F9Q ENGINE – Cylinder Block

11A-14-3

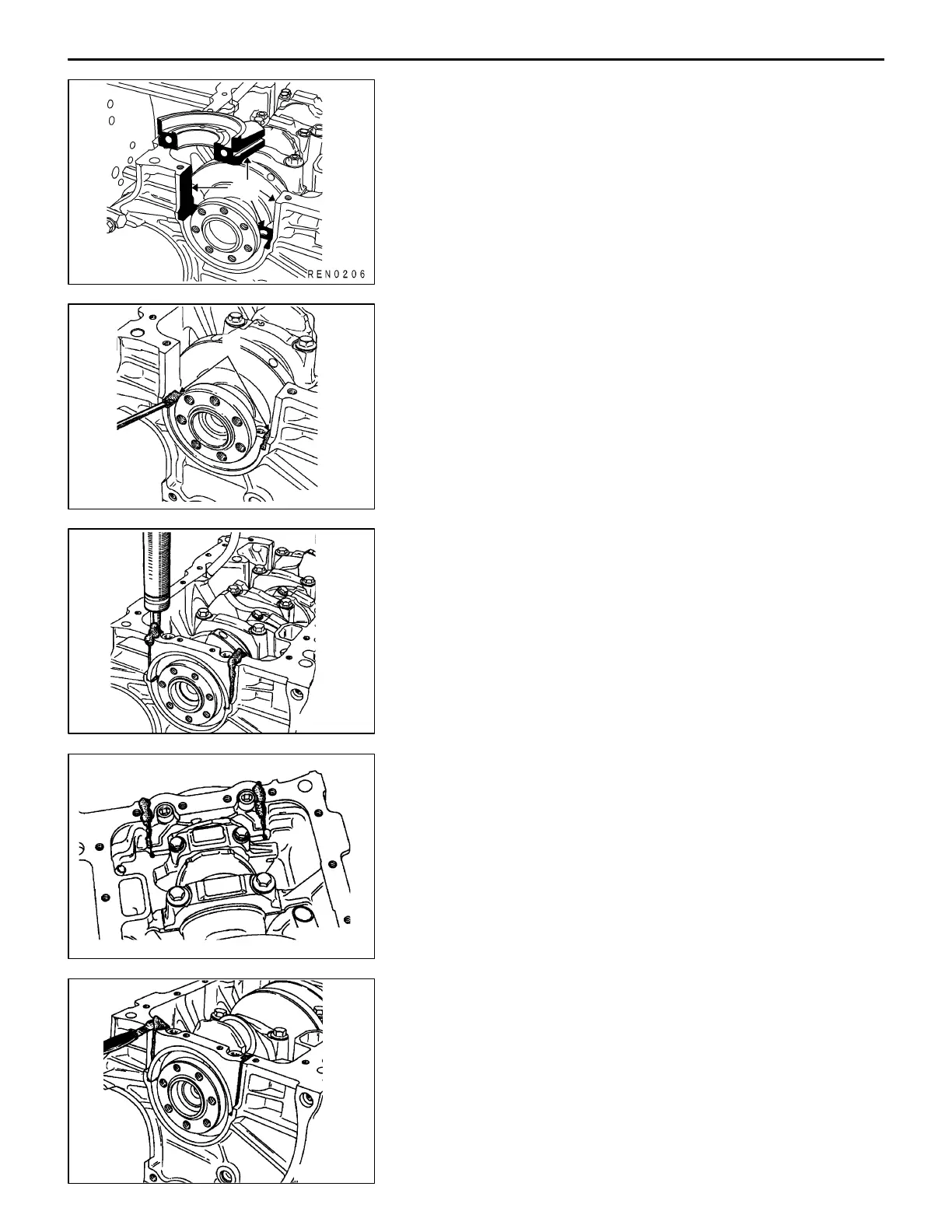

(5) Wipe the portions (shown as (A) in the illustration) on

the cylinder block and crankshaft bearing cap with shop

towel dampened with solvent.

Wait to dry the cleaned area and then proceed to the

next step.

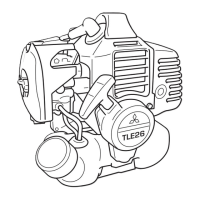

(6) Lightly coat the lower faces of the cylinder block at B

with Rhodorseal 5661.

(7) Fit the crankshaft bearing cap No. 1 and torque tighten

to 65 Nm.

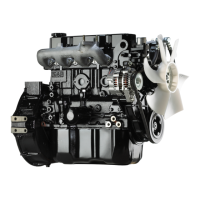

(8) Mix 45 ml of Rhodorseal 5661 (approximately half a 100

grammes tube) with half measure of hardener using a

small stick to give a slightly pink coloured, uniform mixture.

