Safety Check after Servicing

Examine the area surrounding the repaired location for

damage or deterioration. Observe that screws, parts,

and wires have been returned to their original positions.

Afterwards, do the following tests and confirm the speci-

fied values to verify compliance with safety standards.

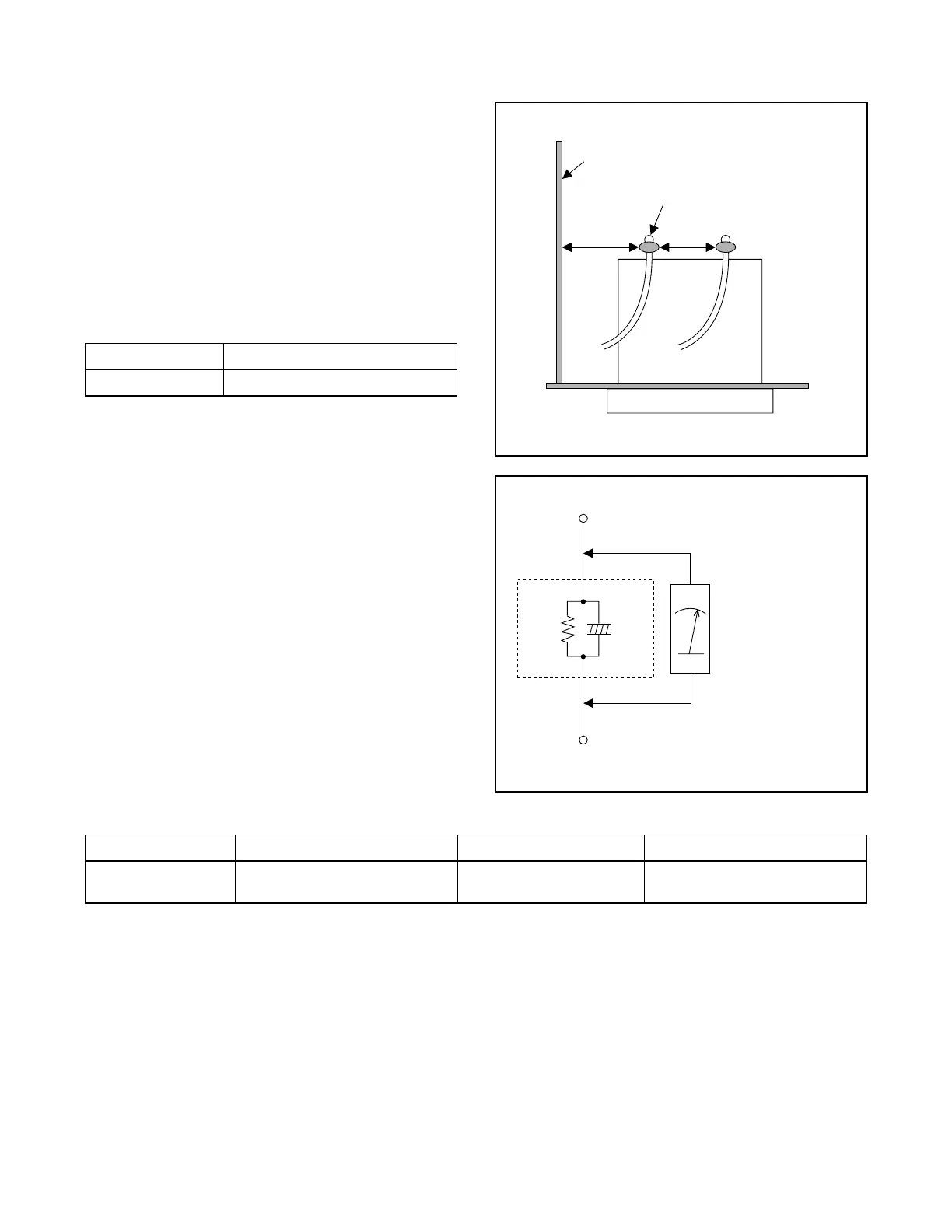

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between sol-

dered terminals, and between terminals and surround-

ing metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

AC Line Voltage Clearance Distance (d) (d’)

