OM-286504 Page 62

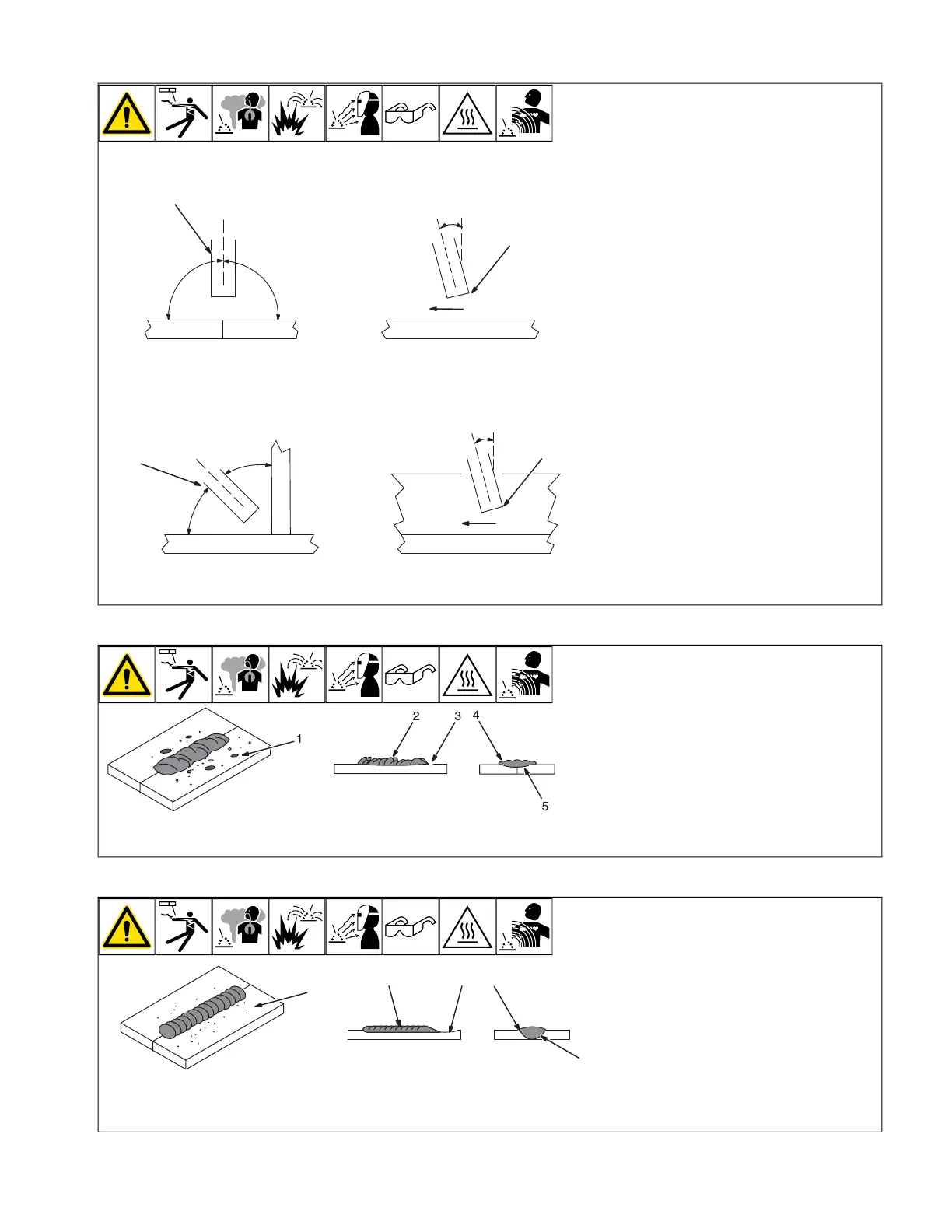

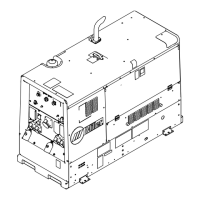

12-4. Positioning Electrode Holder

Groove Welds

OM-

90

°

90

°

10°-30°

45°

45

°

10°-30°

1

1

2

2

Fillet Welds

OM-

90

°

90

°

10

°

-30

°

45

°

45

°

10

°

-30

°

1

1

2

2

1 End View Of Work Angle

2 Side View Of Electrode Angle

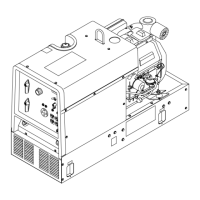

After learning to start and hold an arc, prac-

tice running beads of weld metal on flat

plates using a full electrode.

Hold the electrode nearly perpendicular to

the work, although tilting it ahead (in the di-

rection of travel) will be helpful.

