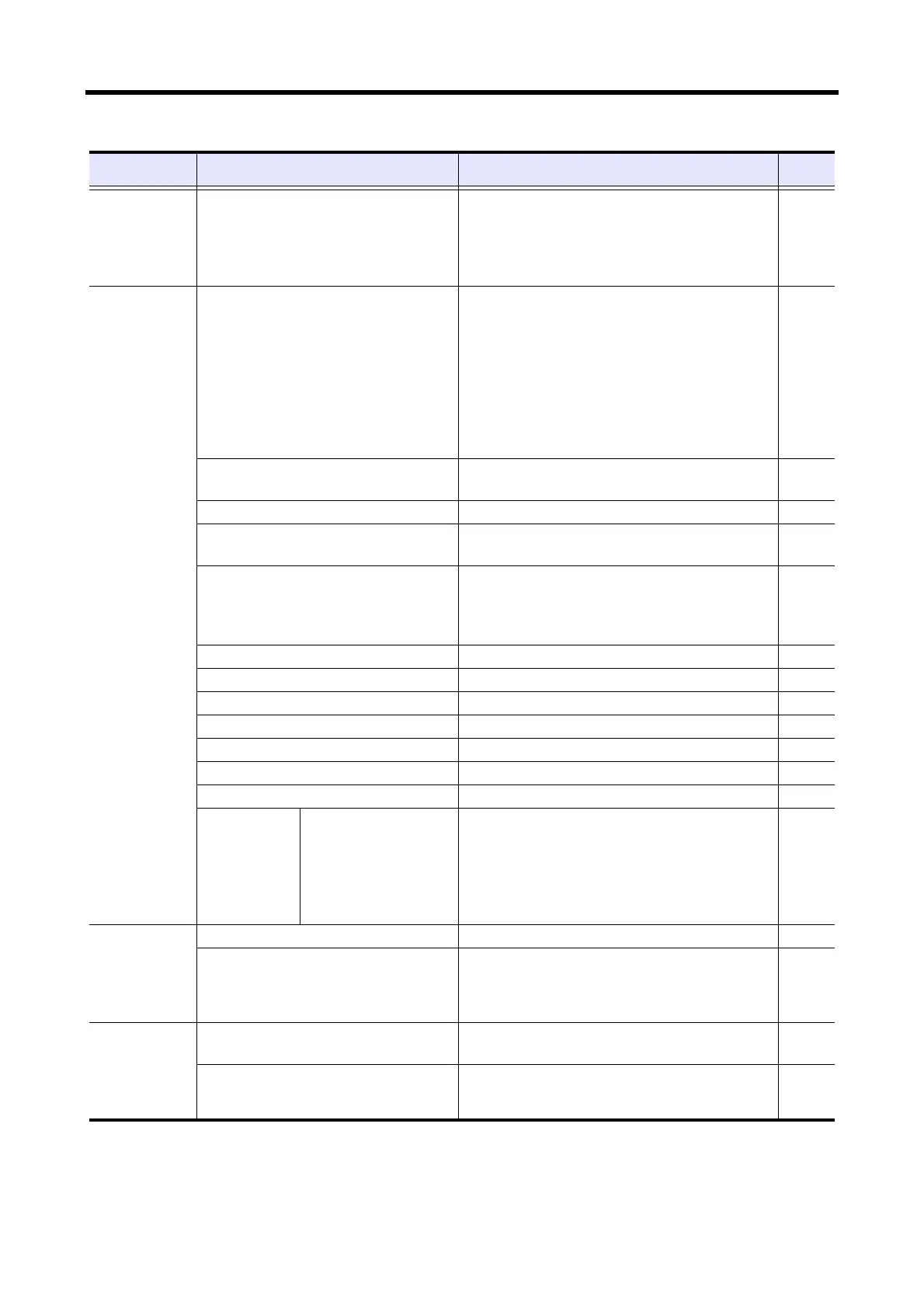

Chapter 5 PERIODIC MAINTENANCE CHART

5-9

After 1 year

or 500 ser-

vice hours,

whichever

comes first

Engine oil

Analyze engine oil properties.

(according to engine oil analysis service)

6-12

Every year

Conducting maintenance operation

Operate the engine under no load for 2

hours (more than 1/2 load).

Inspect starting property, exhaust color,

abnormal vibrations, abnormal sounds and

abnormal odors.

Inspect displayed value of each gage (such

as oil pressure gage, water temperature

gage, oil temperature gage, exhaust tem-

perature and rotating speed gage).

3-13

Valve clearance

Inspect and adjust (also inspect inside of

rocker chamber).

½

Camshaft and tappets Inspect. ½

Damper

Check temperature with thermo label and

check for silicon oil leakage.

½

Magnetic pickup

Inspect clearance with the flywheel, attach-

ment of foreign items on the tip, mounting

nut tightness, an open-circuit and connector

disconnection.