120 V ≥ 3.2 mm (0.126 inches)

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

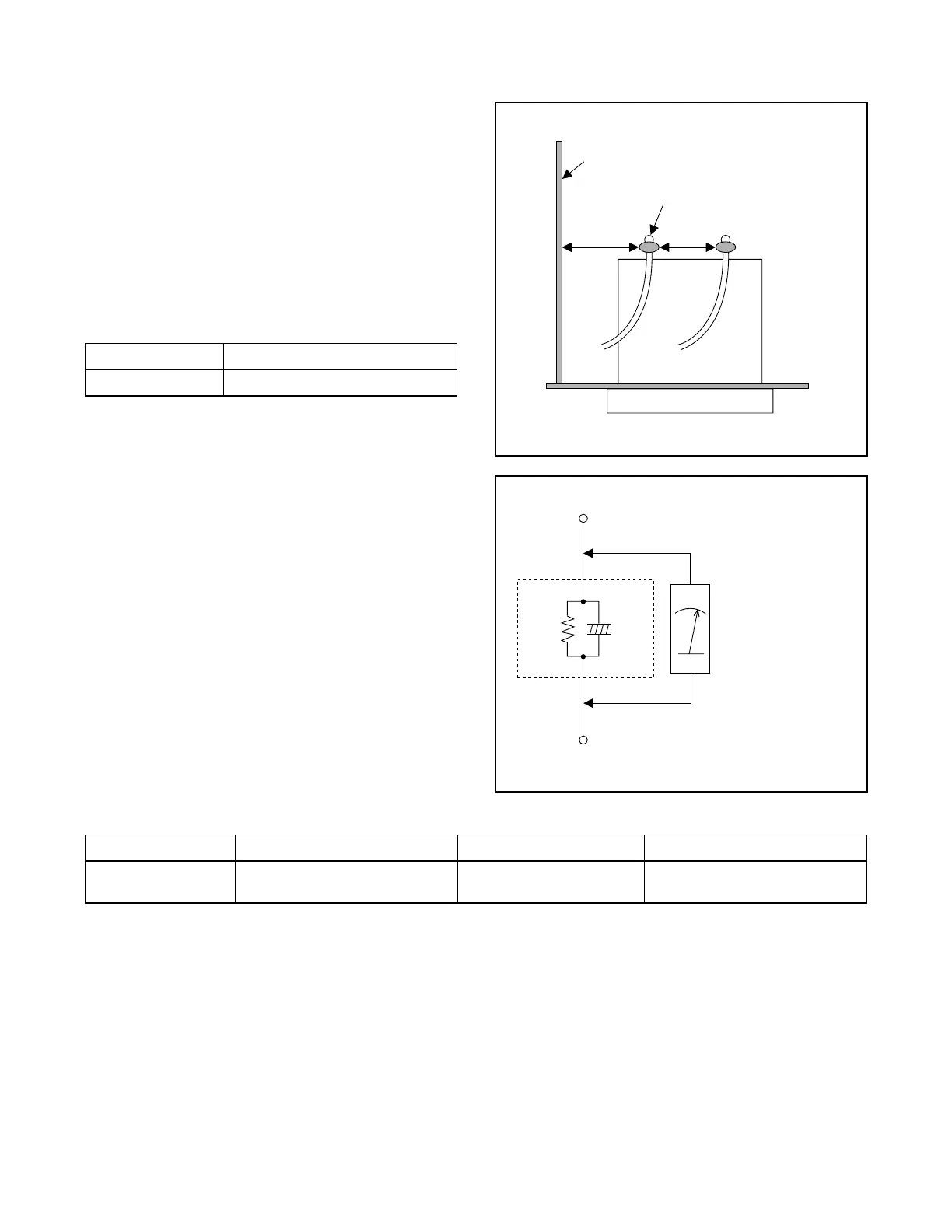

2. Leakage Current Test

Confirm the specified (or lower) leakage current be-

tween B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals, an-

tenna terminals, video and audio input and output ter-

minals, microphone jacks, earphone jacks, etc.) is lower

than or equal to the specified value in the table below.

Measuring Method (Power ON) :

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

Table 2 : Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

120 V

0.15µF CAP. & 1.5kΩ RES.

Connected in parallel

i ≤ 0.5mA Peak Exposed accessible parts

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

Chassis or Secondary Conductor

dd'

Primary Circuit Terminals

Fig. 1

AC Voltmeter

(High Impedance)

Exposed Accessible Part

B

Earth Ground

Power Cord Plug Prongs

Z

1.5kΩ

0.15µF

Fig. 2

1-3-2 DVD_SFN1

Loading...

Loading...