Do you have a question about the Miller Electric PRO 300 CAT and is the answer not in the manual?

Explains hazard symbols and their meanings for safety.

Details risks associated with arc welding processes and electrical safety.

Outlines dangers related to the engine, including fuel, battery, and moving parts.

Details dangers associated with compressed air usage.

Covers hazards indicated by specific symbols for unit setup and use.

States warnings required by California law regarding chemical hazards.

Lists key safety standards and their sources for reference.

Discusses electromagnetic fields and precautions for users.

Explains the meaning of various warning labels found on the equipment.

Provides a comprehensive guide to symbols used in the manual and on the equipment.

Details technical specifications for welding, power output, and engine.

Provides physical dimensions, weight, and safe operating angles.

Illustrates the voltage and amperage output capabilities for different welding modes.

Shows typical fuel usage based on weld output and operating conditions.

Explains duty cycle ratings and warnings about overheating the unit.

Displays the generator's AC power output capabilities at different voltage modes.

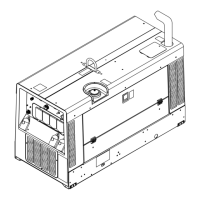

Covers the initial placement and movement considerations for the welding generator.

Provides instructions and methods for securely mounting the generator.

Explains the critical process of grounding the generator to its vehicle frame.

Shows where to find the unit's rating label and its importance.

Details the correct installation procedure for the exhaust pipe.

Guides through the process of preparing a dry charge battery for use.

Provides instructions for properly connecting the unit's battery.

Lists essential checks to perform on the engine before starting for safe operation.

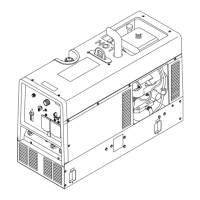

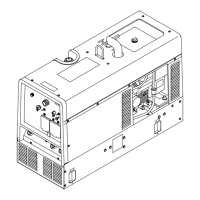

Explains how to connect welding cables to the correct output terminals.

Provides a chart and guidelines for choosing appropriate weld cable sizes.

Details how to connect remote controls to the RC14 receptacle.

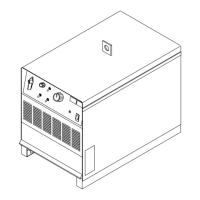

Identifies and illustrates the various controls on the front panel.

Provides detailed explanations of each front panel control's function.

Explains the function and settings of the process/contactor selection switch.

Details the specific procedure for initiating welding with Lift-Arc technology.

Explains how to use remote controls to adjust voltage and amperage.

Describes the available power receptacles and their ratings.

Outlines a schedule for regular maintenance tasks and checks.

Details the maintenance schedule and recommended service intervals for the engine.

Provides instructions for cleaning or replacing the air cleaner element.

Explains how to inspect and clean the spark arrestor muffler.

Guides on how to service the engine's cooling system, including coolant changes.

Describes how to adjust the engine speed on non-automatic idle models.

Explains engine speed adjustment for models equipped with automatic idle.

Covers maintenance procedures for the fuel and lubrication systems.

Explains the overload protection devices (breakers, fuses) and their functions.

Details how to inspect and replace generator brushes.

Explains diagnostic help codes displayed by the voltmeter/ammeter.

Provides solutions for common welding and generator power issues.

Lists common welding output problems and their remedies.

Lists common generator power output issues and their remedies.

Lists common engine starting, running, and stopping issues and remedies.

Addresses engine performance issues like slow stopping or idling problems.

Explains what wetstacking is and the conditions under which it occurs.

Provides a step-by-step guide for the engine run-in process using a load bank.

Details the engine run-in procedure utilizing a resistance grid.

Advises on selecting appropriate electrical equipment for generator use.

Provides guidance on grounding the generator when connecting to building electrical systems.

Explains how to calculate power requirements for various equipment.

Lists typical power requirements for different types of industrial motors.

Lists typical power requirements for farm and home equipment.

Lists typical power requirements for contractor equipment.

Explains how to determine the power needed to start various motors.

Provides guidelines on generator load limits and starting procedures.

Shows typical wiring connections for supplying standby power from the generator.

Provides charts for selecting appropriate extension cords based on current and length.

| Brand | Miller Electric |

|---|---|

| Model | PRO 300 CAT |

| Category | Welding System |

| Language | English |

Loading...

Loading...