Chapter 6 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES

6-15

Pouring coolant

1 Make sure the drain cocks on the engine and

water pump are closed firmly.

2 Remove the cap from the water supply inlet of the

coolant tank, and pour undiluted LLC.

Note:(a) Determine the amounts of LLC and water to

be poured by using the LLC concentration

chart.

(b) Regarding coolant, refer to "Coolant" (4-6).

3 Pour soft water with minimal impurities slowly to

the full level.

4 When coolant reaches the full level securely, close

the water supply inlet cap of the coolant tank.

5 To release air from the water pump and coolant

pipes, pull the manual stop lever fully to the STOP

position and hold it in that position to keep the fuel

injection pump in no-injection condition, then sup-

ply starting air and crank the engine for about 10

seconds.

6 Wait for about 1 minute, then repeat the above

cranking operation twice to remove air from the

water pump.

7 Check the level gage on the coolant tank to make

sure there is sufficient coolant (surface level at

about the center of the level gage). If the coolant

level is low, add coolant.

8 Start the engine, and operate it under light load

until the thermostat opens the valve to allow soft

water and LLC to mix thoroughly.

9 Stop the engine, check the level gage on the cool-

ant tank. If the coolant level is low, add coolant to

the center of the fluid level gage.

Note: Always add coolant having the same LLC con-

centration.

10 Check the pipe joint and other parts for coolant

leaks.

