Do you have a question about the Miller Bobcat 200 Air Pak Diesel and is the answer not in the manual?

| Welding Output | DC |

|---|---|

| Voltage Output | 120/240 V |

| TIG Capability | Yes |

| MIG Capability | Yes |

| Rated Output | 200 A at 25 V |

| Fuel Tank Capacity | 12.5 gallons |

| Phase | Single |

| Stick Electrode Capacity | Up to 5/32 in |

Details hazards associated with arc welding processes and electrical safety.

Covers potential dangers related to the engine, including fuel, moving parts, and batteries.

Outlines risks associated with compressed air systems and equipment.

French section detailing risks associated with arc welding.

French section covering engine-related hazards and warnings.

French section detailing hazards related to compressed air.

Information on chemicals known to cause cancer or birth defects.

Lists key safety standards and their sources for reference.

Explains electromagnetic fields and potential interference with medical implants.

Explains additional warning symbols used in the manual.

Defines various symbols used for technical specifications and functions.

Details the performance and capacity of the air compressor system.

Provides specifications for the battery charging and jump-start functions.

Lists generator power ratings and engine details.

Outlines welding output capabilities for different modes and duty cycles.

Instructions for proper placement, mounting, and airflow clearance of the unit.

Guidance on safely grounding the generator to a vehicle frame.

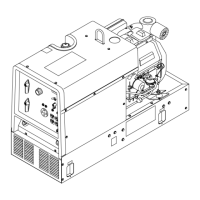

Identifies and explains the function of controls and indicators on the main panel.

Further details on control panel functions, engine gauges, and indicator lights.

Explains how to select welding processes and battery charging modes.

Details how to operate the air compressor switch and adjust air pressure settings.

Explains the functions of various air compressor controls and sensors.

Provides essential guidelines and precautions for safe battery charging.

Steps for connecting an external battery for charging or jump-starting.

Instructions for connecting a battery already installed in a vehicle.

Describes the generator outlets and their protective circuit breakers.

Explains GFCI receptacle function, testing procedures, and troubleshooting.

Guide for choosing appropriate weld cable sizes based on amperage and length.

Identifies the positive and negative weld output terminals.

Step-by-step instructions for correctly connecting welding output cables.

Explains the function of weld controls like Charge/Weld switch and Process switch.

Overview of the maintenance schedule and intervals for the unit.

Lists regular maintenance tasks and their recommended frequency.

Detailed steps for replacing key compressor service components.

Procedure for replacing the engine's air cleaner element.

Instructions for changing engine oil, filters, and fuel filter.

Steps for draining and refilling the engine's cooling system.

Explains the function of supplementary protectors and fuses for overload safety.

Lists error codes displayed on the voltmeter/ammeter and their remedies.

Specific troubleshooting steps for air compressor problems.

Troubleshooting steps for engine-related issues and starting problems.

List of recommended spare parts for common maintenance needs.

Electrical schematic showing connections for the welder/generator system.

Detailed schematic illustrating the air compressor system components and flow.

Guidance on choosing appropriate electrical equipment for use with the generator.

Instructions for safely grounding the generator when mounted on a vehicle.

Procedures for grounding the generator when connecting to building electrical systems.

Explains how to calculate power requirements for various equipment.

Table to help select the correct extension cord gauge based on load and length.

Loading...

Loading...