½

Fuel tank Drain water. 6-2

Fuel injection nozzles Change nozzle tips and adjust pressure. ½

Fuel injection timing Inspect and adjust. ½

Coolant Inspect LLC concentration. 6-13

Exhaust pipes and exhaust muffler Inspect and drain water. 6-16

Pre-cleaner Clean. 6-16

Air cleaner element Clean and inspect. 6-17

Protection

device

Increasing coolant

temperature,

decreasing oil pres-

sure, overspeed

and emergency

stop device

Inspect operation.

½

After 2 years

or 500 ser-

vice hours,

whichever

comes first

Engine oil Change.

6-7

Oil filter and bypass oil filter Change. 6-7

After 2 years

or 1500 ser

-

vice hours,

whichever

comes first

Fuel filters

(center-bolt and cartridge)

Change.

6-3

Fuel filter (wire-element) Clean inside. 6-2

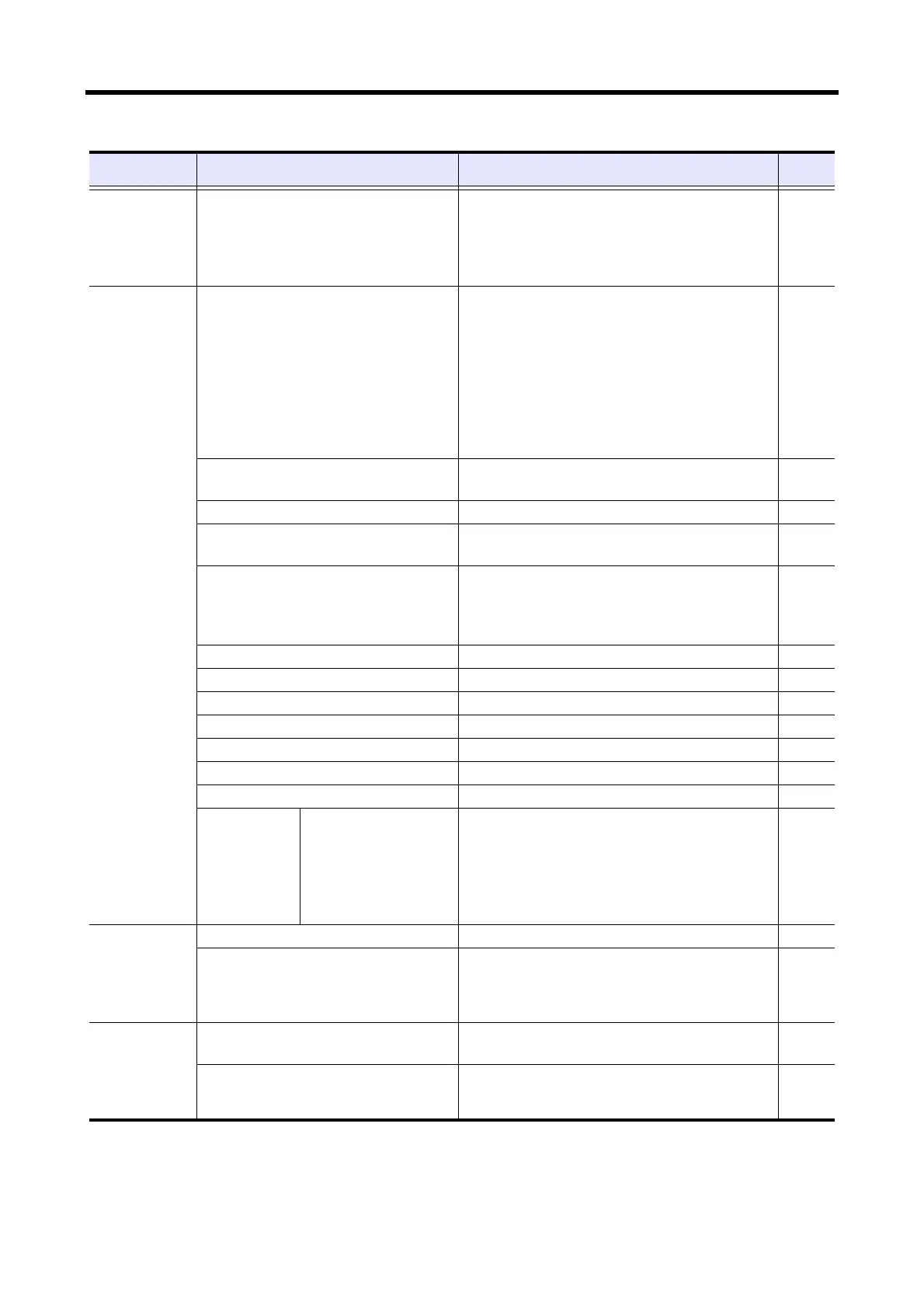

Table 5-2 Periodic maintenance chart for emergency engine (2 / 5)

Service

interval

Service item Service contents Page

Loading...

Loading...