OM-286504 Page 63

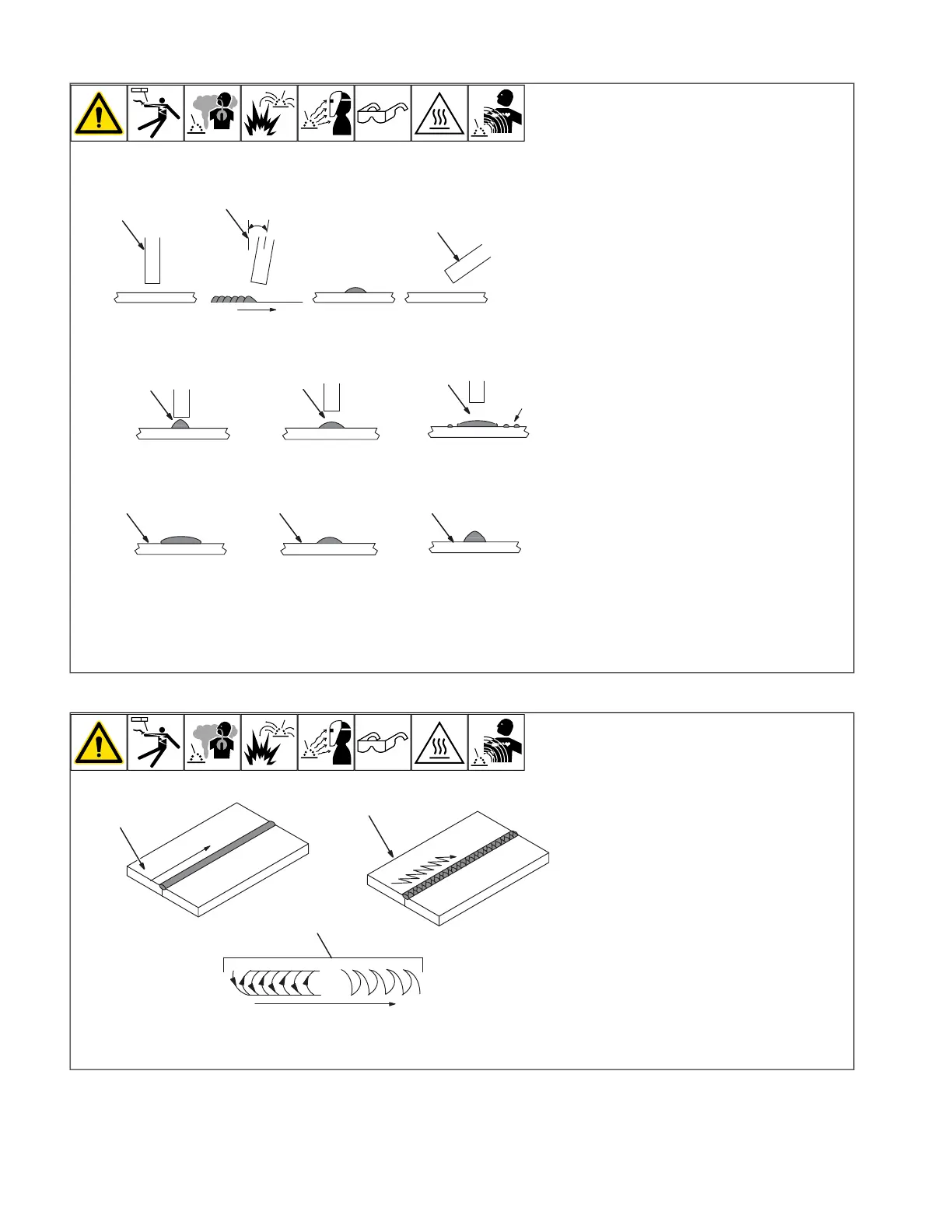

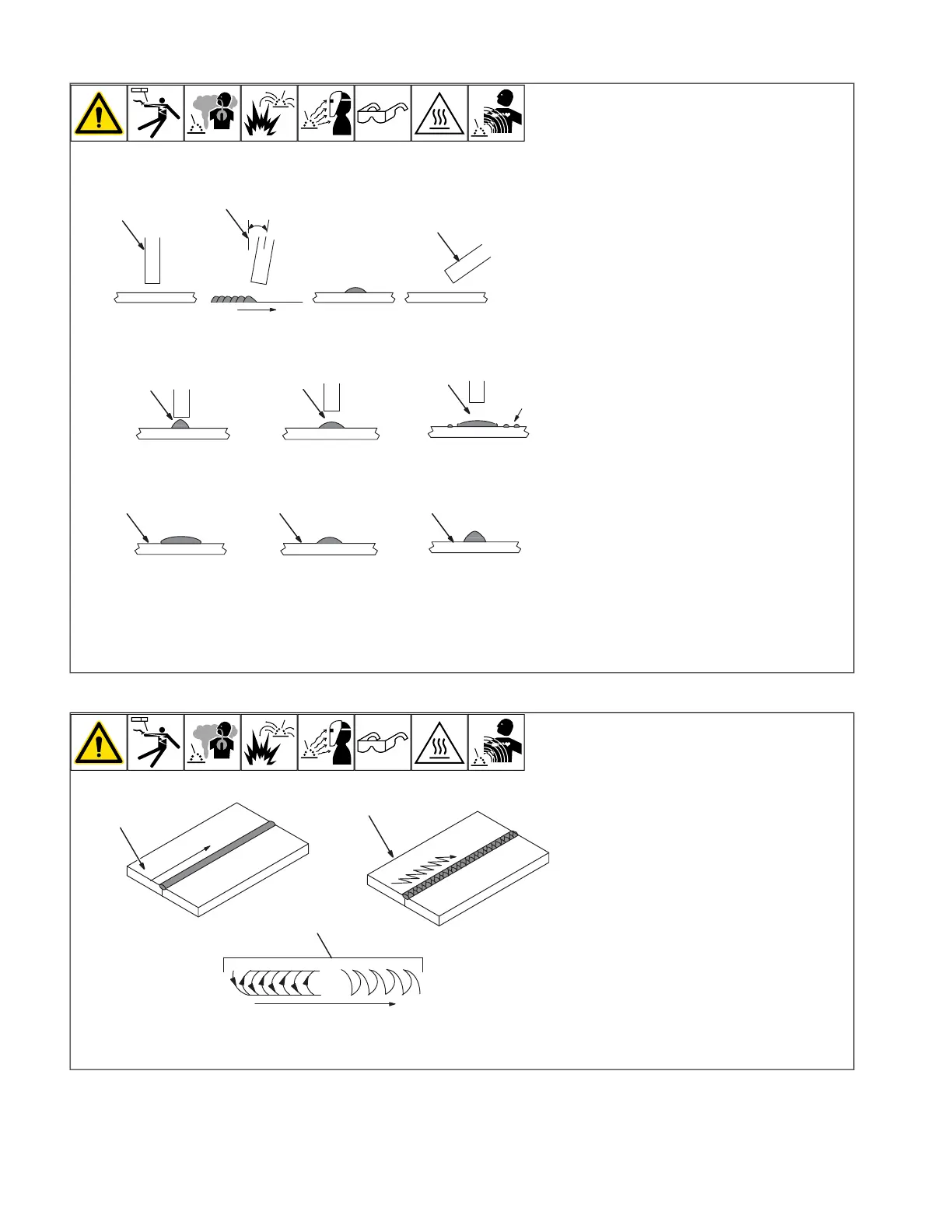

12-7. Conditions That Affect Weld Bead Shape

Electrode Angle

OM-

10

° -

30

°

1

2

3

4

5

6

7

8

9

10

11

Arc Length

Travel Speed

F

Weld bead shape is affected by elec-

trode angle, arc length, travel speed,

and thickness of base metal.

1 Angle Too Small

2 Correct Angle

3 Drag

4 Angle Too Large

5 Too Short

6 Normal

7 Too Long

8 Spatter

9 Slow

10 Normal

11 Fast

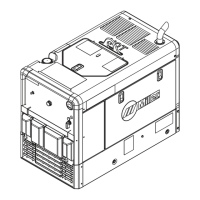

12-8. Electrode Movement During Welding

OM-4419 Page 1

3

1

2

5

4

2

3

1

2

3

1

4

5

F

Normally, a single stringer bead is sat-

isfactory for most narrow groove weld

joints; however, for wide groove weld

joints or bridging across gaps, a weave

bead or multiple stringer beads works

better.

1 Stringer Bead - Steady Movement Along

Seam

2 Weave Bead - Side To Side Movement

Along Seam

3 Weave Patterns

Use weave patterns to cover a wide area in

one pass of the electrode. Do not let weave

width exceed 2-1/2 times diameter of

electrode.

Loading...

Loading...