OM-286504 Page 31

F

Complete Parts List is available at www.MillerWelds.com

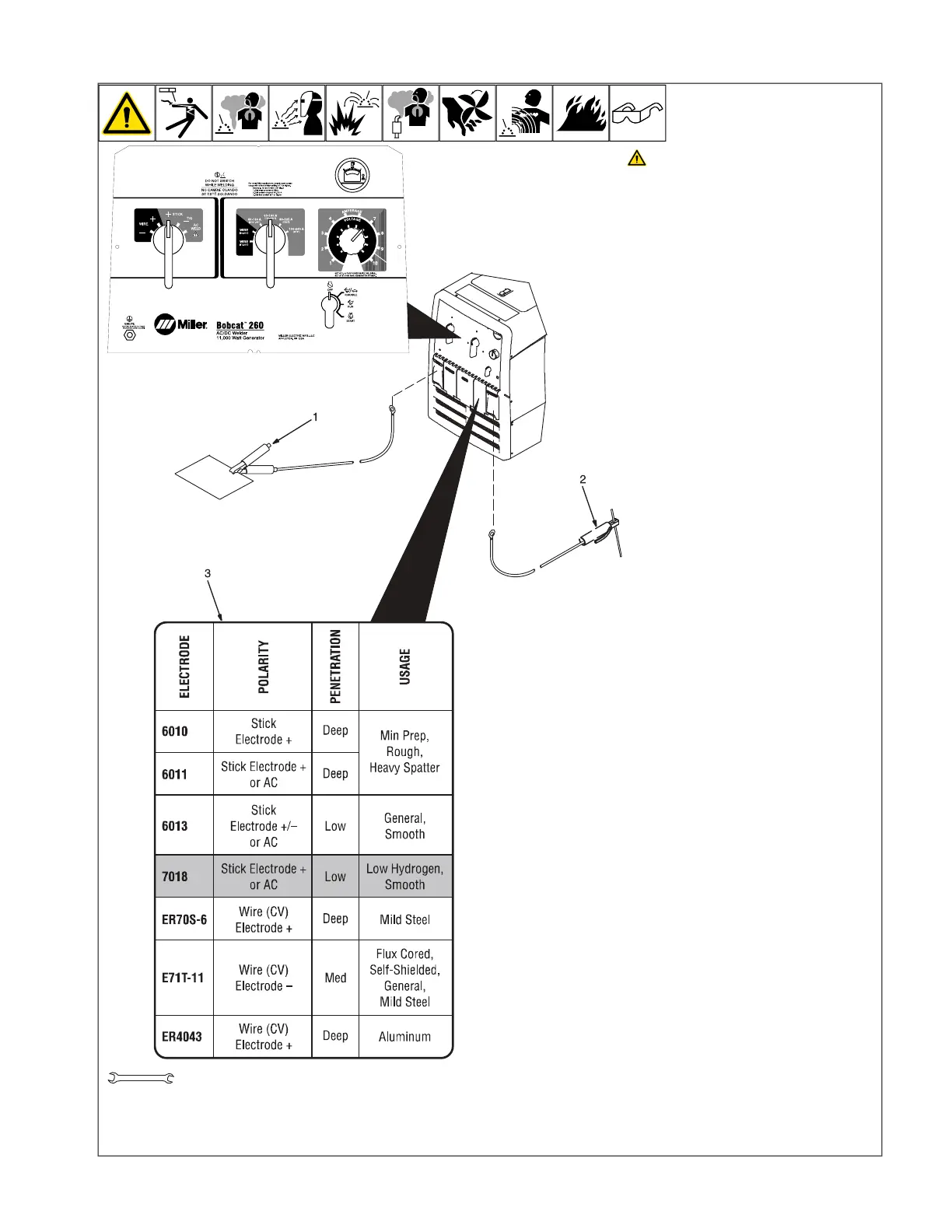

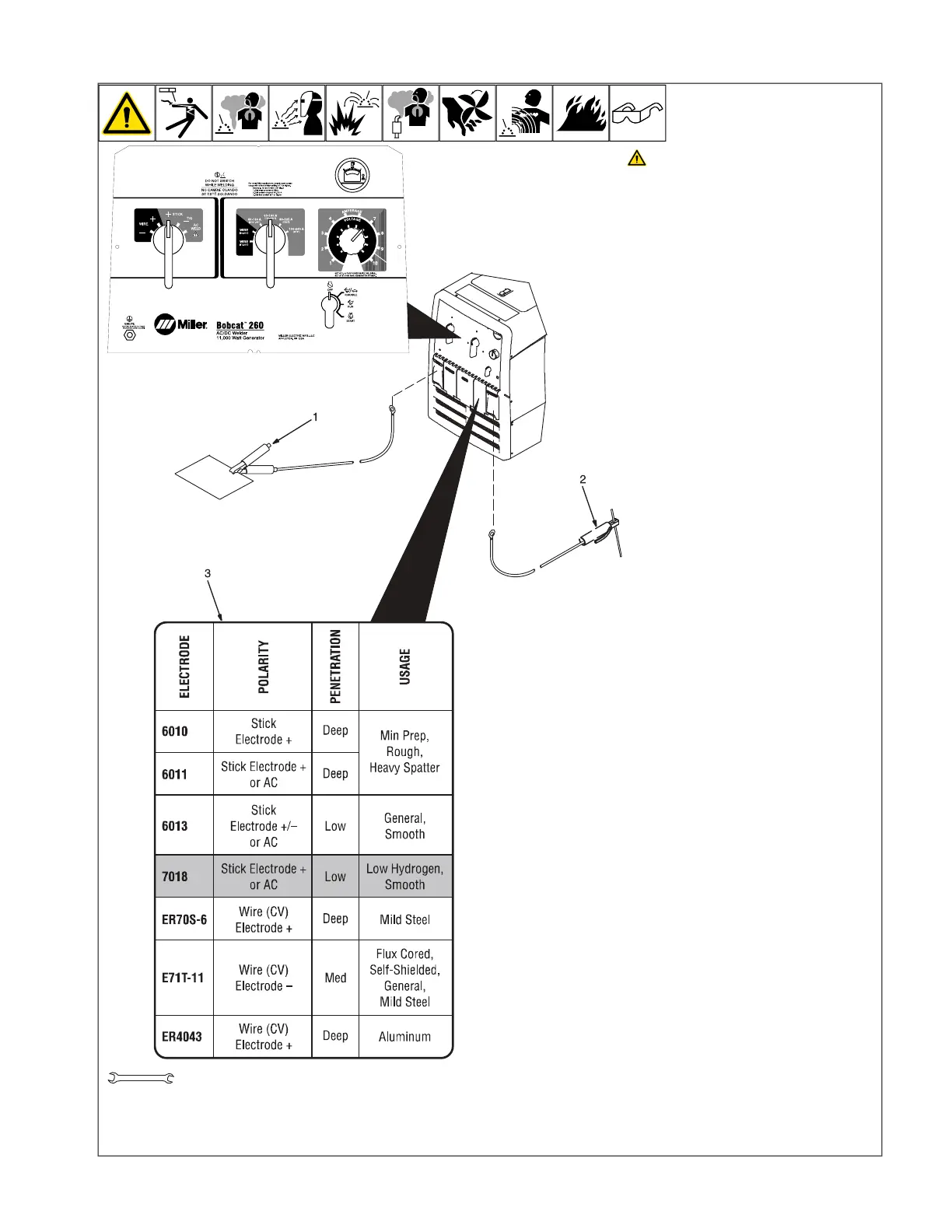

6-4. Typical Stick Welding Connections And Control Settings

OM-222 Page 1

allen_wrench

NGO’s

tools/

flathead philips head wrench

pliers

knife

heavy-duty workclamp light-duty workclamp wirecutter frontcutter

allen_set

needlenose

steelbrush nutdriver

chippinghammer

solderiron

stripcrimp

drill

torque wrench

socket wrench

hammer awl file

crimper

paintbrush

feelergauge flashlight ruler

toothbrush

greasegun

qtip (swab)

vicegrip

handream

punch

filterwrench

strapwrench

airgun

solvent pinextractor eprompuller pipewrench

torque screwdriver

crescent wrench

3/4 in.

Stop engine.

F

This section provides general guide-

lines and may not suit all applications.

F

The control panel shows the typical set-

tings for welding with a 7018 (1/8 in.)

electrode. Consult the amperage se-

lection tables below if welding with oth-

er electrodes.

1 Work Clamp

2 Electrode Holder

3 Electrode Selection Table (Beneath

Cover)

Connect Work cable to Work terminal and

Electrode holder cable to Electrode terminal

on welding generator.

F

Be sure to use the correct size weld ca-

bles (see Section 5-9).

F

For best performance, set the Coarse

Range switch to the lowest range that

covers the desired weld amperage.

Use the Fine control to select the de-

sired amperage within the range se-

lected. When properly set, the Fine

control is normally set at 7 or higher.

Typical Settings For 7018 (1/8 in.)

Electrode:

l Set Weld Process Selector switch to +

Stick position.

l Set Coarse Range switch to 60-160 (1/

8”) position.

l Set Fine control at 7 or higher for best

results.

F

Miller recommends Hobart filler metals.

Loading...

Loading...