OM-286504 Page 28

F

Complete Parts List is available at www.MillerWelds.com

SECTION 6 – OPERATION

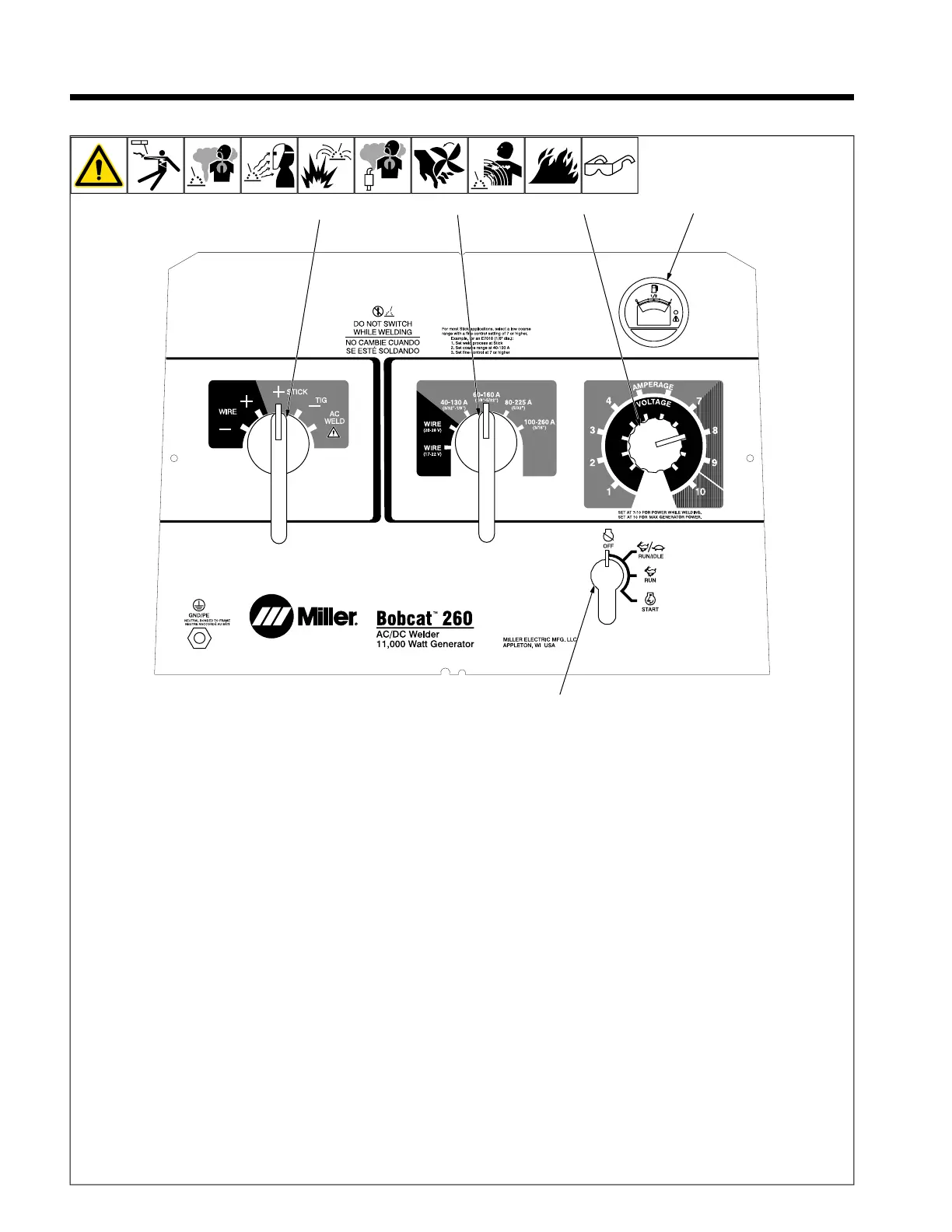

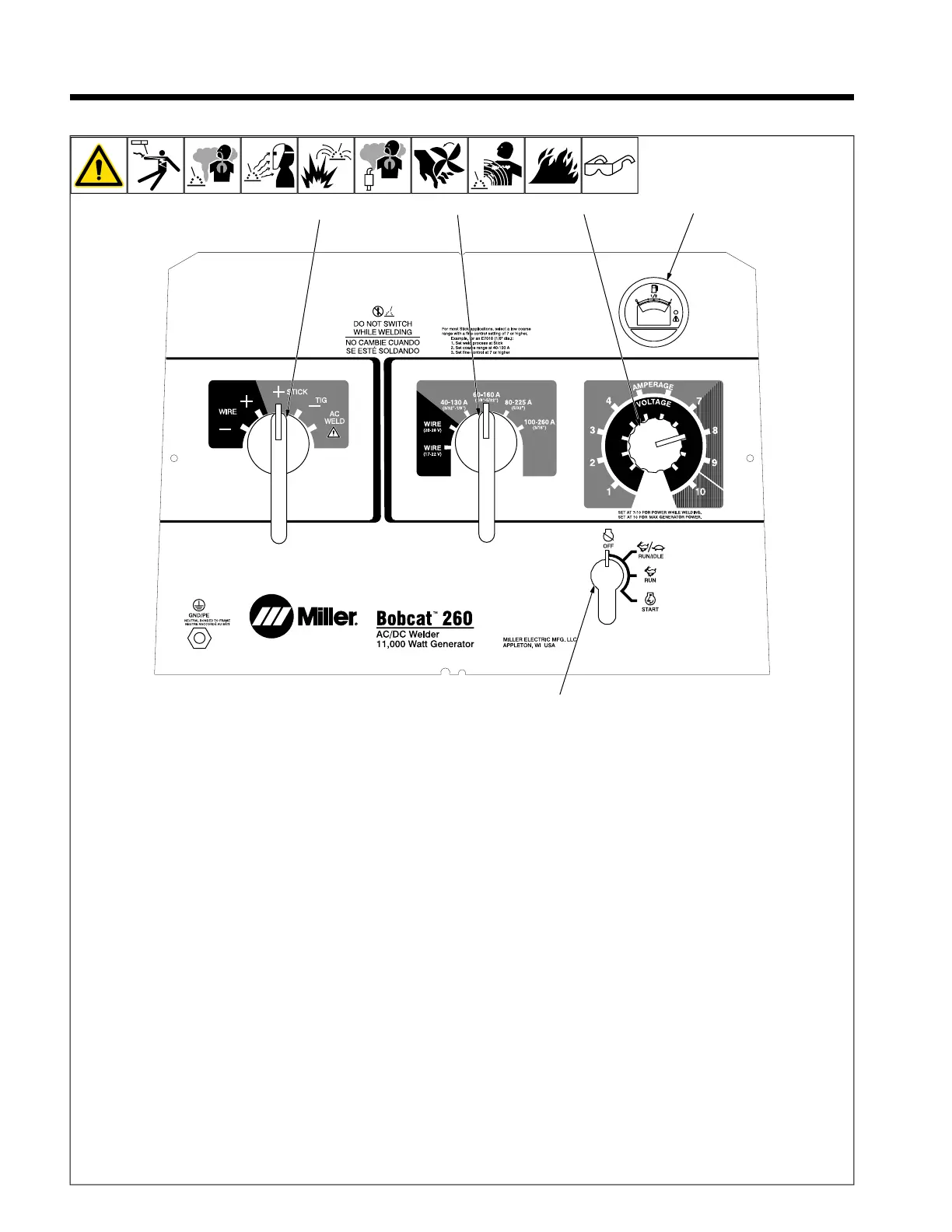

6-1. Front Panel Controls

1 Engine Control Switch

Use switch to start engine, select speed,

and stop engine. In Run/Idle position, en-

gine runs at idle speed at no load, and weld/

power speed under load. In Run position,

engine runs at weld/power speed.

F

Place switch in Run position to operate

most MIG equipment.

Use control to change engine air-fuel mix.

To Start: pull out choke (LP engine only)

and turn Engine Control switch to Start posi-

tion. Release switch when engine starts.

Slowly push in choke (LP engine only).

F

If the engine does not start, let engine

come to a complete stop before at-

tempting restart.

F

During cold weather some gasoline en-

gines encounter difficulties that are

easily remedied. See Section 6-3 and

Troubleshooting Tables.

To Stop: turn Engine Control switch to Off

position.

2 Engine Hour Meter/Fuel Gauge/Idle

Control

Low fuel is indicated by an orange flashing

light on the right side of the display.

A maintenance interval is reached when the

wrench icon appears in the display.

Hour Meter: With engine off, place Engine

Control switch in Run/Idle position to view

engine hours.

Oil Change Interval: With engine off, place

Engine Control switch in the Run position to

see hours before next oil change. Oil hours

start at 100 and count down to 0 (zero) (oil

change due).

F

