Do you have a question about the Miller DIALARC HF and is the answer not in the manual?

Details the manufacturer's warranty for equipment, including duration and limitations.

List and descriptions of various optional accessories available for the welding equipment.

Certification statement regarding type-testing for high-frequency stabilized arc welding equipment.

Section for the user to certify the proper installation and use of the welding equipment.

Learn safety through personal experience and understanding of safe practices.

Covers burn prevention, toxic fume prevention, fire/explosion prevention, compressed gas, user responsibilities, and equipment handling.

Safety precautions specific to arc welding, including burn protection, toxic fumes, fire, explosion, and shock prevention.

List of relevant safety standards and their sources for further information.

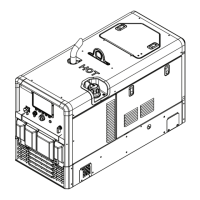

Overview of the manual's purpose: familiarizing personnel with equipment design, installation, operation, and maintenance.

Instructions for inspecting equipment upon receipt and handling claims for transit damage.

Details the unit as a single-phase welding power source for Stick and TIG welding.

Emphasizes reading the safety section completely before operation to avoid injury.

Guidelines for selecting a proper installation site ensuring adequate airflow and accessibility.

Information on making safe and proper electrical input connections, including disconnect switch recommendations.

Recommendations for selecting and using appropriate welding cables and connectors for optimal performance.

Instructions for connecting a remote amperage control to the welding power source circuitry.

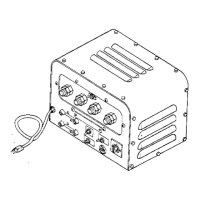

Describes the function of the power switch for energizing or shutting down the welding power source.

Explains how the range selector switch adjusts coarse amperage settings across three ranges.

Details the front panel control for fine-tuning amperage output within a selected range.

Covers the receptacle and switch for using or bypassing a remote amperage control.

Protects the control circuit components; tripping indicates a short or internal problem.

Allows selection of AC, DC straight, or DC reverse polarity without changing cable connections.

Connect remote controls and select high-frequency operation modes.

Adjust post-flow time and utilize the 115V AC receptacle for accessories.

Explains how duty cycle is rated and how to determine safe output at various duty cycles.

Illustrates output voltage versus current, helping to determine amperage for specific load voltages.

Step-by-step procedure for performing shielded metal-arc (stick electrode) welding.

Step-by-step procedure for performing gas tungsten-arc (TIG) welding.

Procedure for safely shutting down the welding power source after operation.

Information on the fan motor, noting its lifetime lubrication and low maintenance requirements.

Recommendation for periodic cleaning of the transformer by blowing out dust and dirt.

Guidance on occasional cleaning of the rectifier using compressed air for optimal cooling.

Instructions for inspecting and adjusting spark gap settings for proper high-frequency output.

Troubleshooting no welding current, low current, erratic current, and control breaker trips.

Addresses issues with fan motor, amperage control, and thermostat faults.

Resolving arc wander, tungsten oxidation, and high-frequency initiation difficulties.

Importance of proper installation and certification for FCC compliance and minimizing interference.

Details how interfering radiation escapes and the importance of shielding and grounding.

Specific instructions for primary power service connections, emphasizing shielded conduit and grounding.

Guidelines for grounding the welding machine and ensuring good electrical contact for installation.

Recommendations for minimizing radiation by keeping welding leads short and properly positioned.

Strategies to minimize interference from wiring near the welding area, focusing on shielding and grounding.

Specifications for proper ground connections to reduce interference, including driven rods and water pipes.

Considerations for operating in metal buildings, emphasizing the need for proper grounding and installation requirements.

User's option to conduct individual field surveys and certify the installation based on compliance.

A comprehensive checklist for installers to verify that all installation requirements have been met.

| Brand | Miller |

|---|---|

| Model | DIALARC HF |

| Category | Welding System |

| Language | English |