OM-286504 Page 26

F

Complete Parts List is available at www.MillerWelds.com

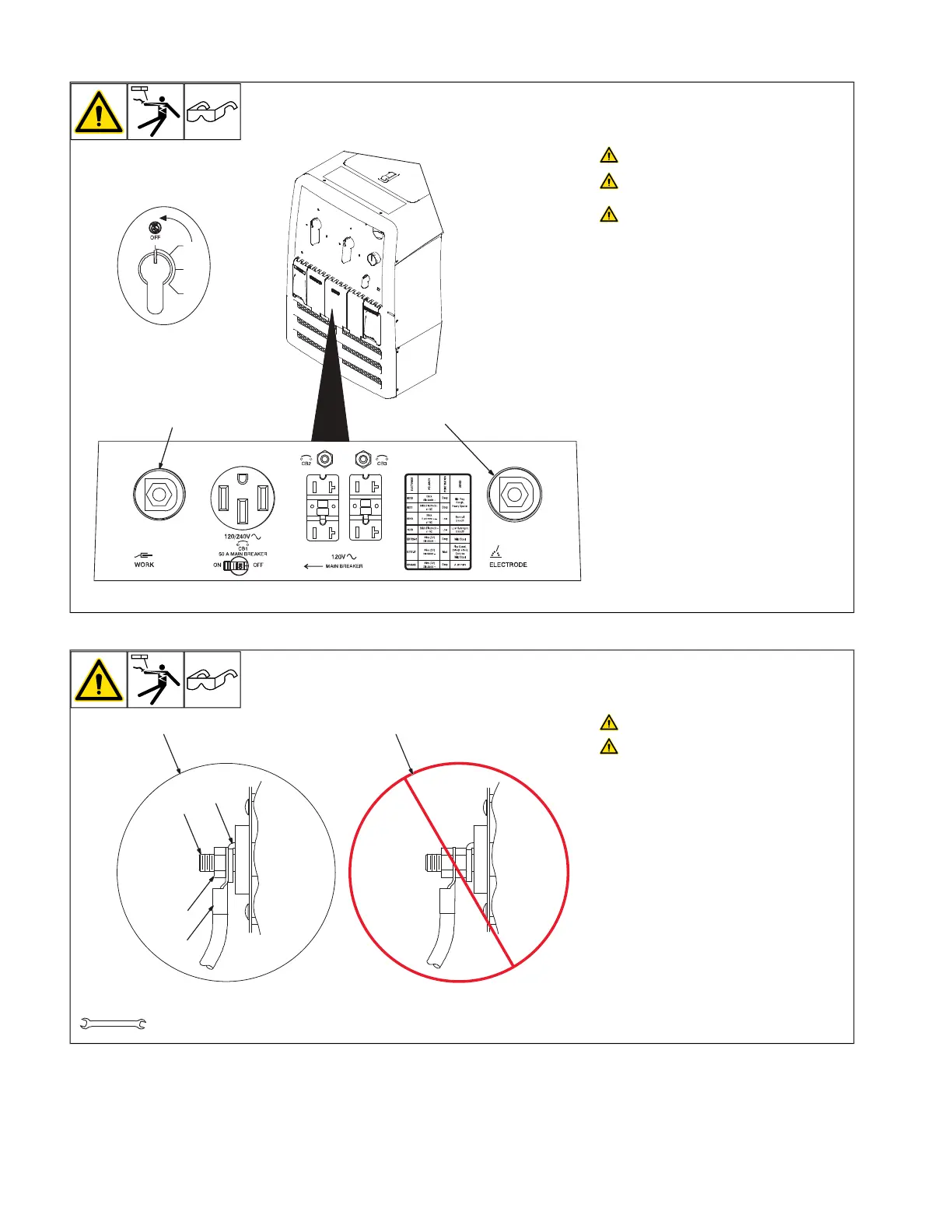

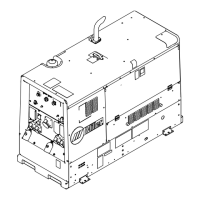

5-7. Weld Output Terminals

Complete Parts List available at www.MillerWelds.com

OM-249336 Page 8

250916-A / 250290-A

1

2

Stop engine.

Turn off power before connecting

to weld output terminals.

Do not use worn, damaged, under-

sized, or repaired cables.

1 Work Weld Output Terminal

2 Electrode Weld Output Terminal

Connect work cable to Work terminal.

Connect electrode holder cable or electrode

weld cable to Electrode terminal for Stick

and MIG welding.

Connect torch cable to Electrode terminal for

TIG welding.

Use Process Selector switch to select type

of weld output (see Section 6-1).

F

See Sections 6-4 thru 6-6 for typical

process connections and control

settings.

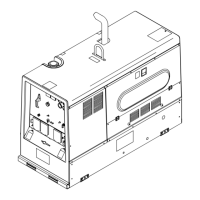

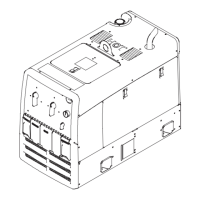

5-8. Connecting Weld Output Cables

Complete Parts List available at www.MillerWelds.com

OM-249336 Page 26

4

2

3

1

5

6

OM-222 Page 1

allen_wrench

NGO’s

tools/

flathead philips head wrench

pliers

knife

heavy-duty workclamp light-duty workclamp wirecutter frontcutter

allen_set

needlenose

steelbrush nutdriver

chippinghammer

solderiron

stripcrimp

drill

torque wrench

socket wrench

hammer awl file

crimper

paintbrush

feelergauge flashlight ruler

toothbrush

greasegun

qtip (swab)

vicegrip

handream

punch

filterwrench

strapwrench

airgun

solvent pinextractor eprompuller pipewrench

torque screwdriver

crescent wrench

3/4 in. (19 mm)

Stop engine.

Failure to properly connect weld

cables may cause excessive heat

and start a fire, or damage your

machine.

F

Do not place anything between weld

cable terminal and copper bar. Make

sure that the surfaces of the weld cable

terminal and copper bar are clean.

1 Correct Weld Cable Connection

2 Incorrect Weld Cable Connection

3 Weld Output Terminal

4 Supplied Weld Output Terminal Nut

5 Weld Cable Terminal

6 Copper Bar

Remove supplied nut from weld output termi-

nal. Slide weld cable terminal onto weld out-

put terminal and secure with nut so that weld

cable terminal is tight against copper bar.

Loading...

Loading...