OM-4436 Page 52

SECTION 14 − MIG WELDING (GMAW) GUIDELINES

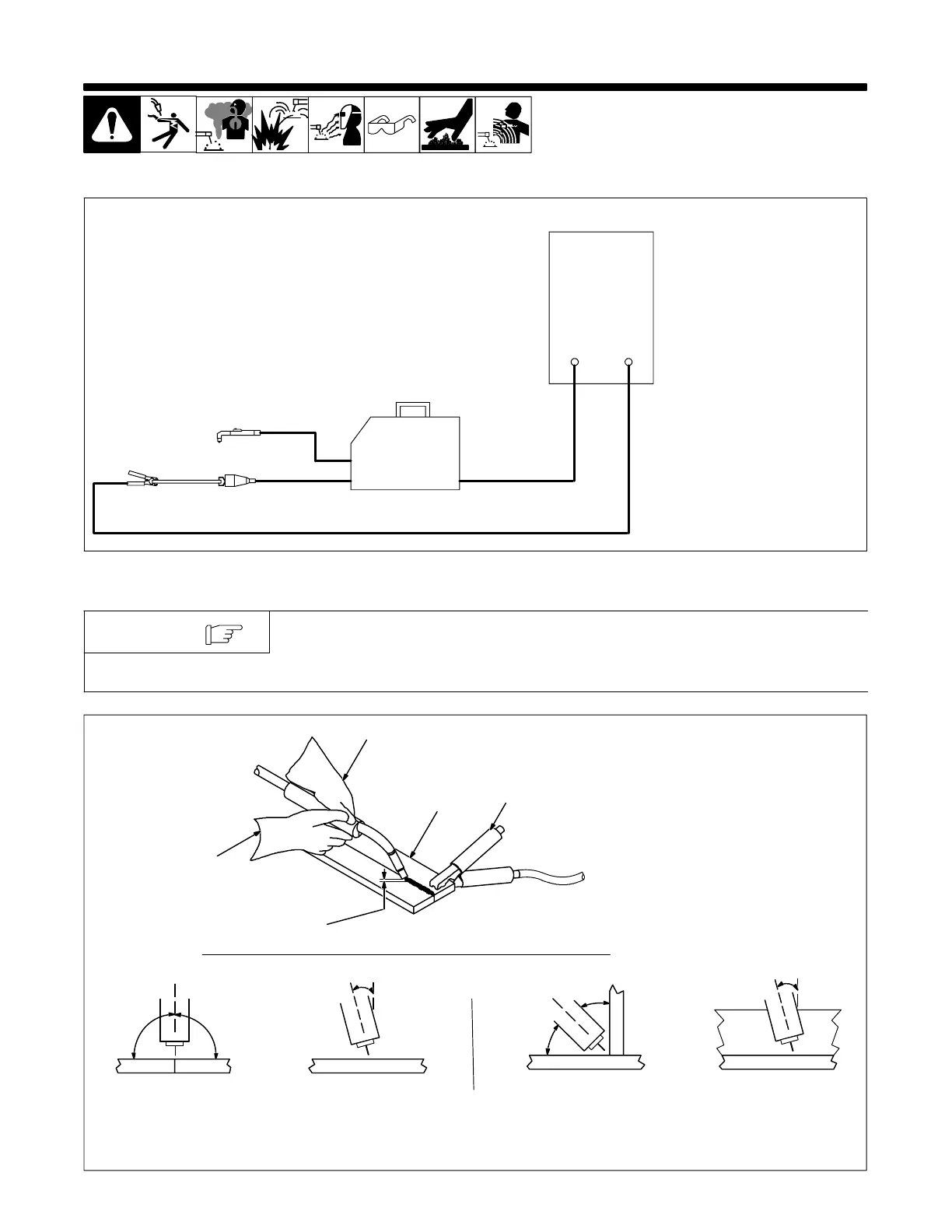

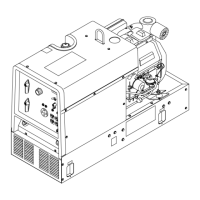

14-1. Typical MIG Process Connections Using A Voltage-Sensing Wire Feeder

Weld current can damage

electronic parts in vehicles.

Disconnect both battery

cables before welding on a

vehicle. Place work clamp as

close to the weld as possible.

Voltage sensing wire feeders are

used with constant current (CC) or

constant voltage (CV) power

sources (14 pin receptacle not re-

quired).

If using a CC or CV welding power

source without a weld output con-

tactor, use optional secondary con-

tactor.

For GMAW, use optional gas valve.

