MS50SF7

Specification V1.0

www.minewsemi.com minewsemi@minew.com Copyright

©

Shenzhen Minewsemi Co., Ltd.

This manual and all the contents contained in it are owned by Shenzhen Minewsemi Co., Ltd. and are protected by Chinese laws and applicable international conventions related to

copyright laws.The company has the right to change the content of this manual according to the technological development, and the revised version will not be notified otherwise.

Without the written permission and authorization of the company, any individual, company, or organization shall not modify the contents of this manual or use part or all of the

contents of this manual in other ways. Violators will be held accountable in accordance with the law.

1)

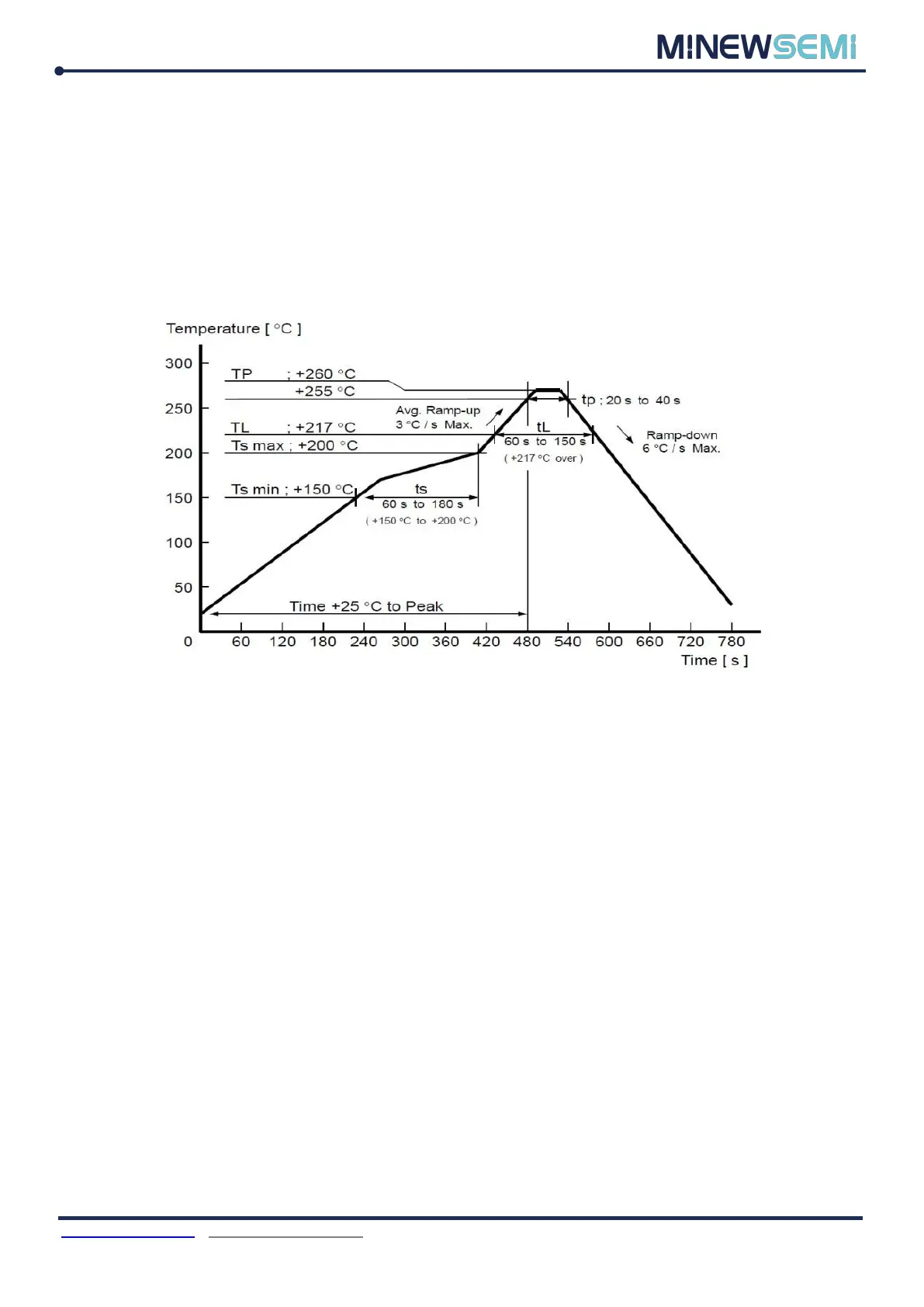

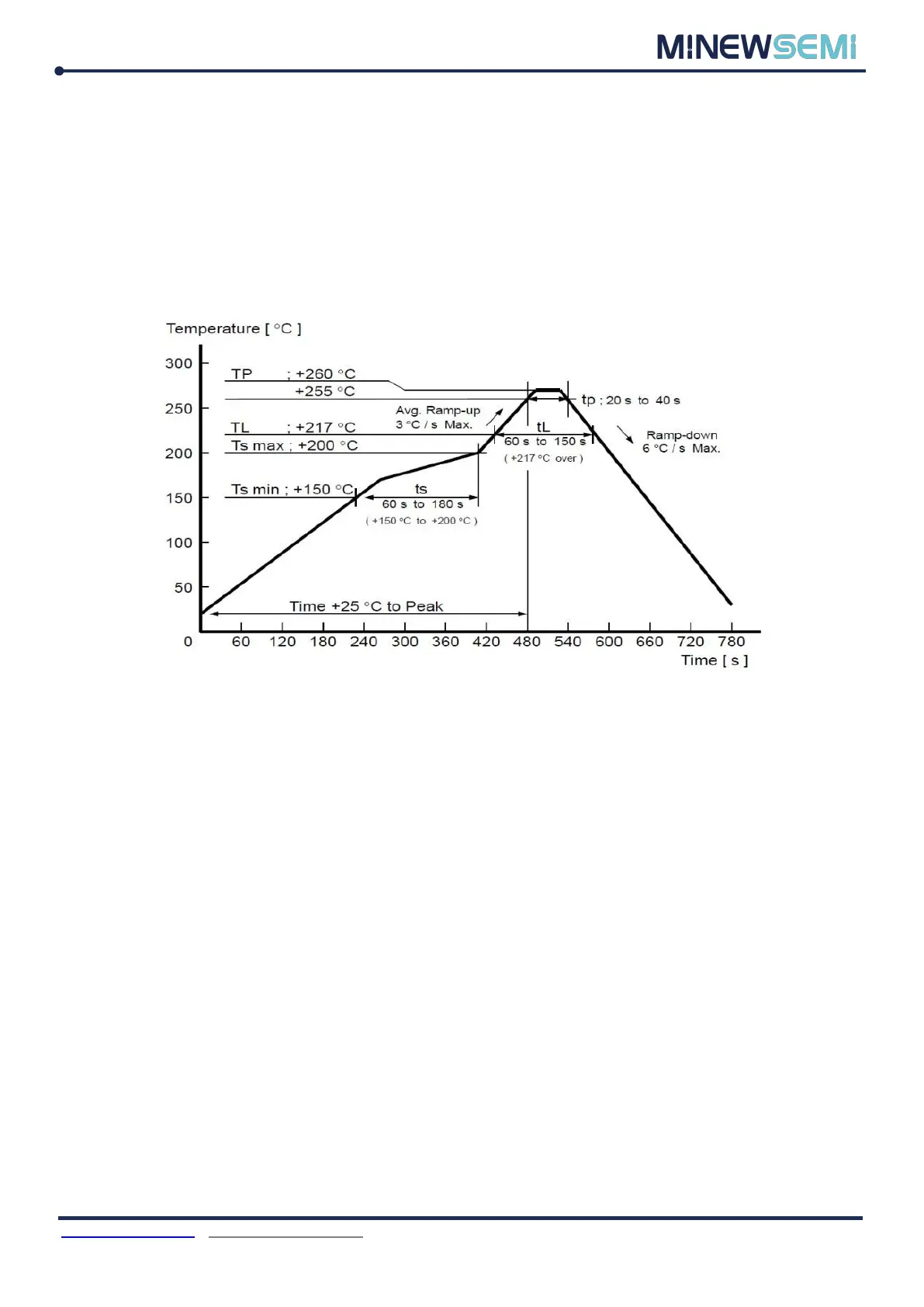

Do SMT according to above reflow oven temperature deal curve. Max. Temperature is

260

℃

;

Refer to IPC/JEDEC standard

;

Peak TEMP<260

℃;

Times

:

≤2 times

,

suggest only do once

reflow soldering on module surface in case of SMT double pad involved. Contact us if

special crafts involved.

2)

Suggesting to make 0.2mm thickness of module SMT for partial ladder steel mesh, then

make the opening extend 0.8mm

3) After unsealing, it cannot be used up at one time, should be vacuumed for storage, couldn’t

be exposed in the air for long time. Please avoid getting damp and soldering-pan oxidizing.

If there are 7 to 30 days interval before using online SMT, suggest to bake at 65-70

℃

for

24 hours without disassembling the tape.

4)

Before using SMT, please adopt ESD protection measure.

Loading...

Loading...