ONLY 1 PERSON PER ANCHORAGE IS PERMITTED AT ONE TIME.

CONNECTORS USED WITHIN THE SYSTEM MUST BE ABLE TO

LB515 REV. A

WARNING!

SUPPORT 5,000 LBS. THE USE OF NON-APPROVED

COMPONENTS MAY CAUSE SERIOUS INJURY OR DEATH.

ATTACH LIFELINE HERE

HITCH PIN

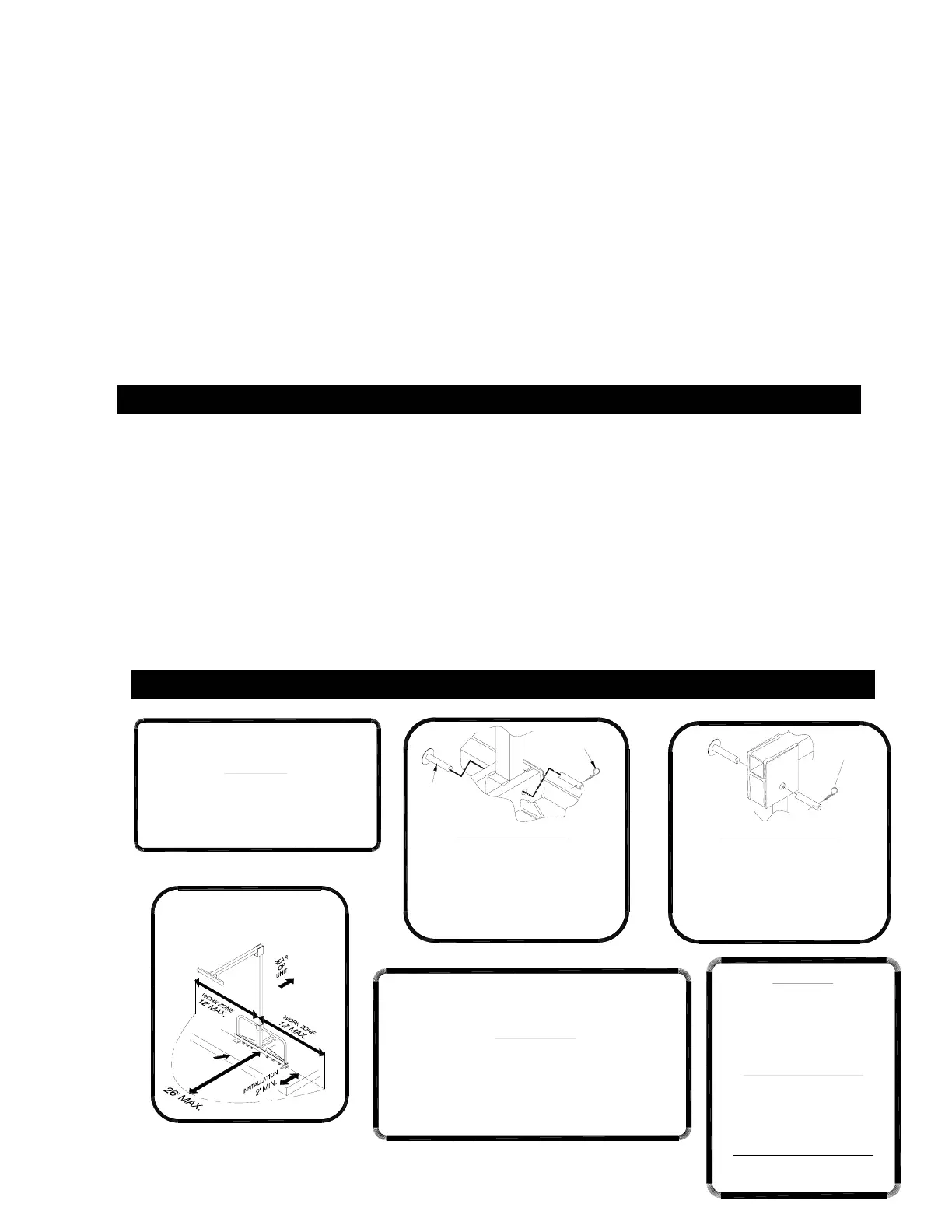

HORIZONTAL BOOM INSTALLATION

1. READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS

LB516 REV. A

BEFORE USING.

