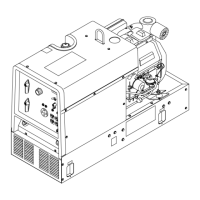

What to do if Miller Bobcat 3 Phase has low or no weld output but generator power is okay?

- CCharles ColonJul 28, 2025

If your Miller Welding System shows low or no weld output while the generator power output at AC receptacles is fine, consider the following: * Check the control settings. * Verify the weld connections. * Inspect fuse F1 and replace it if it's open.