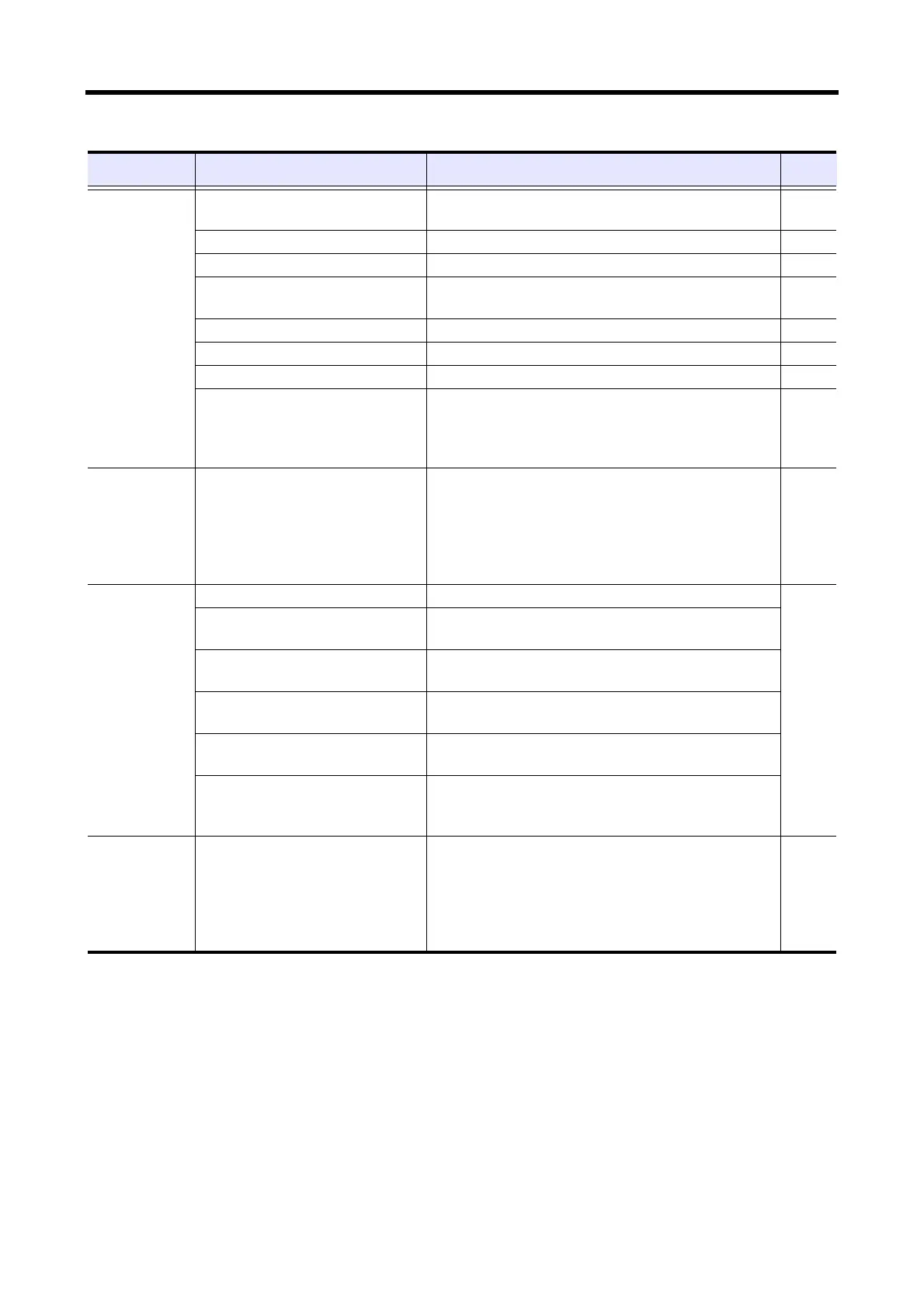

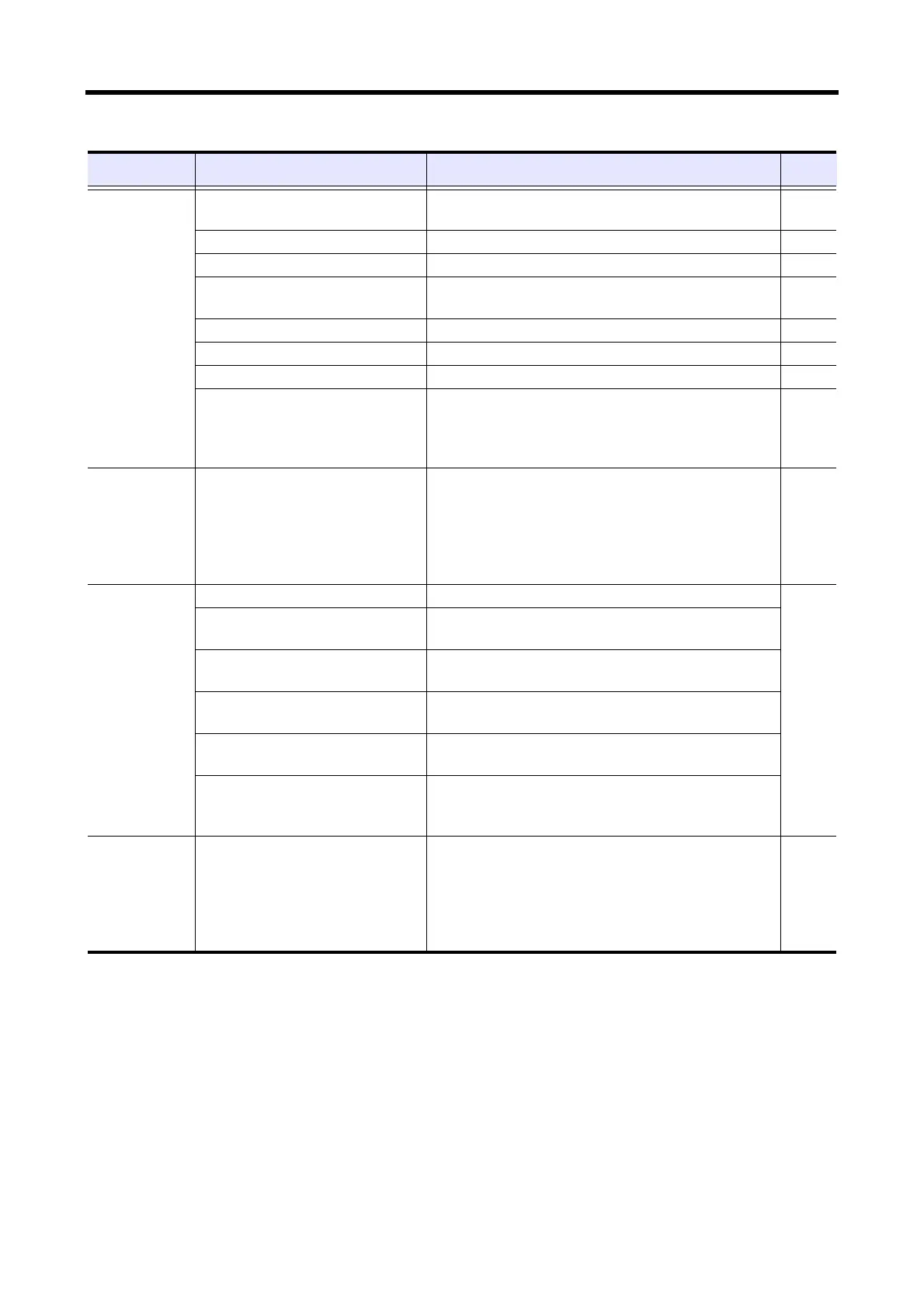

Chapter 5 PERIODIC MAINTENANCE CHART

5-4

Every 3000

service

hours

Valve clearance

Inspect and adjust (also inspect inside of rocker

chamber).

½

Fuel injection nozzles Change nozzle tipes and adjust pressure. ½

Fuel filters (wire-element) Disassemble and clean inside. 6-1

Breather

Inspect and clean mist separator, and change

expendable parts.

½

Governor oil filter Change. ½

Pre-cleaner Change. 6-17

Air cleaner element Change. 6-18

Magnetic pickup

Inspect clearance with the flywheel, attachment

of foreign items on the tip, mounting nut tight-

ness, an open-circuit and connector disconnec-

tion.

½

After 3000

services

hours or 2

years,

whichever

comes first

Fuel system accumulator Refill with nitrogen gas. ½

Every 6000

service

hours

Camshafts and tappets Inspect. ½

Crankcase

Inspect inside (remove the side cover for inspec-

tion).

Water pump

Change oil seals, unit seals and other expend-

able parts.

Damper

Check temperature with thermo label and check

for silicon oil leakage.

Turbocharger

Inspection of shaft and wheel smooth rotation

and thrust for looseness.

Inspection of pipe clamps of

fuel lines, oil lines, instrument

pipes and starting air pipes

Inspection of interference and wear, and repair

rubber tape.

After 12000

service

hours or 2

years,

whichever

comes first

Coolant Change.

6-13

Table 5-1 Periodic maintenance chart for engine in regular use (2 / 5)

Service

interval

Service item Service contents Page

Loading...

Loading...