F

To produce the best results, hold a

short arc, travel at a uniform speed,

and feed the electrode downward at a

constant rate as it melts.

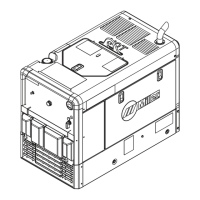

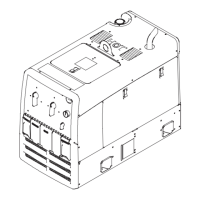

12-5. Poor Weld Bead Characteristics

1 Large Spatter Deposits

2 Rough, Uneven Bead

3 Slight Crater During Welding

4 Bad Overlap

5 Poor Penetration

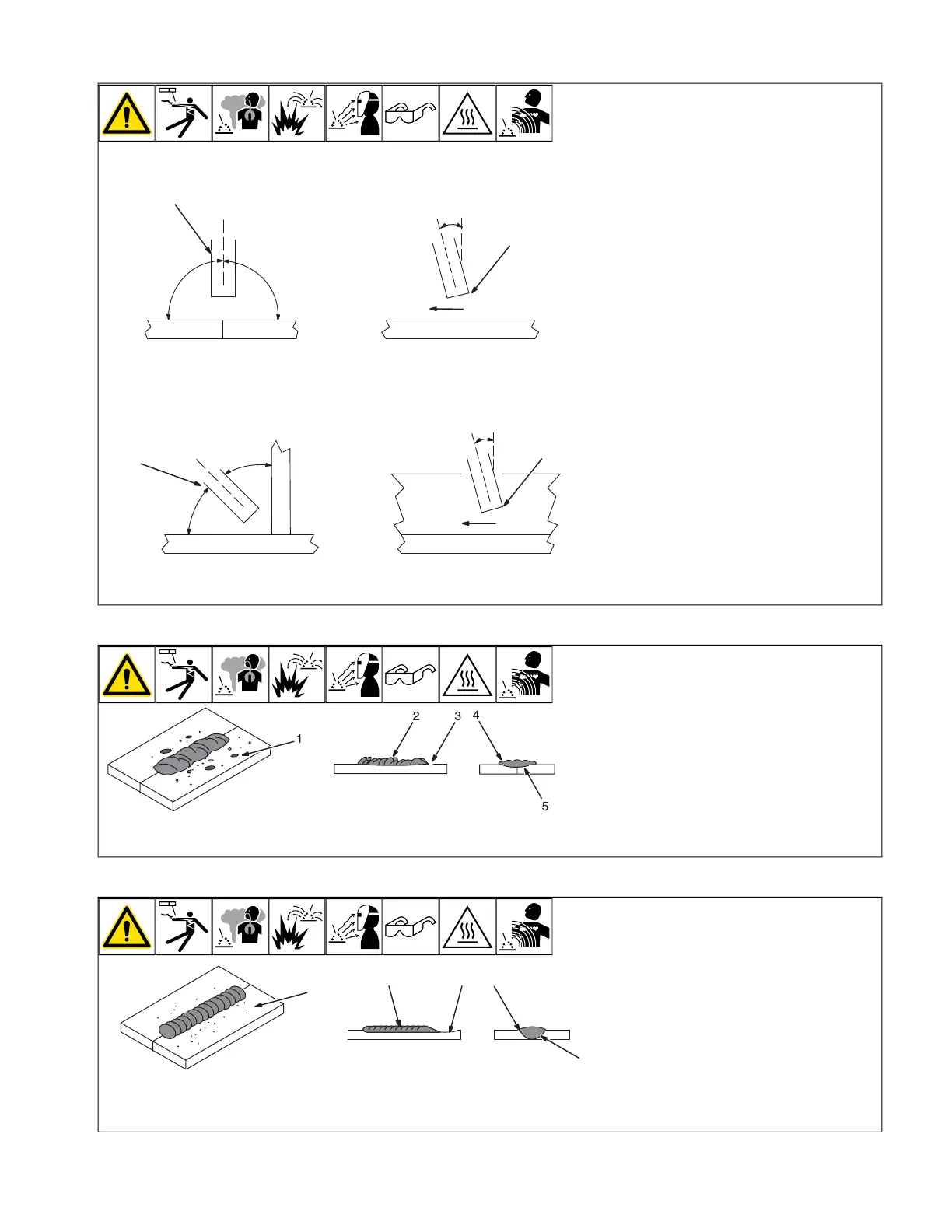

12-6. Good Weld Bead Characteristics

OM-4419 Page 1

3

1

2

5

4

2

3

1

2

3

1

4

5

1 Fine Spatter

2 Uniform Bead

3 Moderate Crater During Welding

Weld a new bead or layer for each 1/8 in.

(3.2 mm) thickness in metals being welded.

4 No Overlap

5 Good Penetration into Base Metal

Loading...

Loading...