Do you have a question about the Miller Bobcat 260 and is the answer not in the manual?

Details Miller's Trueblue warranty program and its exclusive nature.

Highlights Miller's commitment to quality, noted by ISO 9001 registration.

Explains safety symbols used in the manual to indicate hazards and instructions.

Details hazards associated with arc welding processes, including electrical shock and burns.

Fatal hazard of carbon monoxide poisoning from indoor generator use.

Risks associated with battery handling, including explosion from gases and acid.

Hazards from improper installation or operation of compressed air equipment.

General hazards for installation, operation, maintenance, fire, explosion, and falling equipment.

Warnings about chemical exposure from the product and diesel engine exhaust.

List of key safety standards and their sources.

Explains safety symbols found on CE products and other miscellaneous symbols.

Locating serial numbers, rating labels, and software licensing agreement.

Technical specs for welding and power output with CH730 and ECH730 engines.

Specifies operating temperatures and FCC approval for the wireless remote.

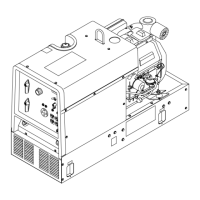

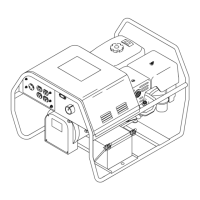

Guidance on proper installation, mounting, and airflow clearance for the unit.

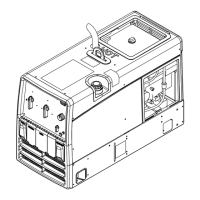

Overview of the front panel controls, including engine start, process selection, and settings.

Description of the generator power receptacles and their output capabilities.

Schedule of routine maintenance tasks based on operating hours.

List of recommended spare parts for the welder/generator, including part numbers.

Provides a detailed circuit diagram for the gasoline-powered welder/generator.

Guidance on selecting equipment and grounding the generator to a vehicle frame.

Recommended connections, settings, and procedures for stick welding.

Connecting MIG welding equipment with a voltage-sensing feeder.

Details the terms and conditions of Miller's limited warranty for its equipment.

Provides contact information for warranty inquiries and distributor support.

Instructions on how to contact distributors or service agencies for support.

| Brand | Miller |

|---|---|

| Model | Bobcat 260 |

| Category | Welding System |

| Language | English |