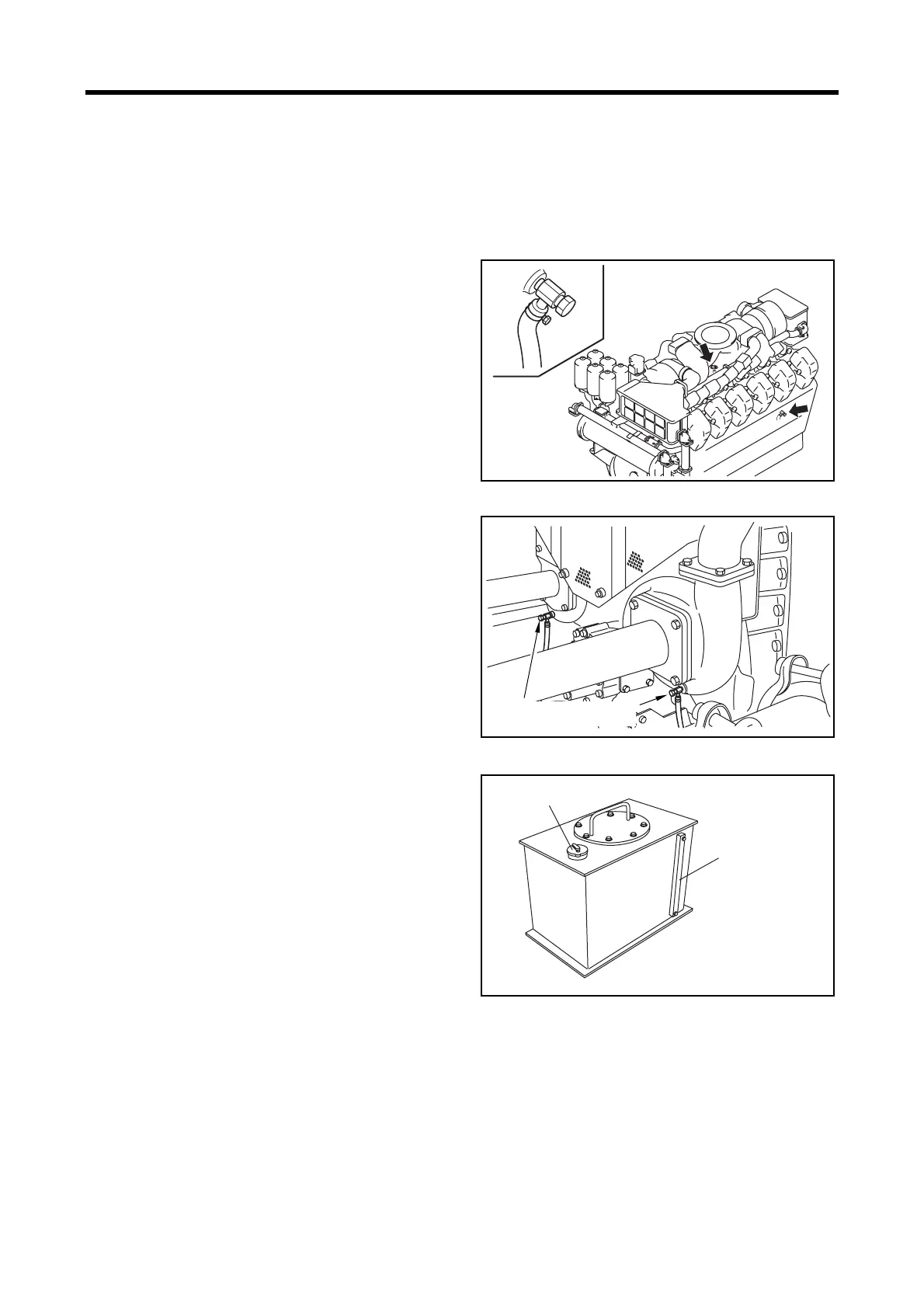

fig.6-25 Coolant drain cock on the engine

fig.6-26 Coolant drain cock on the water pump

Coolant drain cocks

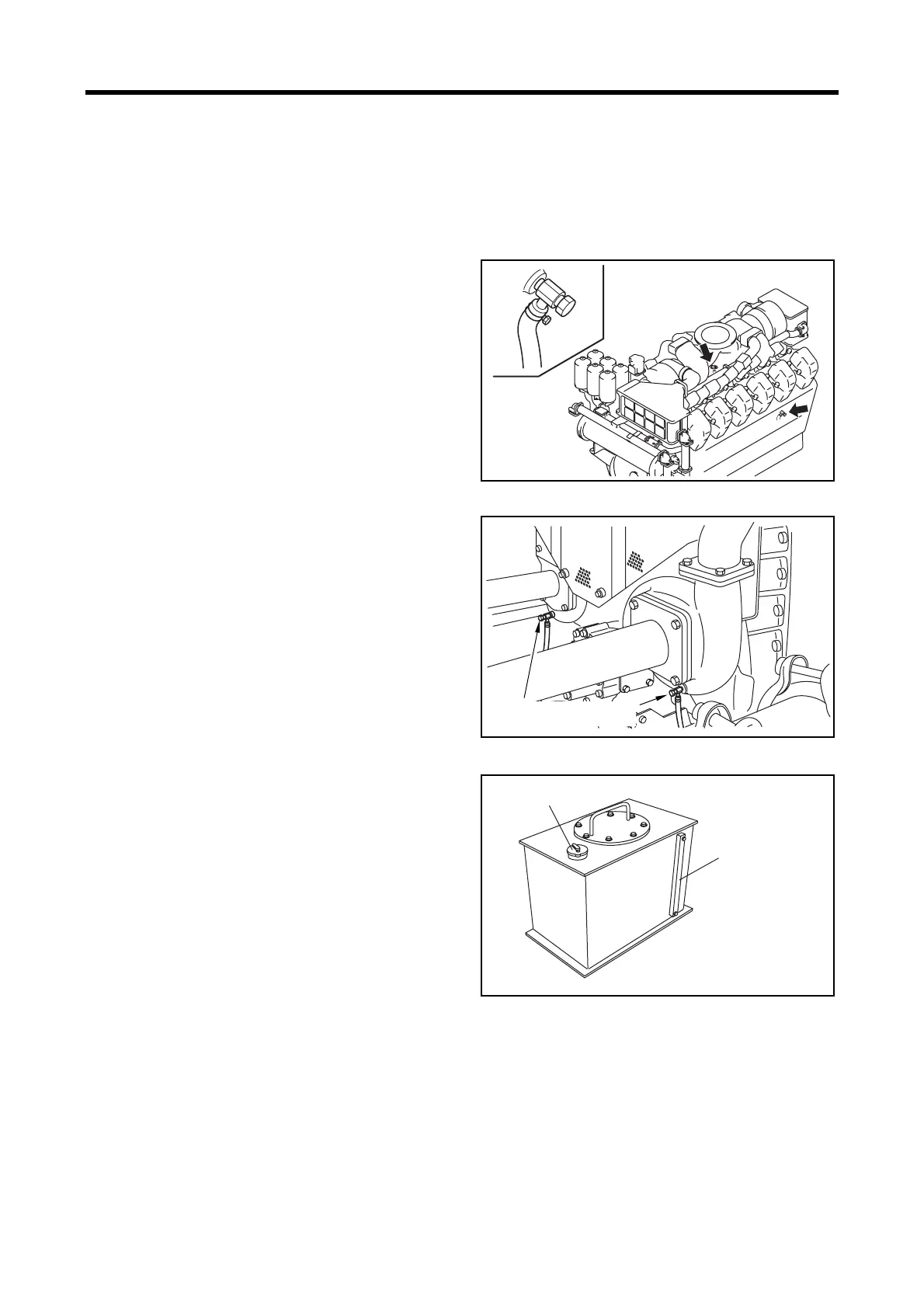

fig.6-27 Water tank coolant level

Water supply inlet

Fluid level gage

Coolant capacity (engine only)

S12U: approx. 520 L [137.37 U. S. gal]

S16U: approx. 700 L [184.92 U. S. gal]

Loading...

Loading...