 150 165 A

Duty cycle, 35% 60 110 90 150 150 145 190 200 A

Duty cycle, 30% 155 155 A

Duty cycle, 20% 230 A

Duty cycle, 14% 150 A

Duty cycle, 15% 200 A

Duty cycle, 6% 160 A

Open circuit voltage 19-33 14-30 14-41 14-30 14-30 17-47 14-54 15-34 V

1

Mains voltage

230 400 230 400 400 230 230 400 V

Fuse

10 10 16 10 10 16 35 10 A

Mains current,

effective

4.3 2.5 11.5 4.0 4.0 14.7 21.2 5.9 A

Mains current, max.

17.4 5.7 30.8 7.3 7.3 38 47.5 10,0 A

Consumption, 100%

0.7 1.3 1,7 2.3 2.3 2.3 2.8 3.4 kW

Consumption, open

circuit

<10 <10 <10 <10 <10 <10 <10 <10 W

Efficiency

0.85 0.84 0.85 0.85 0.85 0.85 0.80 0.82-0.84

Wire dimension 0.6-0.8 0.6-1.0 0.6-1.2 0.6-1.2 0.6-1.2 0.6-1.2 0.6-1.2 0.6-1.2 mm

Wire reel capacity 5-15 5-15 5-15 5-15 5-15 5-15 5-15 5-15 kg

Wire speed 2-12 2-12 2-12 2-14 2-14 2-12 2-15 2-15 m/min

2

Spot welding time 0.15-2.5 0.15-2.5 0.15-2.5 0.15-2.5 0.15-2.5 0.15-2.5 0.15-2.5 sec.

2

Stitch welding time 0.15-2.5 0.15-2.5 0.15-2.5 0.15-2.5 0.15-2.5 0.15-2.5 0.15-2.5 sec.

Burn-back 0.05-0.5 0.05-0.5 0.05-0.5 0.05-0.5 0.05-0.5 0.05-0.5 0.05-0.5 0.05-0.5 sec.

3

Application class S S S S S S S S

4

Protection class IP21 IP21 IP21 IP21 IP21 IP21 IP21 IP21

Standards

EN/IEC60974-1

EN50199

EN/ EC60974-1

EN50199

EN/IEC60974-1

EN50199

EN/IEC60974-1

EN50199

EN/ EC60974-1

EN50199

EN/IEC60974-1

EN50199

EN/IEC60974-1

EN50199

EN/IEC60974-1

EN50199

Dimensions, lxwxh 72x38x70 72x38x70 72x38x70 72x38x70 72x38x70 72x38x70 90x44x71 72x38x70 cm

Weight 52 57 54 64 64 54 71 66 kg

1

Delivery for other mains voltages is possible

2

The functions 4-times, spot and stitch welding can only be found on some machine versions

3

Meets the demands made for machines which are to operate under special working conditions

4

This machine is designed for indoor operation and meets the requirements of protection class IP21.

Loading...

Loading...