(9) Put the mixture into the syringe and inject it into the

crankshaft bearing cap grooves.

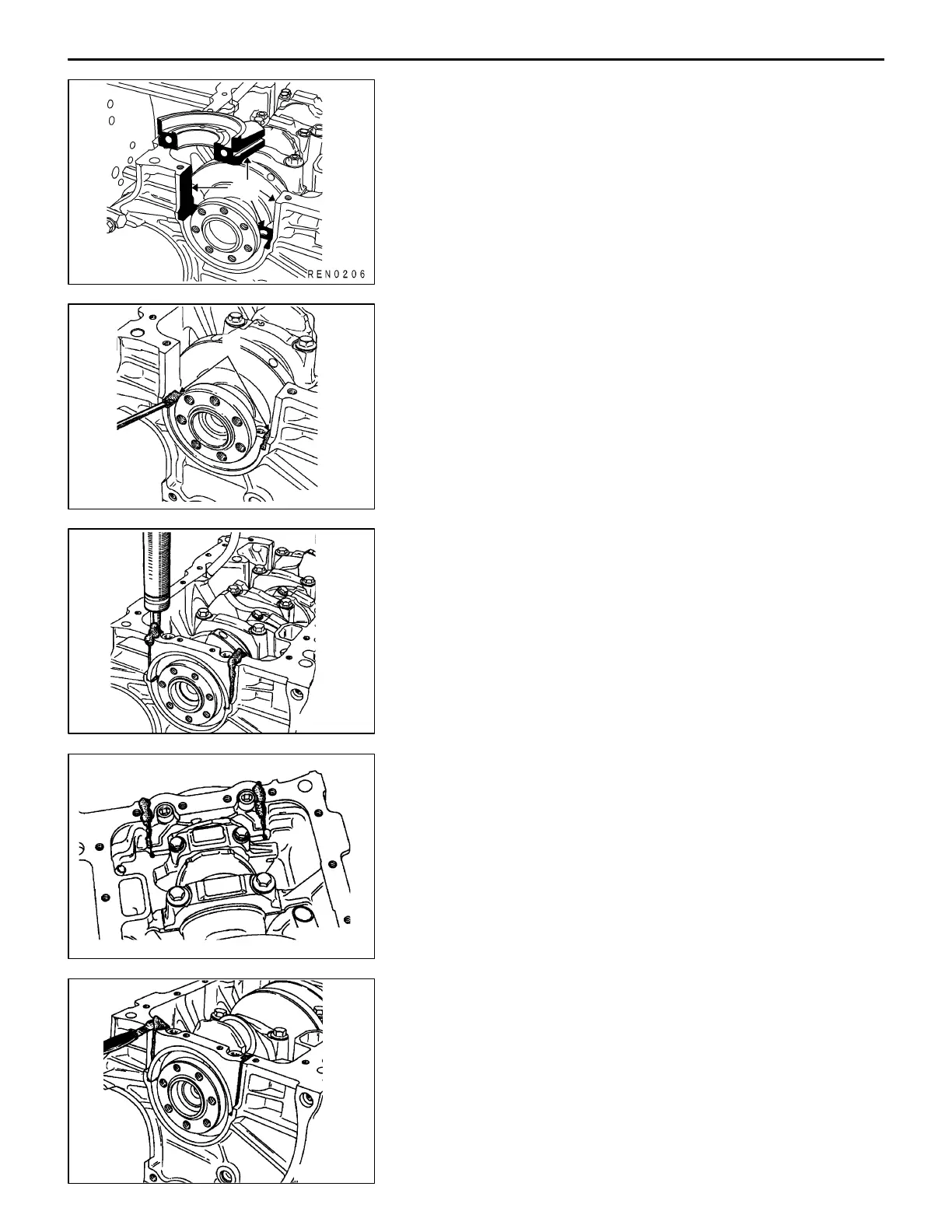

(10)Allow the mixture to ooze out slightly from either side

of the grooves in the crankshaft bearing cap to be sure

that the mixture injected has completely filled the sealing

groove.

(11)Use a cloth to wipe off any excess mixture, both on the

inside and the outside of the cylinder block.

(12)Leave to dry for a few moments then cut the surplus

from the sealing face.

(13)Check that the crankshaft turns freely.

A

PWEE0001-A

E

Mar. 2001Mitsubishi Motors Corporation Revised

REN0207

B

REN0208

REN0209

REN0210

Loading...

Loading...