Chapter 3. Routine Maintenance

PELLERIN MILNOR CORPORATION

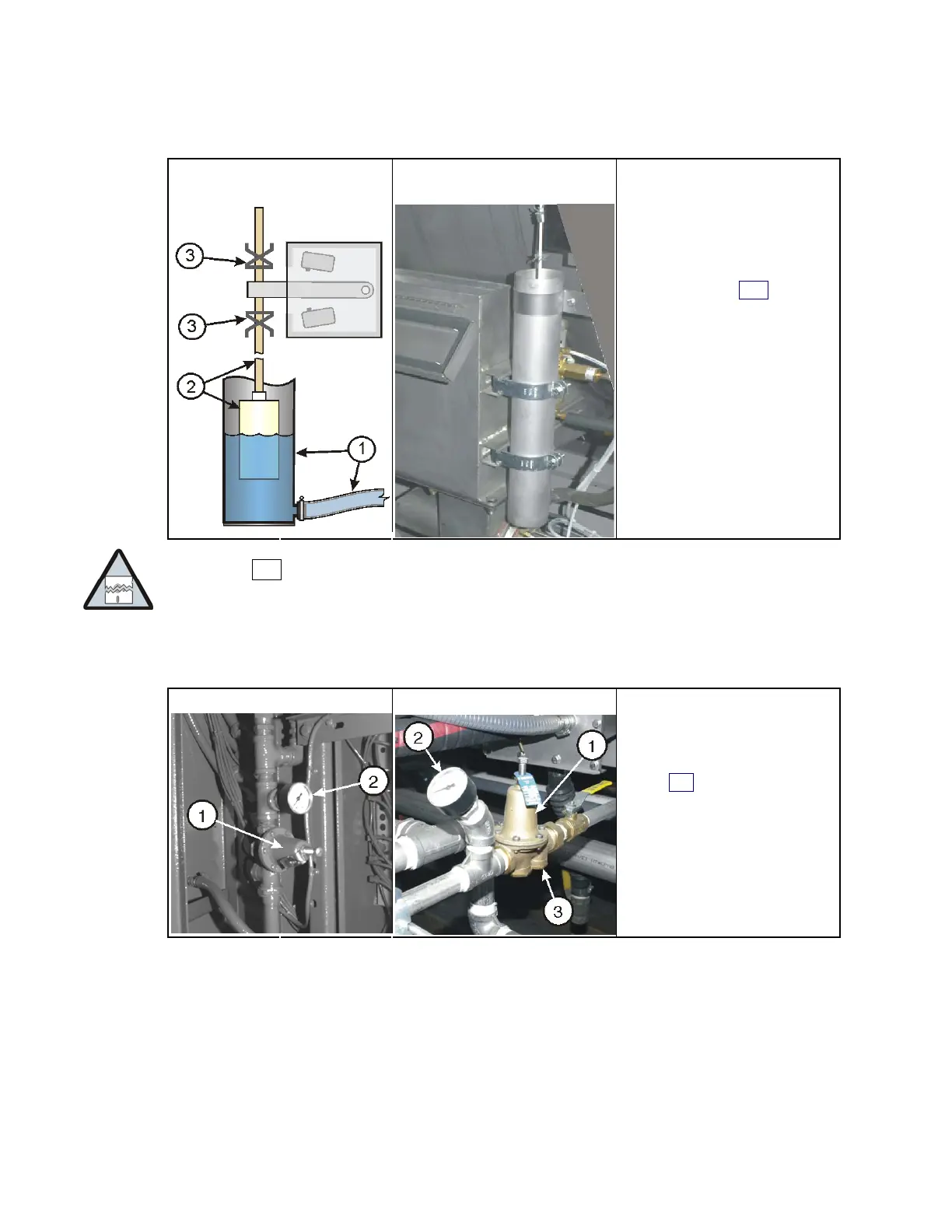

Figure 13: Level Float Assembly. These are examples. Your machine can look different.

Typical Level Float Assembly 76039 CBW Module Level

Float

Legend

.

1. Float tube and connecting

hose. Remove lint that

can prevent correct

operation. See

caution

statement 33

.

2. Float and rod. The float

must be free to move as

the water level changes..

3. Clips. If it is necessary to

move the clips to remove

the float and rod, put

marks on the rod so you

can replace the clips

accurately.