2. INSERT PUSH PIN THROUGH HORIZONTAL BOOM AND

INSTALL HITCH PIN THROUGH PUSH PIN AS SHOWN.

WARNING: BE SURE THE HITCH PIN HAS BEEN INSTALLED.

FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY

OR DEATH.

PUSH PIN

HITCH PIN

WARNING: BE SURE THE HITCH PIN HAS BEEN INSTALLED.

LB517 REV. A

FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY

OR DEATH.

VERTICAL BOOM INSTALLATION

AND INSTALL HITCH PIN THROUGH PUSH PIN AS SHOWN.

2. INSERT PUSH PIN THROUGH THE FRAME, VERTICAL BOOM

PUSH PIN

1. READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS

BEFORE USING.

LB518 REV. A

MAY RESULT IN SERIOUS INJURY OR DEATH.

FAILURE TO FOLLOW MANUFACTURER'S INSTRUCTIONS

USING ONLY ONE LIFTING RING MAY CAUSE THE DEVICE TO

BECOME UNSTABLE OR UNBALANCED WHILE LIFTING.

WARNING!

DO NOT USE FOR FALL PROTECTION.

LIFTING RINGS

BOTH LIFTING RINGS MUST BE USED TO LIFT THE DEVICE.

BRAKE ENGAGEMENT:

ROTATE BRAKE HANDLE CLOCK-

WISE UNTIL HANDLE HAS

STOPPED.

ENGAGED BRAKES BEFORE EACH

USE. FAILURE TO DO SO MAY

RESULT IN SERIOUS INJURY

OR DEATH.

REVERSE ABOVE PROCEDURES

BRAKE DISENGAGEMENT:

LB520 REV. A

WARNING!

