47

Dowel Drill Manual

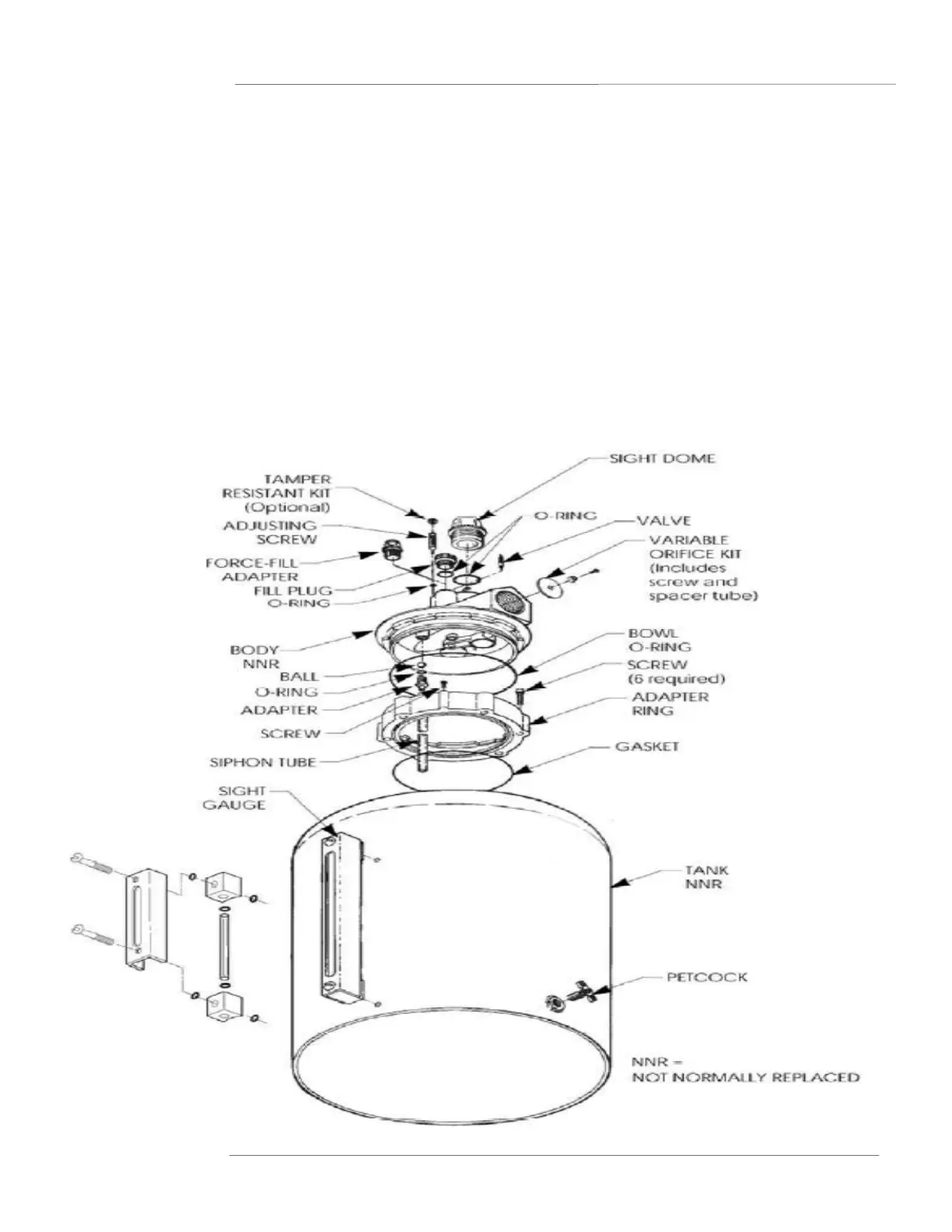

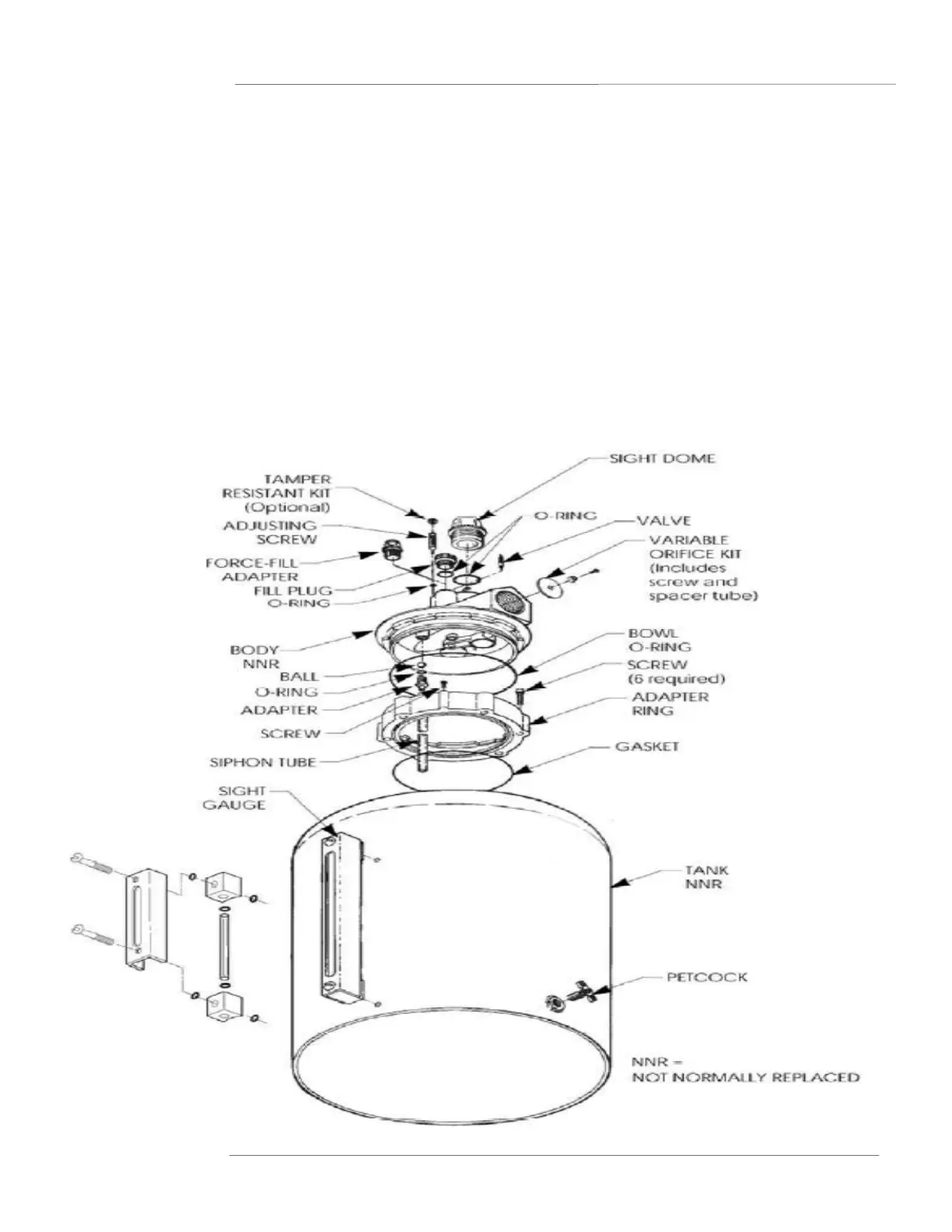

OILER INFORMATION

MAINTENANCE

1. Given clean operating conditions, this unit should be trouble-free. Contaminants from dirty oil may col-

lect on the siphon tube inlet lter, requiring the lter to be cleaned by tapping on a hard surface and blow-

ing off with an air blow gun. Drain off any contaminants which collect in the bottom of the bowl.

2. IF THE OIL DELIVERY RATE DROPS, shut off the air supply to the lubricator and reduce the pressure in

the unit to zero. Remove the Flow-Guide® variable orice screw and clean its air passage with a small wire.

Check the bore that the screw ts into for contaminants and clean, if necessary. Be sure that the passageway

from the sight dome cavity into the Flow-Guide® variable orice post is open. Remove the adjusting screw

and clean the needle and the seat in the body. Inspect and clean the passage from the needle seat down

into the adaptor.

3. Drain off any contaminants which collect in the bottom of the bowl.

4. Lubricate o-rings with Parker O-Lube before assembly.

5. Clean plastic bowl with a clean, dry cloth only.

0A3843-00020 Rebuild Kit (Includes all parts except tank, body and sight gauge kit)

003843-00017 Sight Gauge kit for 007330-00000 (not included in 0A3843-00020)

003843-00005 Sight Dome Kit (included in 0A3843-00020)

Loading...

Loading...