OM-286504 Page 60

SECTION 12 – STICK WELDING (SMAW) GUIDELINES

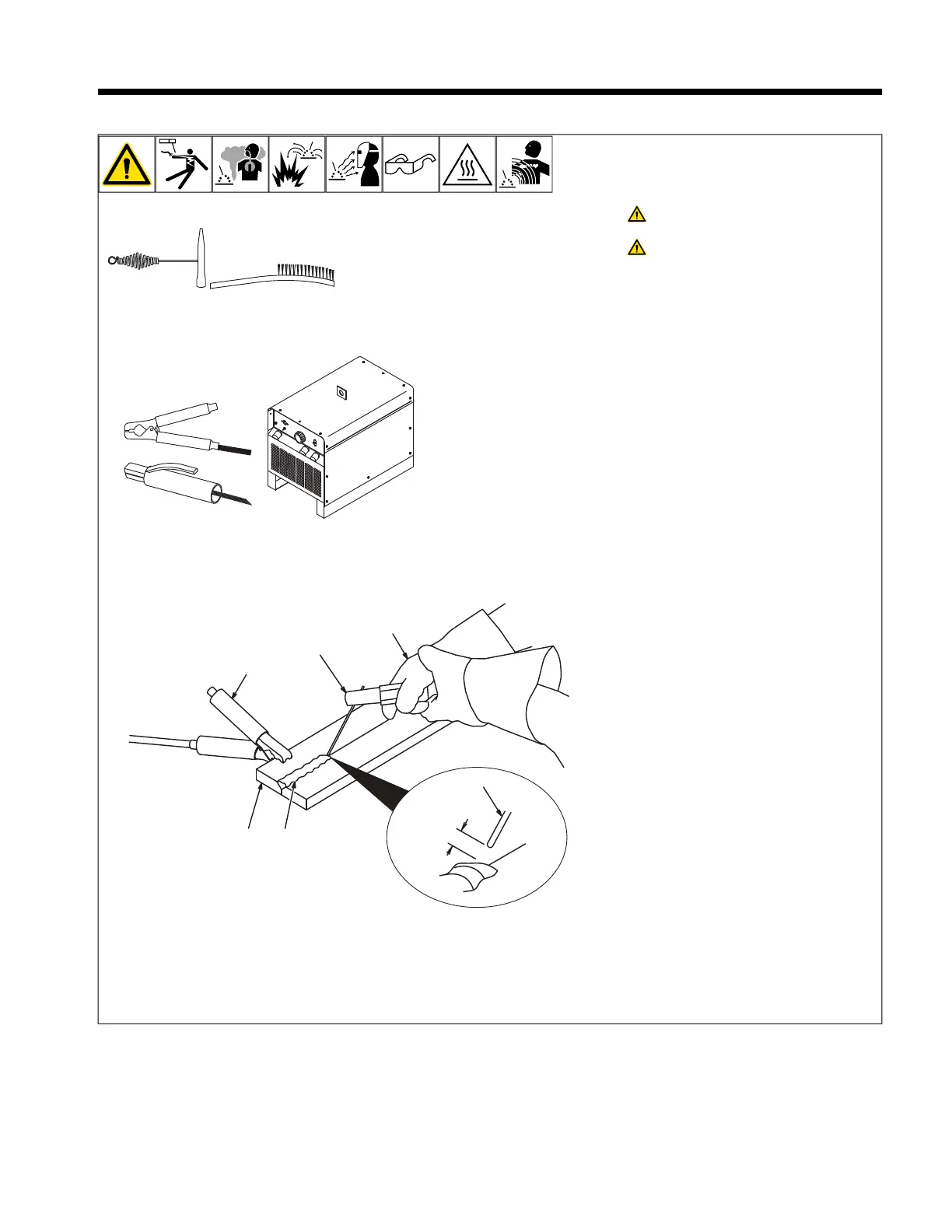

12-1. Stick Welding Procedure

Tools Needed:

OM-222 Page 1

allen_wrench

NGO’s

tools/

flathead philips head wrench

p

liers

knife

heavy-duty workclamp light-duty workclamp wirecutter frontcutter

allen_set

n

eedlenose

steelbrush nutdriver

chippinghammer

solderiron

stripcrimp

drill

t

orque wrench

socket wrench

hammer awl file

crimper

paintbrush

feelergauge flashlight ruler

t

oothbrush

greasegun

qtip (swab)

vicegrip

handream

p

unch

filterwrench

strapwrench

airgun

s

olvent

p

inextractor

e

prompuller

p

ipewrench

torque screwdriver

crescent wrench

OM-222 Page 1

allen_wrench

NGO’s

tools/

flathead philips head wrench

pliers

knife

heavy-duty workclamp light-duty workclamp wirecutter frontcutter

allen_set

needlenose

steelbrush nutdriver

chippinghammer

solderiron

stripcrimp

drill

torque wrench

socket wrench

hammer awl file

crimper

paintbrush

feelergauge flashlight ruler

toothbrush

greasegun

qtip (swab)

