F9Q ENGINE – Cylinder Block

11A-14-2

REMOVAL SERVICE POINT

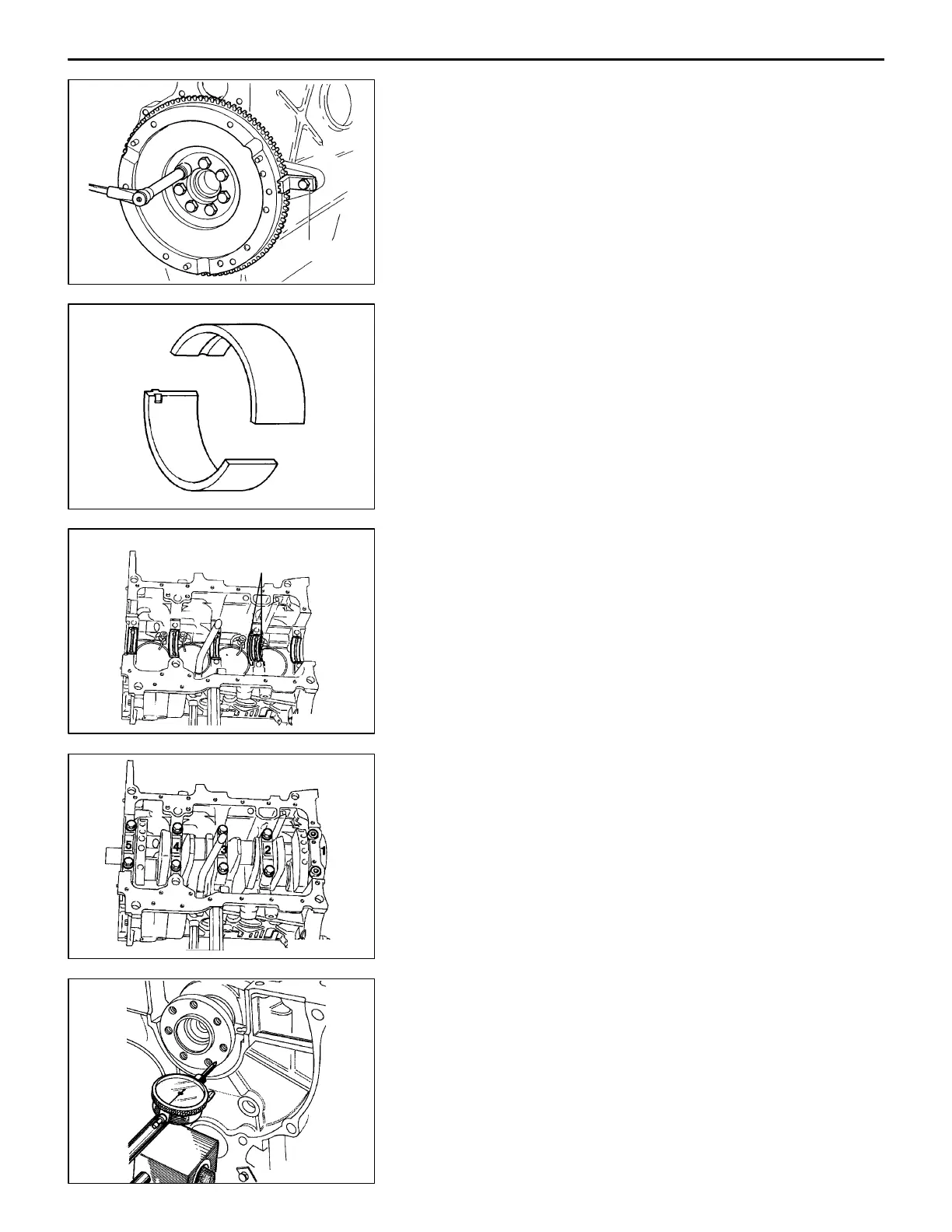

AA" FLYWHEEL REMOVAL

Use special tool MB996015 to hold the flywheel during

removal.

INSTALLATION SERVICE POINTS

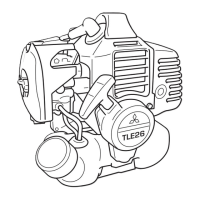

"AA CRANKSHAFT BEARING INSTALLATION

(1) Install the bearings having an oil groove to the cylinder

block.

(2) Install the bearings having no oil groove on the bearing

caps.

(3) Install the thrust bearings at the No. 2 upper bearing

with the grooved side towards the crank web.

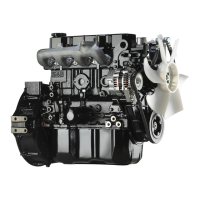

"BA BEARING CAP INSTALLATION

(1) Install the bearing caps No. 3, 4 and 5. Each bearing

cap is provided with a embossed identification number.

