Chapter 2 Specifications

2–9

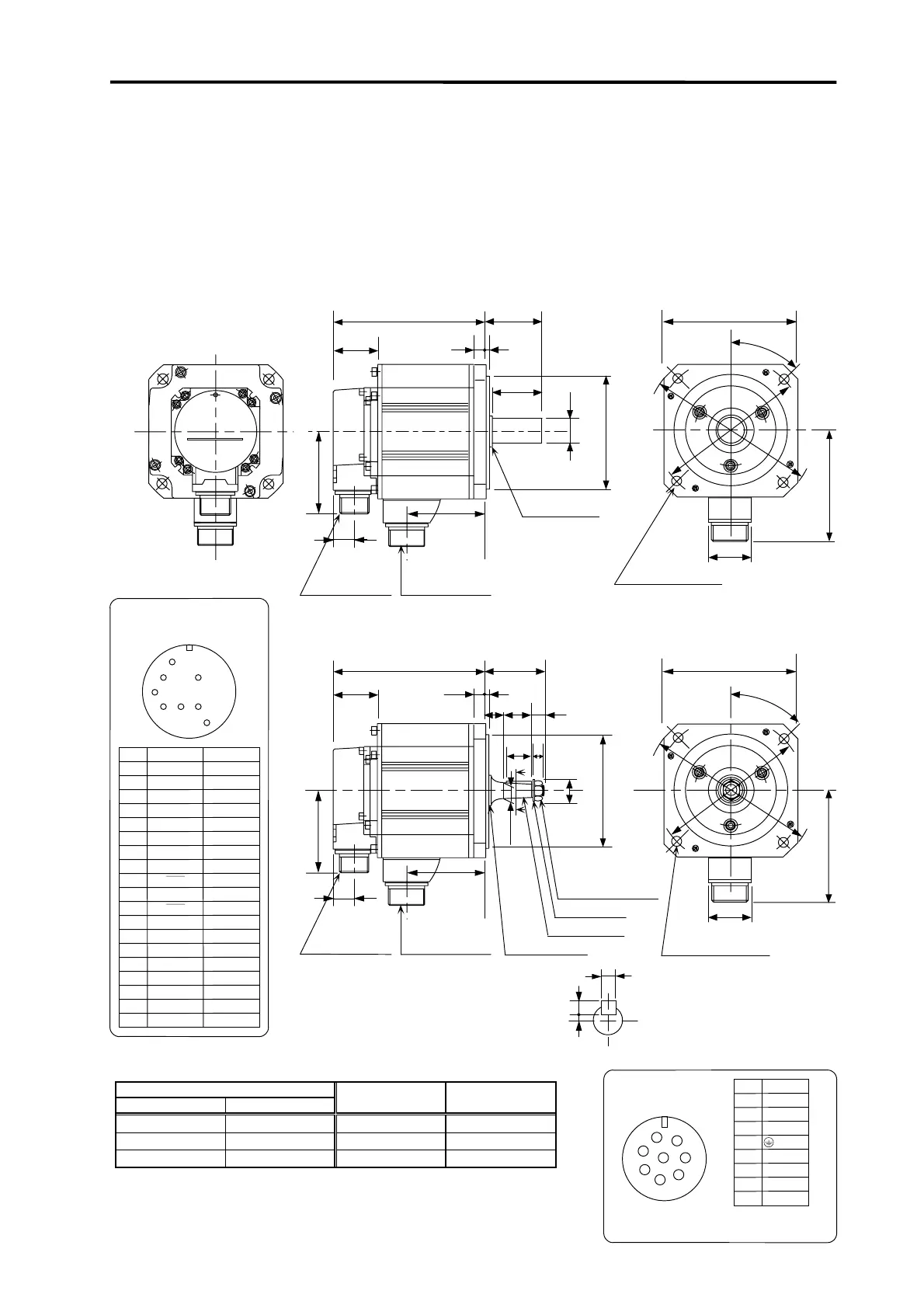

2-4 Outline dimension drawings

• HC52(B)S • HC52(B)T

• HC102(B)S • HC102(B)T

• HC152(B)S • HC152(B)T

• HC53(B)S • HC53(B)T

• HC103(B)S • HC103(B)T

• HC153(B)S • HC153(B)T

(Unit : mm)

S30457B

Oil seal

3

55

φ

110h7

φ

24h6

21.5

KL

81.5

12

L

44

CE05-2A22-23P

Power supply

connector

MS3102A22-14P

Detector

connector

50

□130

45°

4-φ9

Installation hole

Use a hexagon

socket head bolt.

φ

1

4

5

U nut M10×1.25

KL

81.5

5

0

-0.03

Cross section A-A

5

4.3

A

10

A

12 3

58

25

2818

12

φ

22

φ

110h7

Plain washer 10

Taper 1/10

φ

16.000

S30457B

L

44

CE05-2A22-23P

MS3102A22-14P

□130

45°

φ

1

4

5

41

111

φ

1

6

5

111

φ

1

6

5

21.5

Tightening torque

230~310 kgf・cm

41

Oil seal

Power supply

connector

Detector

connector

4-φ9

Installation hole

Use a hexagon

socket head bolt.

