OWNER’S

MANUAL

January 1996 Form: OM-222D

Effective With Serial No. KG054113

cover_om 4/95 − ST-800 168-B PRINTED IN USA

© 1996 MILLER Electric Mfg. Co.

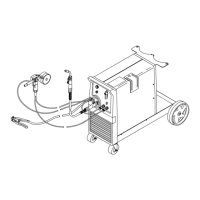

Gold Star® 302, 452, 652 (60 HZ)

Gold Star® 402, 602, 852 (50/60 HZ - )

CC/DC Welding Power Sources For SMAW, GTAW Welding, And CAC-A Cutting And Gouging

Model

Rated

Welding

Amp

Range

Maximum

Open-

Circuit

IP

Amperes Input at Rated Load Output, 50 or 60 Hz,

Three-Phase

Output

DC

Voltage

DC

a

ng

200 V 230 V 380 V 400 V 440 V 460 V 575 V KVA KW

300

Amp

300 A @

32 Volts

DC, 60%

Duty Cycle

15 − 395

72

(70)

21M __

61

3.6*

35

1.1*

33

1.1*

31

1.0*

31

3.1*

25

1.5*

24.5

1.3*

13.8

0.67*

450

Amp

450 A @

38 Volts

DC, 60%

Duty Cycle

20 − 590

72

(70)

21M

102

3.5*

89

3.1*

54

1.5*

51

1.4*

47

1.2*

45

1.5*

36

1.2*

35.5

1.2*

23.3

0.51*

650

Amp

650 A @

44 Volts

DC, 60%

Duty Cycle

50 − 850

72

(70)

21M −−

124

5.2*

75

1.7*

71

1.6*

65

1.5*

62

2.6*

50

2.1*

49.4

2.1*

36

0.58*

*While idling

( ) Indicates specification differences for CE models