Install the bearing caps in the correct positions according

to the identification numbers.

(2) Use engine oil to lubricate the threads and under the

heads of the mounting bolts for the crankshaft bearing

caps. Tighten the bearing cap bolts No.3, 4, 5 to a torque

of 65 Nm. Fit the bearing cap No.2 without torque

tightening the bolts.

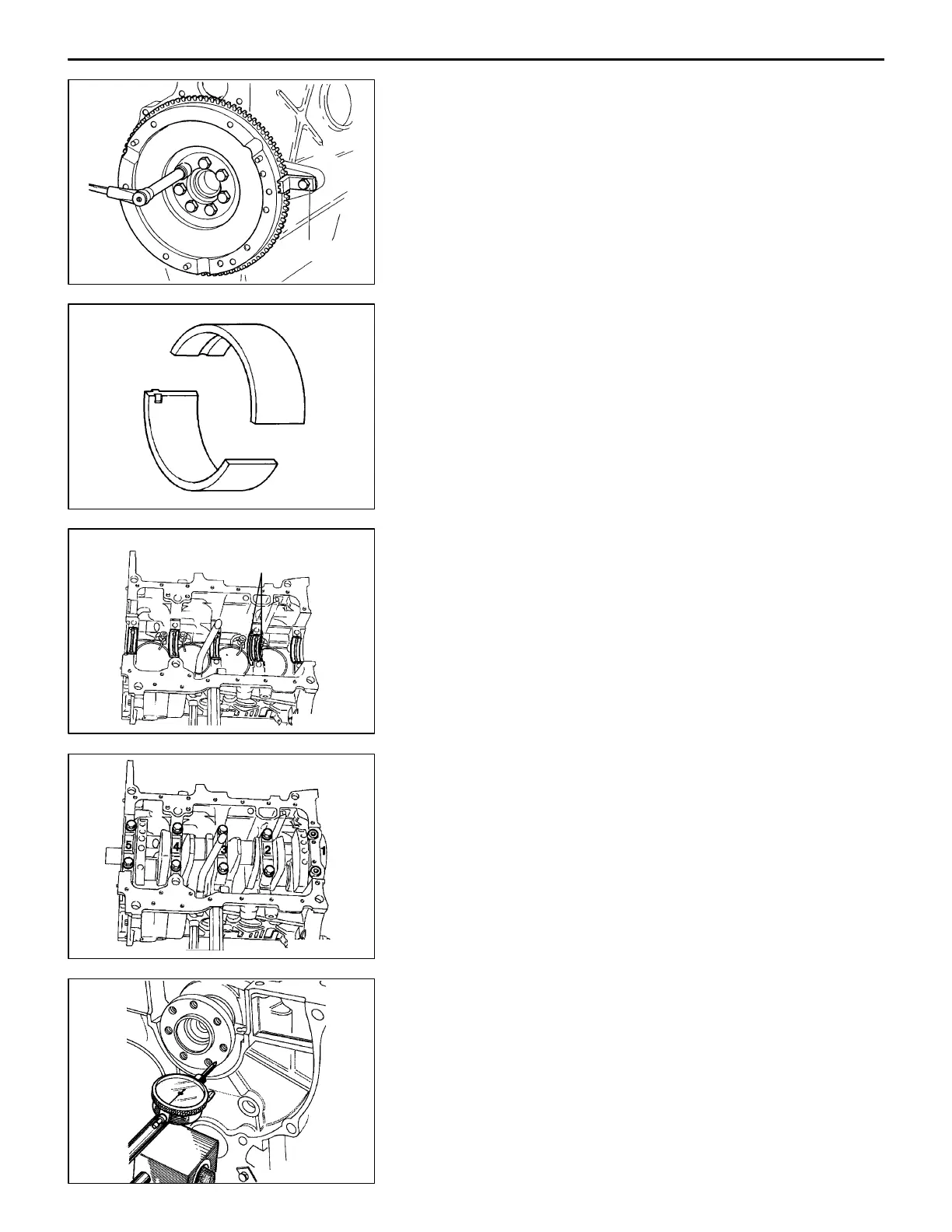

(3) Check the crankshaft side clearance.

Standard value: 0.07 – 0.23 mm

NOTE

If the measurement is out of specification, adjust by thrust

bearing. Four sizes of thrust bearings are available: 2.30,

2.35, 2.40 and 2.45 mm.

(4) Tighten the bolts of the bearing cap No. 2 to a torque

of 65 Nm.

REN0147

MB996015

PWEE0001-A

E

Mar. 2001Mitsubishi Motors Corporation Revised

REN0211

REN0203

Thrust bearing

REN0204

REN0205

Loading...

Loading...