Do you have a question about the Miller EnPak A30 GBW and is the answer not in the manual?

Explains hazard symbols and their meanings for safe operation.

Details hazards and precautions related to arc welding processes.

Safety advice for protecting eyes from flying debris during welding and related tasks.

Precautions for avoiding health hazards associated with welding fumes and gases.

Safety measures to prevent eye and skin burns from arc rays and sparks.

Warnings and precautions to prevent fires and explosions during welding operations.

Warning about potential hearing damage from noise and recommended protection.

Information on EMF interference with medical implants and precautions.

Safety guidelines for handling compressed gas cylinders to prevent explosions.

Details hazards associated with the engine, including battery, fuel, and moving parts.

Safety precautions and hazards related to the compressed air system.

Hazards and precautions for hot metal during cutting and gouging operations.

Safety warnings and procedures for working with compressed air systems.

Warning about the dangers of inhaling compressed air.

Safety precautions for trapped air pressure and whipping hoses.

Explains symbols related to installation, operation, and maintenance hazards.

Hazards and precautions related to battery charging and potential explosions.

Safety warnings regarding high-pressure fluids in the engine fuel system.

Safety advice for handling welding wire to prevent injury.

Warning about potential overheating due to excessive equipment use.

Precautions to prevent electrostatic discharge damage to electronic components.

Safety advice regarding trailer tilting and supporting the generator.

General instruction to read all labels and the manual before operating.

Information about high-frequency radiation interference and precautions.

Explanation of electromagnetic interference from arc welding and mitigation.

Warnings about chemical exposure from the product and diesel engines.

Lists key safety standards and where to obtain them for welding and related processes.

Details EMF information and procedures to minimize exposure from welding circuits.

Hazards related to gas accumulation and precautions.

Hazards of arc rays and protective measures.

Hazards and precautions for welding-induced fires and explosions.

Hazards and precautions for battery explosions.

Hazards and precautions for fuel-related fires and explosions.

Hazards related to moving parts and protective measures.

Hazards of exhaust sparks causing fires and prevention.

Hazards of hot parts and precautions to avoid burns.

Hazards from hot steam/coolant and precautions.

Critical warning about using generators indoors due to carbon monoxide.

Hazards of battery acid and first aid measures.

Hazards of engine heat causing fires and precautions.

Hazards of pneumatic equipment and safety procedures.

Hazards of hot metal from cutting/gouging and fire prevention.

Hazards of compressed air and safety precautions.

Hazards of inhaling compressed air.

Hazards of residual air pressure and whipping hoses.

Hazards from moving parts and protective measures.

Hazards related to fire or explosion and installation precautions.

Hazards from falling equipment and lifting safety.

Hazards of overheating electric motors and precautions.

Hazards of projected sparks and protective measures.

Warnings about chemical exposure from the product and diesel engines.

Lists key safety standards and where to obtain them for welding and related processes.

Explains additional safety symbols used in the manual for hazard identification.

Defines various symbols used for controls, specifications, and processes within the manual.

Locates the serial number and rating label for product identification.

Provides information on the End User License Agreement for third-party software.

Details specifications for the air compressor, including type, output, and pressure.

Outlines specifications for battery charging and crank assist functions.

Lists power ratings and engine details for the generator.

Provides output specifications for different welding modes like TIG, Stick, and MIG.

Details IP rating and temperature ranges for operating and storing the unit.

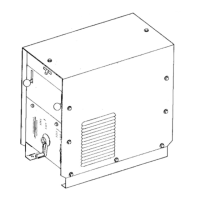

Provides physical dimensions, weight, and safe operating angle limits.

Lists dimensions and weights for various remote control panels.

Explains duty cycle percentages and overheating warnings for welding operations.

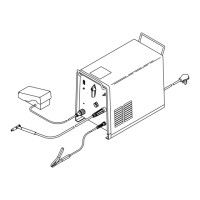

Instructions for mounting and securing the main unit, including clearance and bolting.

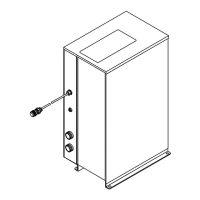

Step-by-step guide for mounting the remote control panel.