Voltage

Sensing Wire

Feeder

Constant

Current (CC)

Or Constant

Voltage (CV)

Power Source

Work Lead

Electrode Lead

Workpiece

Work Clamp Voltage

Sensing Clamp

Gun

802 488

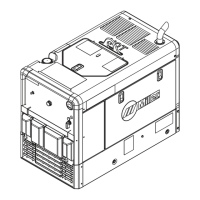

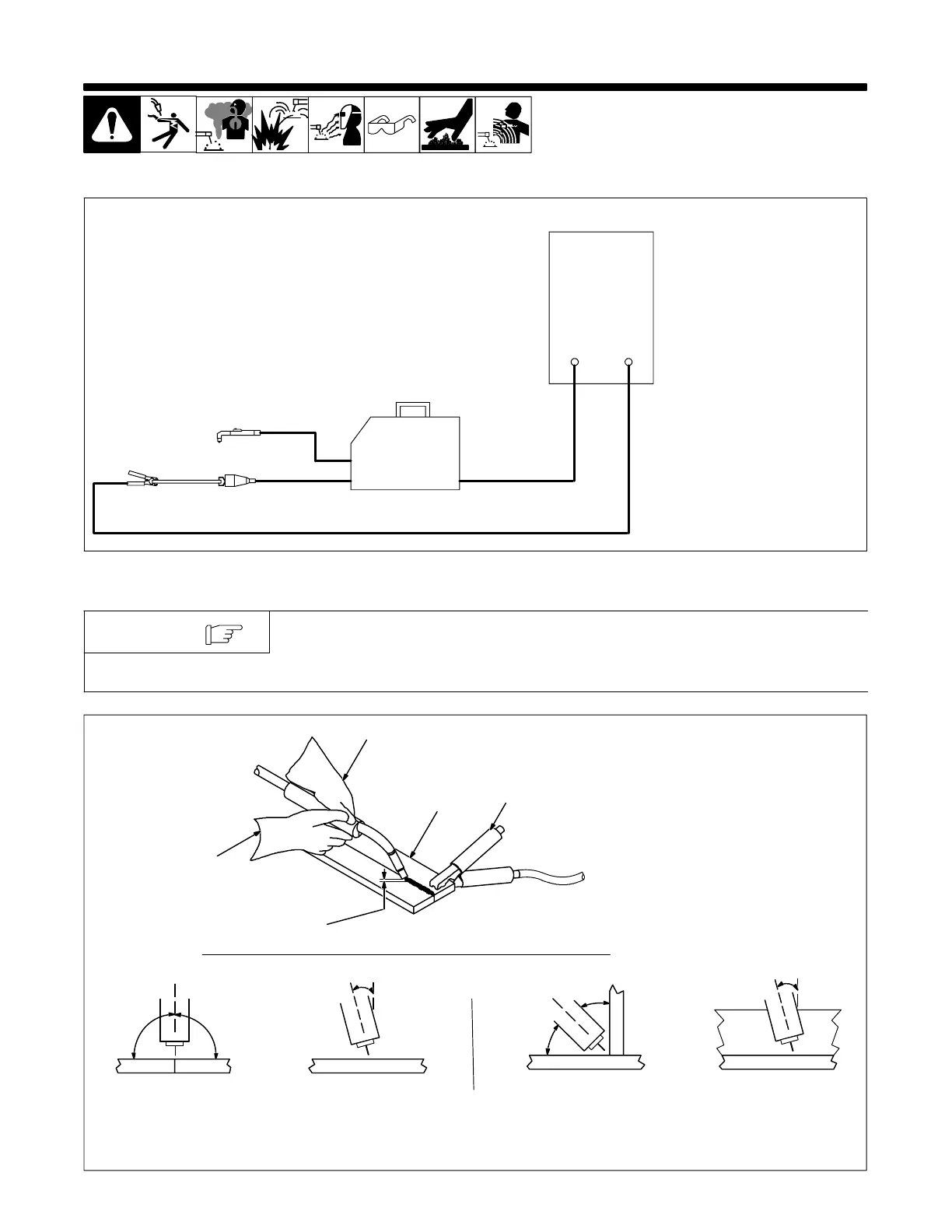

14-2. Holding And Positioning Welding Gun

Welding wire is energized when gun trigger is pressed. Before lowering helmet and

pressing trigger, be sure wire is no more than 1/2 in (13 mm) past end of nozzle,

and tip of wire is positioned correctly on seam.

NOTE

1 Hold Gun and Control Gun

Trigger

2 Workpiece

3 Work Clamp

4 Electrode Extension (Stickout)

1/4 to 1/2 in (6 To 13 mm)

5 Cradle Gun and Rest Hand on

Workpiece

2

3

5

4

90° 90°

0°-15°

45°

45°

GROOVE WELDS

FILLET WELDS

End View Of Work Angle Side View Of Gun Angle

End View Of Work Angle Side View Of Gun Angle

1

0°-15°

S-0421-A

Loading...

Loading...