Do you have a question about the Mitsubishi F9Q and is the answer not in the manual?

Lists standard and limit values for various engine components.

Lists required torque values for various engine fasteners and components.

Specifies torque values for camshaft and vacuum pump related bolts.

Guidance on using special tools for crankshaft pulley removal.

Guidance on using special tools and torque for crankshaft pulley installation.

Detailed steps for timing belt removal, including crankshaft alignment.

Steps for installing the timing belt, including crankshaft timing and pin insertion.

Steps for aligning timing marks on camshaft and crankshaft sprockets with the belt.

Detailed procedure for tensioning the timing belt using a microphone and standard value.

Procedure for final belt tension check and adjustment using MUT-II.

Steps for pressing in valve guides using specific tools and pressure.

Guidance on selecting and installing the correct thickness cylinder head gasket.

Detailed procedure for tightening cylinder head bolts in multiple stages and angles.

Procedures for measuring valve stem diameter, seat angle, and projection.

Steps for checking and adjusting valve clearances.

Detailed measurement of valve clearance for cold engine.

Procedure for selecting tappets based on measured wall thickness for clearance adjustment.

Procedure for fitting the oil pan with a new gasket and tightening bolts.

Steps for installing piston/connecting rod assemblies into the cylinder block.

Procedure for measuring piston protrusion using a dial gauge.

Lists the sequence of parts for removal of the flywheel, oil seals, and bearings.

Procedure for installing bearing caps, tightening bolts, and checking side clearance.

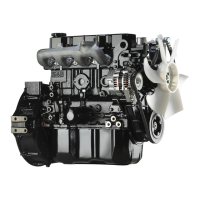

| Engine Code | F9Q |

|---|---|

| Fuel Type | Diesel |

| Aspiration | Turbocharged |

| Cooling System | Water-cooled |

| Displacement | 1.9 L (1870 cc) |

| Bore x Stroke | 80 mm x 93 mm |

Loading...

Loading...