CAUTION 33 : Risk of malfunction—The level sensor must give correct data.

• Keep the connecting tube or hose free of blockages and leaks.

• Make sure that the connections are tight.

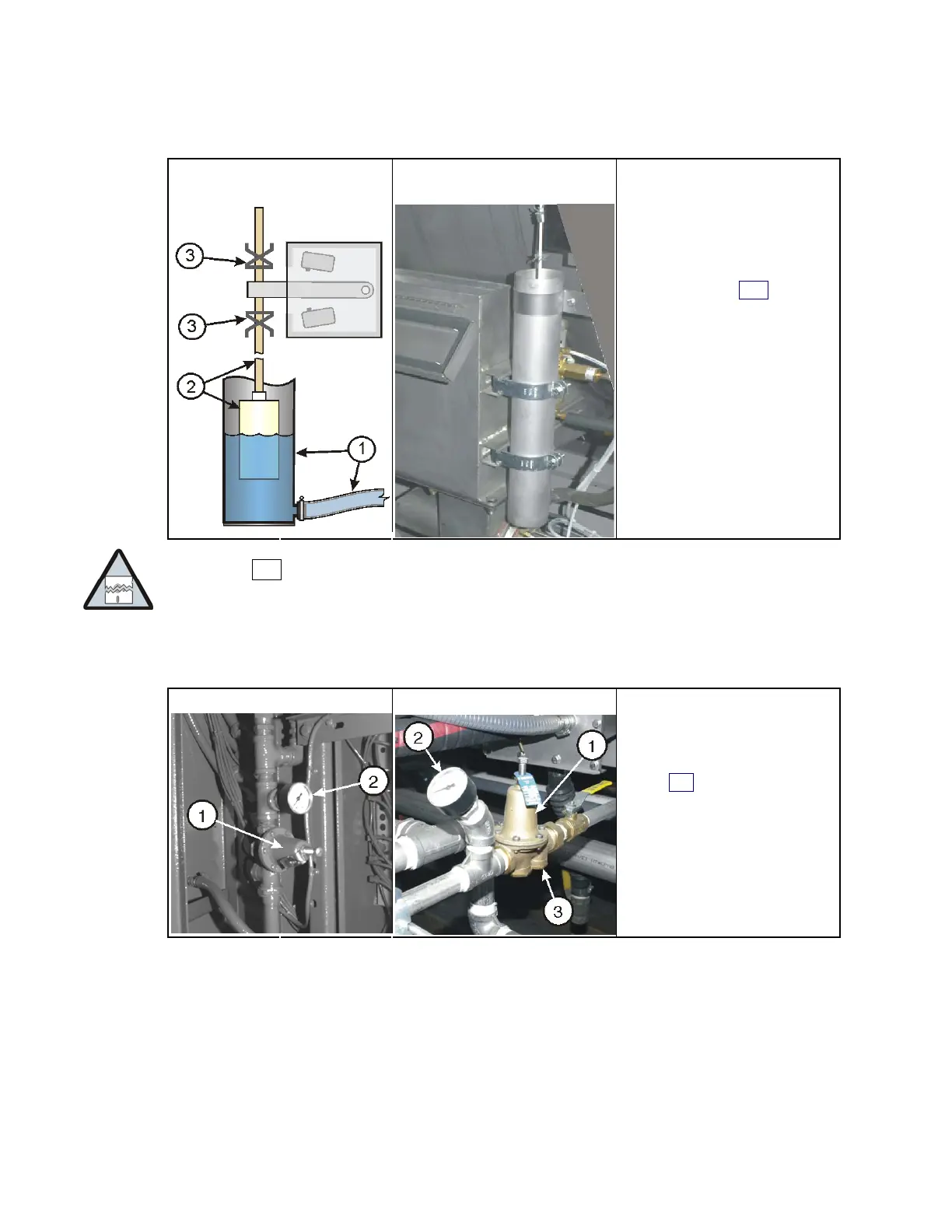

Figure 14: Water Pressure Regulator for Chemical Flush. These are examples. Your machine can

look different.

64050E6N Washer-extractor 76039CBW Tunnel Washer Legend

.

1. Water pressure regulator

2. Water pressure gauge

3. See

caution statement

35

. Remove plug to

remove strainer.

40

Loading...

Loading...