Servomotor type

2000r/min 3000r/min

L (Note 1) KL

HC52(B)□ HC53(B)□

125 (158) 51.5

HC102(B)□ HC103(B)□

150 (183) 76.5

HC152(B)□ HC153(B)□

175 (208) 101.5

Note 1. The dimensions given in parentheses are for when magnetic brakes

are provided.

Note 2. Use a friction coupling (Spun ring, etc.) to connect with the load.

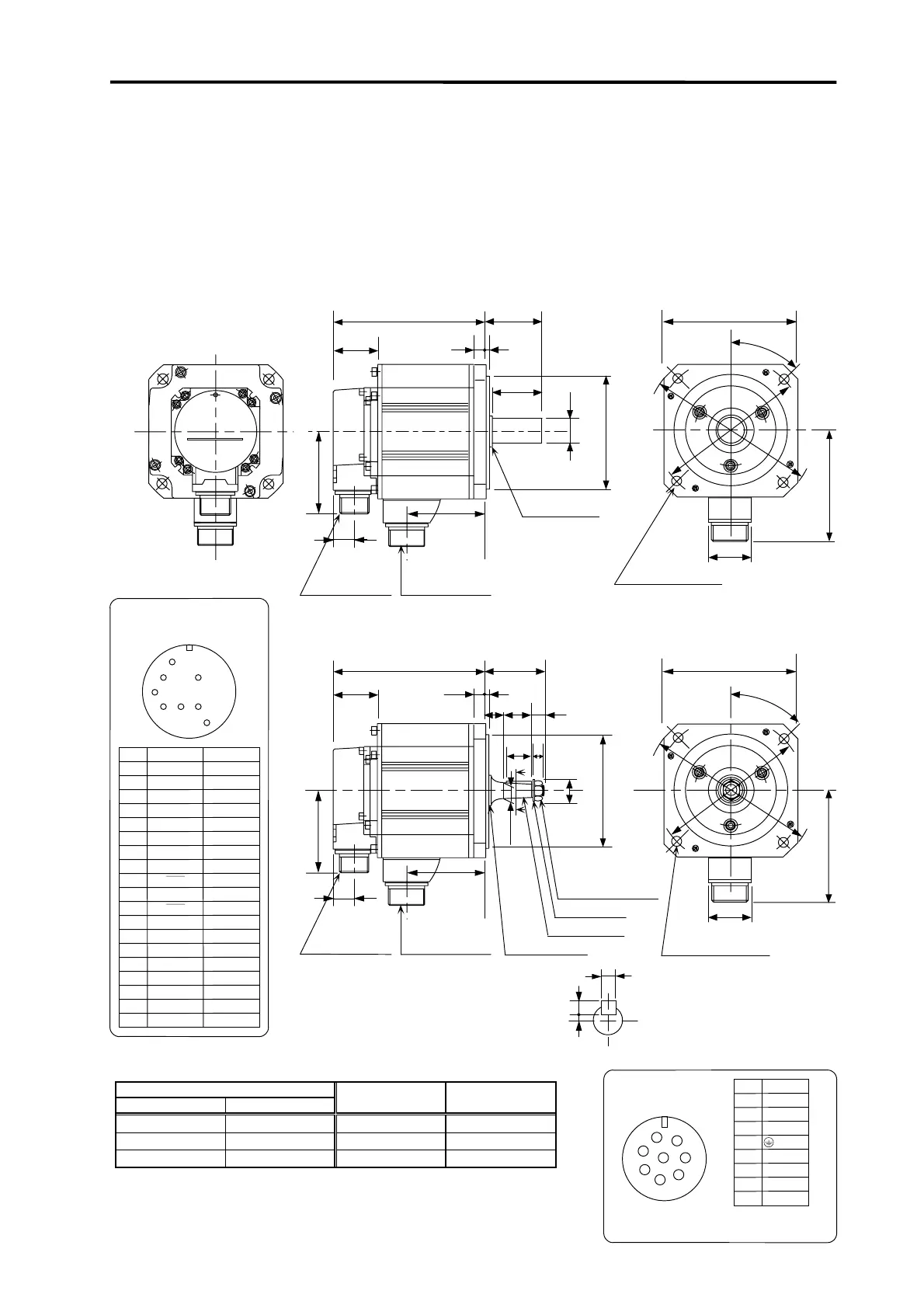

Power supply connector

CE05-2A22-23P

D

Signal

Grounding

U

V

W

B

A

Pin

C

E

F

B1

G

B2

H

A

B

C

HF

E

D

G

B1 and B2 are the brake terminals.

(Only for motor with brakes.)

24VDC with no polarity.

Detector connector

MS3102A22-14P

E

J

K

H

N

L

RS

VV

S+5V

SD

J

Vx signal

BT

B

SD

E

A

Pin

F

D

C

G

H

RQ

K

RQ

L

M

SD

N

P

5G

R

T

U

P5

+5V

MDR

SVJ2 signal

BAT

MD

MR

MRR

SD

LG

The detector connector is common for all HC motors.

Loading...

Loading...