Negative hours indicated when past

recommended oil change interval.

To reset, cycle Engine Control switch from

Run/Idle to Run three times within five sec-

onds (engine off).

3 Weld Process Selector Switch

NOTICE – Do not switch under load.

Use switch to select type of weld output.

Wire (GMAW) Welding: Use a positive (+)

position for Direct Current Electrode Positive

(DCEP) and a negative (-) position for Direct

Current Electrode Negative.

Stick (SMAW) and TIG (GTAW Welding):

Use a positive (+) position for Direct Current

Electrode Positive (DCEP) and a negative

(-) position for Direct Current Electrode

Negative. Use AC position for alternating

current.

4 Coarse Range Switch

NOTICE – Do not switch under load.

Use switch to select weld amperage range

when Weld Process Selector switch is in

Stick/Tig position, or voltage range when

switch is in Wire position.

F

For best arc starts and when using

weld and generator power together,

use a low Coarse Range setting with

the Fine control set at 7 or higher.

5 Fine Control

Use control to select weld amperage (Stick/

Tig) or voltage (Wire) within the range se-

lected by the Coarse Range switch. Control

may be adjusted while welding.

Set control at 10 for maximum generator

power.

Weld output would be about 128 A DC

based on control settings shown (80% of 60

to 160 A). Settings shown are typical for

welding with a 7018 (1/8) electrode.

F

See Sections 6-4 thru 6-6 for typical

process connections and control

settings.

Loading...

Loading...