Do you have a question about the Miller Bobcat 200 Air Pak and is the answer not in the manual?

Explains the meaning of symbols used in the manual to indicate hazards and warnings.

Details potential hazards associated with arc welding, including electric shock and proper procedures.

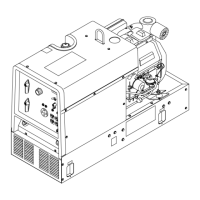

Covers hazards related to the engine, such as battery explosion, fuel risks, and moving parts.

Highlights dangers associated with compressed air equipment, including injury and death risks.

Defines symbols related to fire, explosion, falling equipment, and overheating hazards.

Provides warnings about chemical exposures from the product and diesel engines.

Lists relevant industry safety standards and where to obtain them.

Explains electromagnetic fields (EMF) and their potential interference with medical implants.

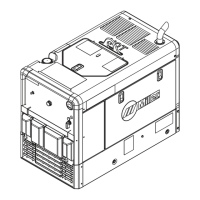

Identifies the location of the product's serial and rating information.

Details the performance and capacity of the air compressor.

Outlines the output and voltage capabilities of the battery charger.

Provides details on generator power rating, fuel capacity, and engine type.

Lists rated welding output and voltage ranges for different welding modes.

Specifies the IP rating and intended use environment for the equipment.

Defines the operating and storage temperature ranges for the unit.

Provides physical measurements, weight, and tilt angle limitations.

Explains duty cycle percentages at different amperages and overheating precautions.

Illustrates generator power output in amperes for 120V and 240V loads.

Shows minimum and maximum voltage/amperage capabilities for welding processes.

Displays voltage and amperage curves for battery charging operations.

Provides graphs showing fuel consumption for air compressor, auxiliary power, and welding.

Provides guidance on unit placement, movement, and airflow clearance requirements.

Details the procedure for grounding the generator frame to a vehicle frame for safety.

Explains how to connect the air compressor, including hose requirements and fittings.

Outlines essential checks for the engine before starting, including fluids and fuel.

Details pre-operation checks for the compressor, focusing on oil level and air cleaner.

Provides instructions for correctly connecting the unit's battery.

Guides on installing the exhaust pipe, including proper direction and clamping.

Explains how to connect an external fuel supply, including hose routing and filling.

Identifies and describes the main components and indicators on the control panel.

Provides further descriptions of control panel functions and indicators.

Explains the function of the process switch for selecting welding or battery charge modes.

Details how to access and navigate the service menu for settings and diagnostics.

Provides instructions on how to update the unit's software using a USB drive.

Explains how to access and interpret the summary file for diagnostic information.

Describes the function and display of the fuel gauge and hour meter.

Explains the function of the compressor switch for selecting CFM output and operation modes.

Details the controls for adjusting system pressure and the compressor's idle/standby modes.

Provides guidance on operating the air compressor with various air tools.

Lists important guidelines and precautions for charging and jump-starting batteries.

Provides step-by-step instructions for connecting an external battery for charging.

Details how to connect a vehicle's installed battery for charging or jump-starting.

Explains how to set the controls for battery charging operations.

Details how to set controls for jump-starting or crank-assisting a vehicle.

Explains the information displayed on the screens during battery charging.

Identifies the power receptacles and supplementary protectors on the generator.

Provides information on GFCI receptacles, including testing and resetting procedures.

Details wiring instructions for the optional 240 Volt, single-phase plug (NEMA 14-50P).

Provides a chart for selecting appropriate weld cable sizes based on length and duty cycle.

Identifies the positive and negative weld output terminals on the machine.

Explains the correct procedure for connecting weld output cables to the terminals.

Identifies the main controls used for welding operations.

Details arc control settings for different welding processes and their effects.

Describes the scratch start technique for initiating a welding arc with stick electrodes.

Explains the Lift-Arc TIG process for starting an arc and using Auto-Stop.

Provides guidelines for MIG welding connections, settings, and gas requirements.

Details the connections required for using a spool gun accessory.

Provides a maintenance schedule based on operating hours and time intervals.

Outlines regular maintenance activities like checking fluids, filters, and belts.

Details the process for changing compressor oil, oil filter, and air cleaner element.

Explains how to clean and service the air cleaner element and pre-cleaner.

Provides instructions for changing engine oil, oil filter, and fuel filter.

Describes the overload protection devices (circuit breakers, protectors) and their function.

Lists common error displays and their descriptions, remedies, and troubleshooting steps.

Provides solutions for common problems related to the air compressor's operation.

Lists part numbers and descriptions for recommended spare parts.

Guidance on selecting appropriate equipment to connect to the generator.

Details on grounding the generator frame to a vehicle for electrical safety.

Instructions for grounding the generator when supplying power to building systems.

Explains how to calculate power needs for various equipment using volts and amperes.

Provides approximate power requirements for different types and sizes of industrial motors.

Lists approximate power requirements for common farm and home equipment.

Provides approximate power requirements for various contractor tools and equipment.

Details the starting amperage requirements for single-phase induction motors.

Explains how to determine the generator's power supply capacity and load management.

Illustrates typical connections for supplying standby power during outages.

Guides on selecting appropriate extension cords based on load, length, and conductor size.

| Engine Power | 23 HP |

|---|---|

| Fuel Tank Capacity | 12 Gallons |

| Engine Type | Kohler Command Pro |

| Open-Circuit Voltage (OCV) | 80 Volts |

| Engine | Kohler CH740 |

| AC Generator Output | 120/240 Volts |

| Auxiliary Power | 7, 000 Watts Continuous |