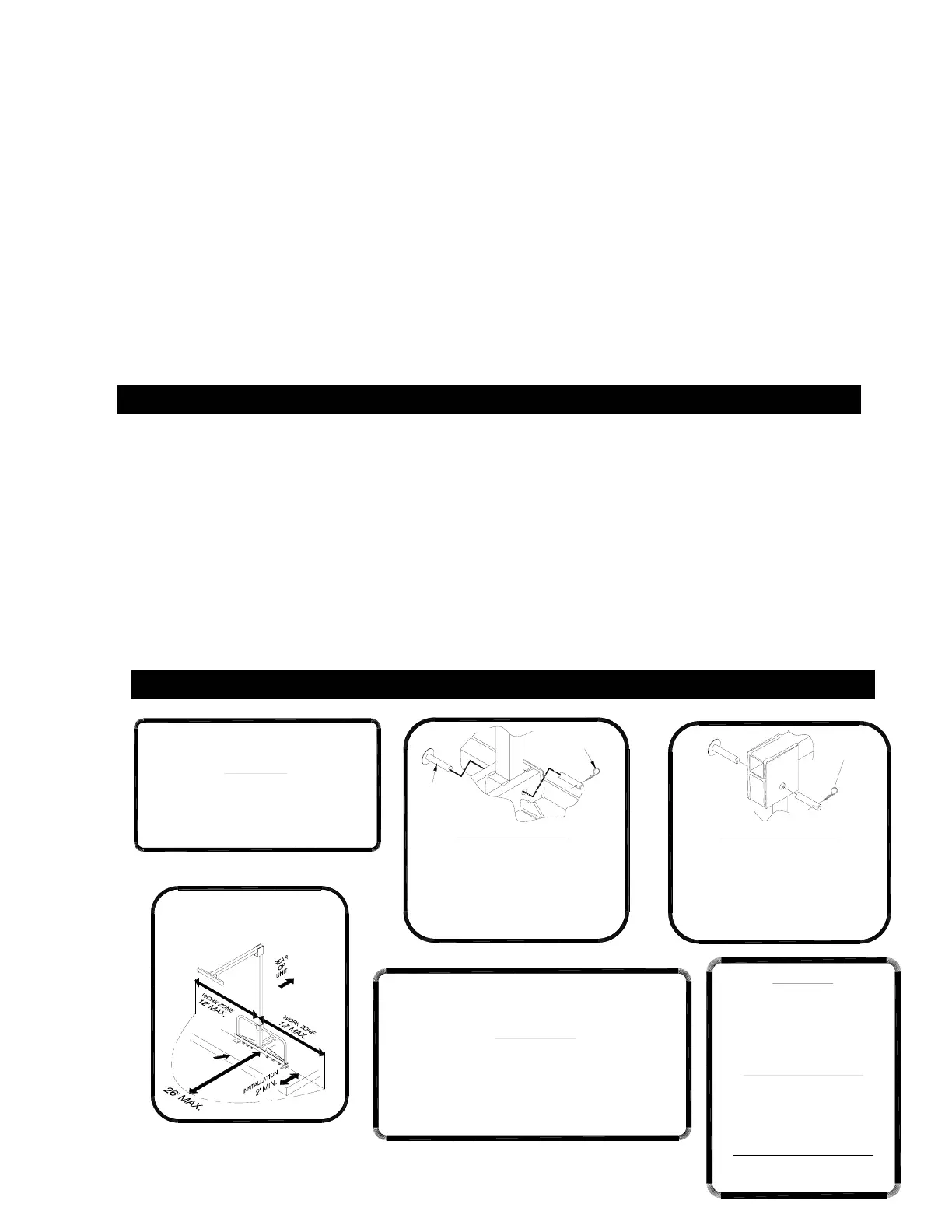

WARNING!

DO NOT EXCEED SAFE WORK ZONE

LB530 REV. A

MAY RESULT IN SERIOUS INJURY OR DEATH.

FAILURE TO FOLLOW MANUFACTURER'S INSTRUCTIONS

LEADING

EDGE

4. Inspect for malfunctioning components, broken or missing pins and fasteners. Replace if

5. at each rotates and moves freely and inspect for cuts, breaks, broken

ed.

ise to a complete stop.

8. m and all personal fall protection according to the manufacturer’s instructions.

Forma entire system and all

co

em and components

d

again for employee protection until inspected and determined by a competent person to be

ARNING: If inspection reveals a defect in condition, immediately remove the unit from service.

A. S

Servicing must only be carried out by a qualified person trained in the inspection and replacement of

nd all components of the system must be removed from service if

es. Contact Dalloz Fall Protection at 1-800-873-5242 if there are any

questions.

g, clean the unit to remove any dirt, grease or other materials that may have

ccumulated. Store in a clean dry area when not in use.

necessary.

Inspect wheels to ensure th

areas, excessive wear. Also, ensure that each wheel is securely fasten

6. Inspect brake jacks to ensure that each works properly and is capable of raising the unit when

crank handle has been rotated clock-w

7. Inspect all welds through out the unit for cracks, breaks, or corrosion.

Inspect syste

l Inspection: A competent person must perform an annual inspection of the

mponents.

Note: If the system has arrested a fall, an evaluation of the entire syst

subjected to impact loading shall be immediately removed from service and shall not be use

undamaged and suitable for reuse.

W

ERVICING

AINTENANCE: VI. M

this system. The company safety officer should maintain a record log of all servicing and inspection

dates for this unit. This unit a

subjected to fall arresting forc

B. CLEANING

Periodically clean the unit using a damp cloth and a non-abrasive mild soap or detergent. Towel dry.

C. STORAGE

Before storin

a

VII. WARNING LABELS:

Loading...

Loading...