Do you have a question about the Miller Bobcat 265X and is the answer not in the manual?

Explains the meaning of safety symbols used throughout the manual.

Details hazards associated with arc welding processes and protective measures.

Outlines potential dangers related to the engine and its components.

Covers hazards related to compressed air equipment and its use.

Addresses further hazards during installation, operation, and maintenance.

Provides chemical exposure warnings as required by California law.

Lists key safety standards and their sources for reference.

Explains electromagnetic field effects and precautions for users.

Defines additional safety symbols, potentially for specific product versions.

Provides definitions for miscellaneous symbols used in the manual.

Details the location of serial and rating labels for product identification.

Outlines the end-user license agreement for included software.

Discusses default weld parameters and the need for user evaluation.

Lists detailed specifications for welding output, power, and engine.

Details IP rating and temperature specifications for operation and storage.

Specifies the Ingress Protection (IP) rating of the equipment.

Details operating and storage temperature ranges for the unit.

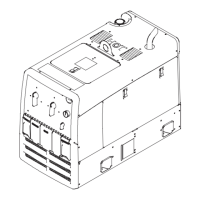

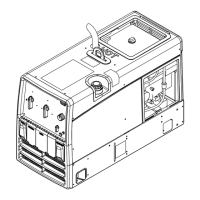

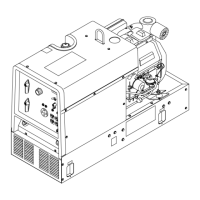

Provides physical dimensions, weight, and operating angle limits of the unit.

Lists dimensions for units equipped with optional running gear.

Explains duty cycle ratings and the risks of overheating the unit.

Shows output capabilities of the welding generator across different amperage settings.

Details fuel usage rates for auxiliary power and welding loads.

Provides instructions and safety precautions for mounting and positioning the unit.

Details how to properly ground the generator frame to a vehicle frame.

Guides on routing the ground cable securely and correctly.

Instructions for installing the exhaust pipe, including safety considerations.

Outlines necessary checks for the engine before starting it.

Explains the correct procedure for connecting or replacing the unit's battery.

Identifies and describes the weld output terminals on the unit.

Details the correct method for connecting weld output cables to terminals.

Provides guidelines for selecting appropriate weld cable sizes based on current and length.

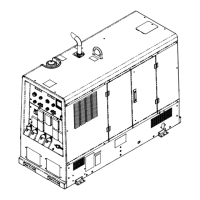

Describes the function of each control on the front panel of the unit.

Explains the fuel gauge, hour meter, and oil change indicators.

Provides typical connections and settings for Stick (SMAW) welding.

Details typical connections and settings for MIG (GMAW) welding.

Covers setup and parameters for solid wire MIG welding applications.

Details setup and parameters for self-shielded flux core MIG welding.

Offers guidance on operating the engine in cold weather conditions.

Identifies and describes the available generator power receptacles.

Explains GFCI receptacle functions, testing, and resetting procedures.

Discusses power output distribution when welding and using auxiliary power.

Provides instructions for wiring a 240V, single-phase NEMA 14-50P plug.

Provides instructions for wiring a 240V, single-phase NEMA 6-50P plug.

Presents a maintenance schedule for regular checks and servicing.

Details the information found on the machine's maintenance label.

Provides instructions for cleaning or replacing the air cleaner element.

Explains the overload protection system, including fuse F6.

Details the procedure for changing engine oil, oil filter, and fuel filter.

Guides on adjusting engine idle and weld/power speeds.

Instructions for cleaning and inspecting the optional spark arrestor.

Explains the meaning of the fault indicator light and its possible causes.

A comprehensive guide to diagnosing and resolving welding and generator issues.

Guides on diagnosing and resolving welding-related problems.

Guides on diagnosing and resolving generator power output issues.

Guides on diagnosing and resolving engine-related problems.

Lists recommended spare parts with their part numbers and descriptions.

Presents the main electrical circuit diagram for the unit.

Advises on selecting suitable electrical equipment to connect to the generator.

Explains grounding procedures when supplying power to building systems.

Helps users determine the power requirements of their equipment.

Provides power requirements for various industrial motors.

Lists approximate power needs for farm and shop equipment.

Details power requirements for common contractor equipment.

Explains how to calculate the power needed for starting motors.

Guides on how to manage loads to not exceed the generator's capacity.

Illustrates typical connections for using the generator with standby power systems.

Provides tables for selecting appropriate extension cords based on length and load.

Offers guidance on selecting extension cord lengths for 120V loads.

Offers guidance on selecting extension cord lengths for 240V loads.

Outlines the basic steps and tools needed for stick welding.

Helps select the correct electrode and amperage for different welding tasks.

Describes methods for initiating the welding arc (scratch and tapping).

Explains correct electrode positioning for groove and fillet welds.

Illustrates common problems with weld beads and their causes.

Shows examples of good weld beads and characteristics to aim for.

Details how electrode angle, arc length, and travel speed affect weld bead shape.

Describes stringer and weave bead techniques for different weld joints.

Illustrates techniques for welding lap joints.

Explains methods for welding groove (butt) joints, including preparation.

Illustrates techniques for welding T-joints.

Describes how to perform a weld test to check for quality and diagnose issues.

Guides on troubleshooting common welding issues like porosity and penetration.

Shows typical connections for MIG welding using a voltage-sensing wire feeder.

Details proper techniques for holding and positioning the welding gun.

Explains how gun angle, distance, and speed affect MIG weld bead shape.

Describes stringer and weave bead techniques for MIG welding.

Illustrates common poor weld bead characteristics in MIG welding.

Shows examples of good weld bead characteristics in MIG welding.

Guides on resolving excessive spatter issues in MIG welding.

Helps diagnose and fix porosity problems in MIG welds.

Guides on resolving excessive penetration issues in MIG welding.

Helps diagnose and fix lack of penetration problems in MIG welds.

Guides on resolving incomplete fusion issues in MIG welding.

Helps diagnose and fix burn-through issues in MIG welding.

Guides on resolving wavy bead issues in MIG welding.

Helps diagnose and fix distortion problems in MIG welding.

A chart listing common MIG shielding gases and their applications.

A guide to troubleshooting wire feed and arc stability issues in MIG welding.

| Rated Output | 9, 500 Watts |

|---|---|

| Fuel Type | Gasoline |

| Type | Engine-Driven Welder/Generator |

| Open Circuit Voltage | 80 VDC |

| AC Output | 120/240V |

| Voltage Output | 120/240 VAC |

| Engine | Kohler |