Instructions for installing the weld/battery charge remote panel.

Guide for installing the auxiliary power remote panel.

Details DC terminal strip connections for remote panels and vehicle power.

Instructions for connecting auxiliary power using the AC terminal strip.

Safety instructions for grounding the generator to vehicle frames.

Instructions for connecting the air compressor, including hose requirements.

Essential checks before starting the engine, including fluids and fuel.

Prestart checks for the air compressor, focusing on oil level and cleaner.

Guidance on installing the exhaust pipe, including safety positioning.

Instructions for connecting an external fuel supply to the unit.

Overview of the control panel layout and functions of various controls and indicators.

Explains the function of the process switch for selecting welding and charging modes.

Details how to access and navigate the service menu for settings and diagnostics.

Step-by-step instructions for updating the unit's software via USB.

Information on the summary file saved to USB, including firmware and error logs.

Explains the fuel gauge, hour meter, and engine shutdown indicators.

Details how the auto start/stop feature works for engine and compressor based on load.

Instructions for operating the air compressor switch and adjusting air pressure.

Explains compressor controls, pressure settings, and auto start/stop functions.

Guidance on operating the compressor with air tools and required air tank size.

How to use chassis power and its interaction with auto start/stop features.

General guidelines and safety precautions for charging vehicle batteries.

Steps for connecting an external battery for charging.

Instructions for connecting a battery already installed in a vehicle.

How to set battery charge controls for different voltages and functions.

How to set controls for battery jump-start and crank assist functions.

Explains display messages and codes related to battery charging status.

Information on generator receptacles and protective devices for auxiliary equipment.

Details GFCI receptacle functions, testing, and resetting procedures.

Instructions for wiring a 240V plug for auxiliary power connections.

Guide for selecting appropriate weld cable sizes based on length and amperage.

Identifies weld output terminals and connection requirements.

Overview of controls used for welding operations, including switches and buttons.

Explains arc control settings for different welding processes and their effects.

Procedure for starting a stick welding arc using the scratch start method.

Instructions for Lift-Arc TIG start and Auto-Stop feature for ending the arc.

Guide for connecting MIG welding equipment and typical settings.

Instructions for connecting a spool gun accessory for welding.

Information on connecting to the CAN-bus for data communication.

Lists J1939 messages and their meanings for engine and compressor data.

Explains the maintenance schedule and labels found on the unit.

Outlines routine maintenance tasks and their recommended intervals.

Detailed steps for changing compressor oil, filter, and air cleaner.

Instructions for cleaning and replacing the engine air cleaner element.

Steps for changing engine oil, oil filter, and fuel filter.

Information on overload protection devices like circuit breakers and fuses.

Explains error codes displayed on the voltmeter/ammeter and their remedies.

Troubleshooting guide for common compressor issues and their solutions.

Lists recommended spare parts for maintenance and common replacements.

Provides the first part of the electrical circuit diagram for the welder/generator.

Provides the second part of the electrical circuit diagram for the welder/generator.

Illustrates the air compressor system schematic with its components.

Guidance on selecting appropriate equipment and understanding electrical connections.

Safety instructions for grounding the generator to vehicle frames.

Procedures for grounding the generator when supplying building electrical systems.

Explains how to calculate power requirements for various equipment.

Table showing approximate power requirements for different industrial motors.

Table showing approximate power requirements for farm and home equipment.

Table showing approximate power requirements for contractor equipment.

Explains how to determine starting power requirements for single-phase induction motors.

Guidance on generator output limits and starting non-resistive loads.

Illustrates typical connections for supplying standby power from the generator.

Charts for selecting appropriate extension cords based on current, load, and length.

Details the terms and conditions of the limited warranty for EnPak equipment.

| Model | EnPak A30 GBW |

|---|---|

| Type | Welding System |

| Output Current Range | 5-300 A |

| Fuel Type | Gasoline |

| Frequency | 60 Hz |

| Power Factor | 0.8 |

| Protection Class | IP23 |

| Output Voltage Range | 10-32 V |

| Welding Processes | Stick |

| Air Compressor | 30 CFM @ 100 PSI |

| Input Voltage | Not applicable |

| Input Current | Not applicable |

Loading...

Loading...