vicegrip

handream

punch

filterwrench

strapwrench

airgun

solvent pinextractor eprompuller pipewrench

torque screwdriver

crescent wrench

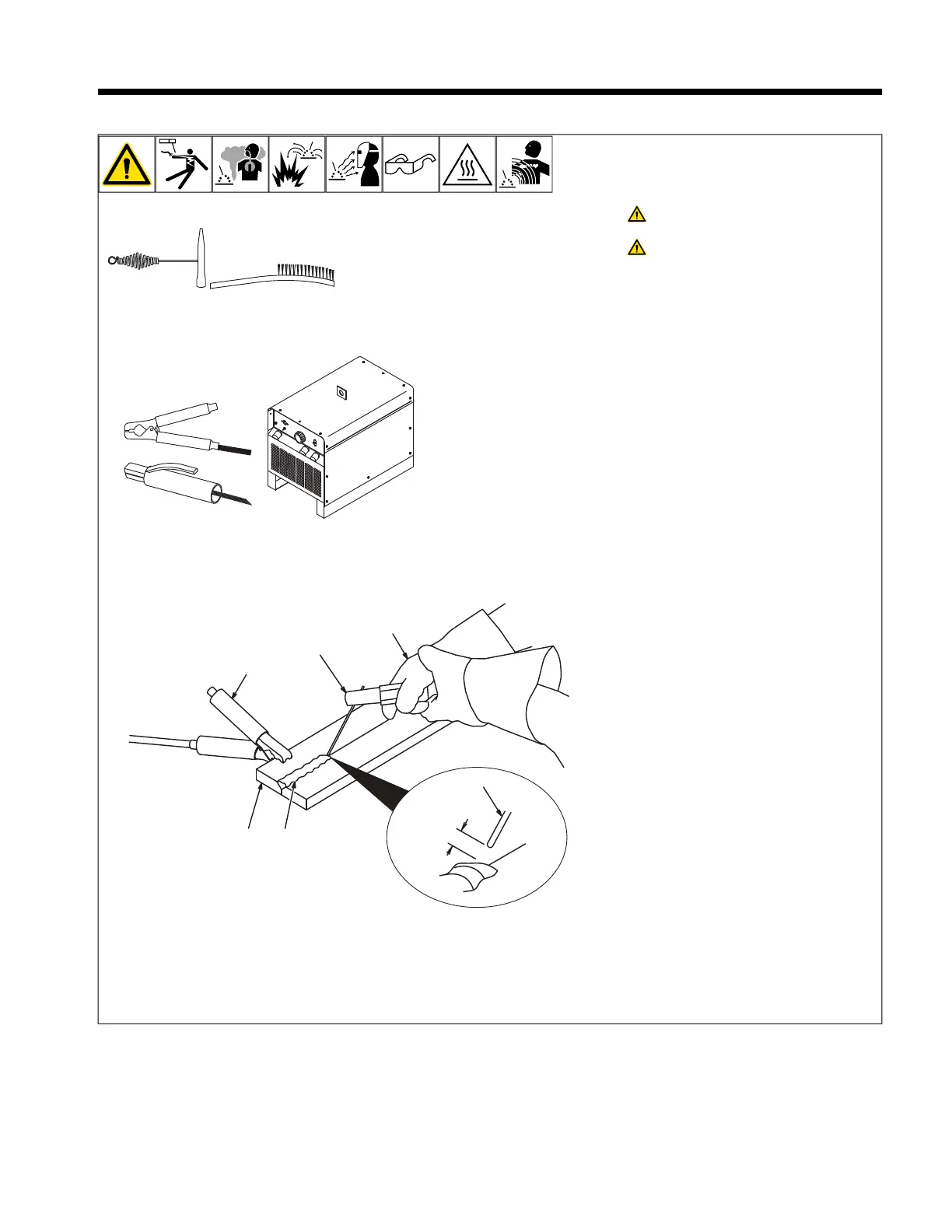

Equipment Needed:

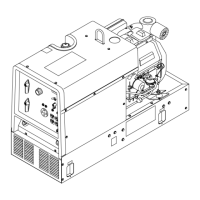

Weld current starts when electrode

touches workpiece.

Weld current can damage elec-

tronic parts in vehicles. Discon-

nect both battery cables before

welding on a vehicle. Place work

clamp as close to the weld as

possible.

F

Always wear appropriate personal pro-

tective clothing.

1 Workpiece

Make sure workpiece is clean before

welding.

2 Work Clamp

Place as close to the weld as possible.

3 Electrode

Before striking an arc, insert an electrode in

the electrode holder. A small diameter elec-

trode requires less current than a large one.

Follow recommendations of the electrode

manufacturer when setting weld amperage

(see Section 12-2).

4 Insulated Electrode Holder

5 Electrode Holder Position

6 Arc Length

Arc length is the distance from the electrode

to the workpiece. A short arc with correct

amperage will give a sharp, crackling sound.

Correct arc length is related to electrode di-

ameter. Examine the weld bead to determine

if the arc length is correct.

Arc length for 1/16 and 3/32 in. diameter

electrodes should be about 1/16 in. (1.6

mm); arc length for 1/8 and 5/32 in. electro-

des should be about 1/8 in. (3 mm).

7 Slag

Use a chipping hammer and wire brush to re-

move slag. Remove slag and check weld

bead before making another weld pass.

Loading...

Loading...