Processes

OM-263920B 2018-05

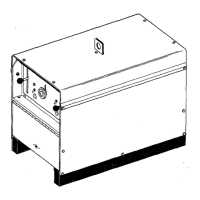

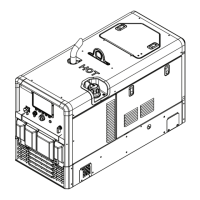

DIVERSIONt180 w/Auto-Linet

Processes

TIG (GTAW) Welding

Description

Diversion 180: 115-230 VAC Arc Weld-

ing Power Source w/Auto-Linet

File: TIG (GTAW)

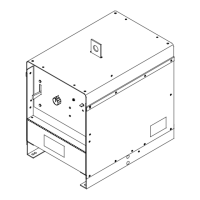

Diversion 165: 230 Volt Arc Welding

Power Source

DIVERSIONt165 And

Scan this tag with your mobile device

to learn more about this product.

Individual carrier rates may apply.

Start by downloading the free mobile

app at http://gettag.mobi

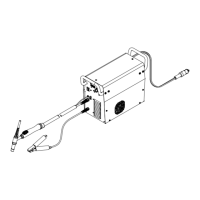

(WP−17 Torch)

For product information,

Owner’s Manual translations,

and more, visit

www.MillerWelds.com