Do you have a question about the Miller Electric Maxstar 200 STR and is the answer not in the manual?

Explains the meaning of warning symbols used in the manual.

Identifies potential hazards associated with arc welding processes and equipment.

Details additional symbols for safe installation, operation, and maintenance.

Lists California Proposition 65 warnings regarding chemicals in welding products.

References key safety standards and organizations for welding equipment.

Discusses electromagnetic fields and their potential effects during welding.

Defines the meaning of various warning labels found on the equipment.

Details the WEEE label for proper disposal of electrical and electronic equipment.

Provides information on the manufacturer's rating label and its components.

Explains common symbols and definitions used in the manual.

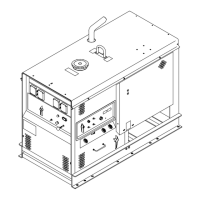

Lists the technical specifications of the welding power source.

Illustrates the volt-ampere output characteristics of the machine.

Explains duty cycle limitations and procedures for preventing overheating.

Provides guidelines for selecting a suitable and safe location for the unit.

Details weld output terminals and how to select appropriate cable sizes.

Describes the function and wiring of the remote 14 receptacle.

Illustrates how to make TIG Lift-Arc DCEN connections for welding.

Shows how to make Stick DCEP connections for welding operations.

Provides guidance on electrical service requirements and input power.

Details the procedures for connecting single-phase and three-phase input power.

Step-by-step guide for performing stick welding operations.

Chart for selecting appropriate electrodes and amperage settings.

Explains the scratch start technique for initiating an arc.

Details the tapping technique for initiating an arc.

Guidance on proper positioning of the electrode holder for welding.

Illustrates and describes common characteristics of poor weld beads.

Illustrates and describes characteristics of good weld beads.

Explains factors influencing weld bead shape, including angle and speed.

Describes correct electrode movement techniques for various weld joints.

Provides guidelines and illustrations for welding butt joints.

Illustrates procedures and techniques for welding lap joints.

Details the process and techniques for welding tee joints.

Explains how to perform a weld test to check joint integrity.

Identifies causes and corrective actions for porosity in welds.

Addresses causes and solutions for excessive spatter during welding.

Explains how to troubleshoot and correct incomplete fusion issues.

Provides solutions for problems related to lack of weld penetration.

Details how to resolve issues with excessive weld penetration.

Offers solutions for troubleshooting burn-through during welding.

Addresses causes and corrections for waviness in the weld bead.

Explains how to troubleshoot and prevent weld distortion.

| Brand | Miller Electric |

|---|---|

| Model | Maxstar 200 STR |

| Category | Welding System |

| Language | English |