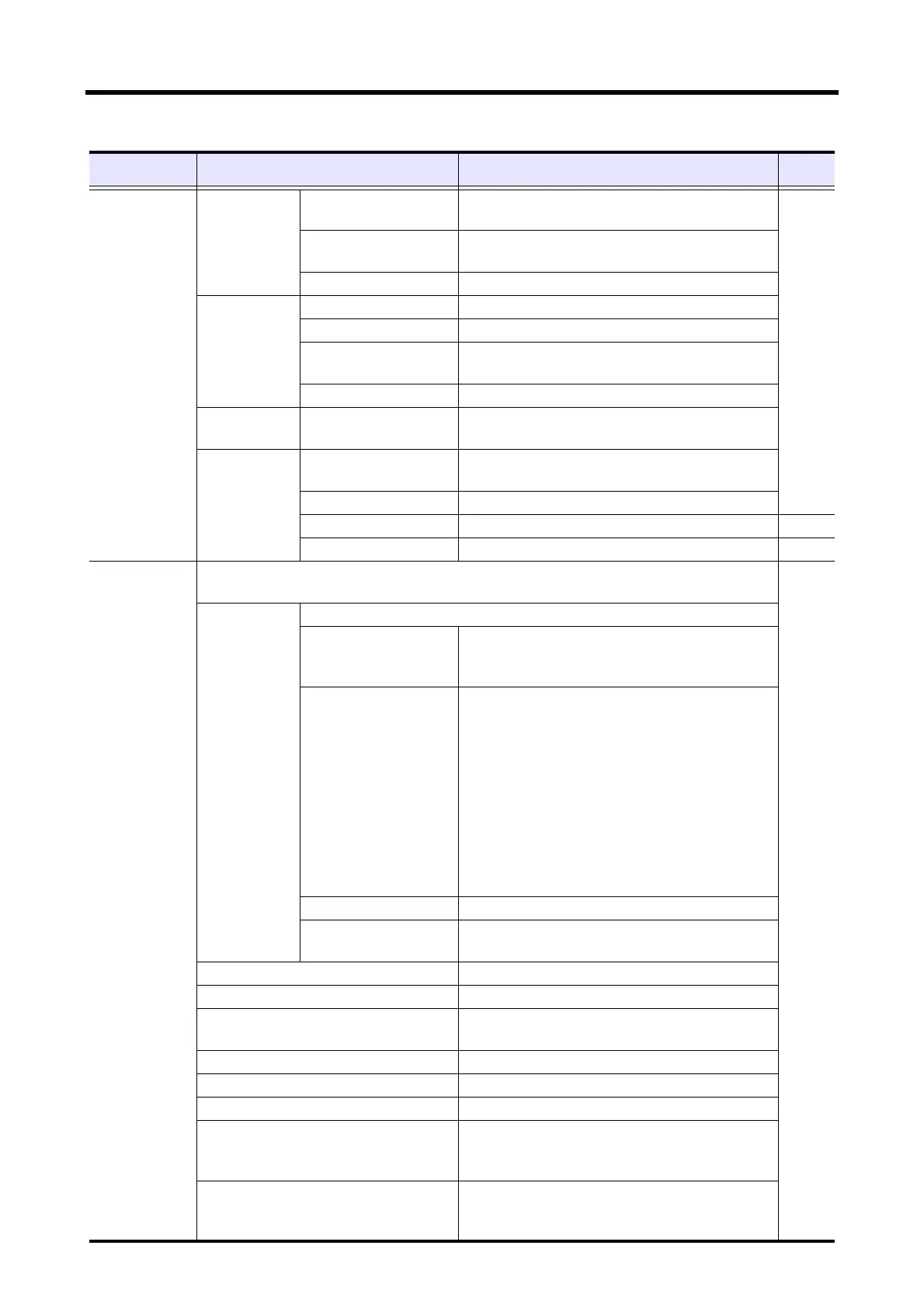

Chapter 5 PERIODIC MAINTENANCE CHART

5-11

Every 4

years

Fuel system

Fuel injection

nozzles

Change nozzle tips and adjust pressure.

½

Fuel injection pump

Disassemble, maintain, adjust and change

O-rings.

Fuel tank Clean inside.

Lubricating

system

Oil pump Inspect discoloration and external.

Oil cooler Inspect and clean element.

Breather

Clean mist separator and change expend-

able parts.

Governor oil filter Change.

Cooling

system

Coolant thermostat Change.

Inlet and

exhaust

systems

Turbocharger

Remove carbons, change seal rings and

change expendable parts.

Air cooler Disassemble and clean element.

Pre-cleaner Change.

6-16

Air cleaner element Change. 6-17

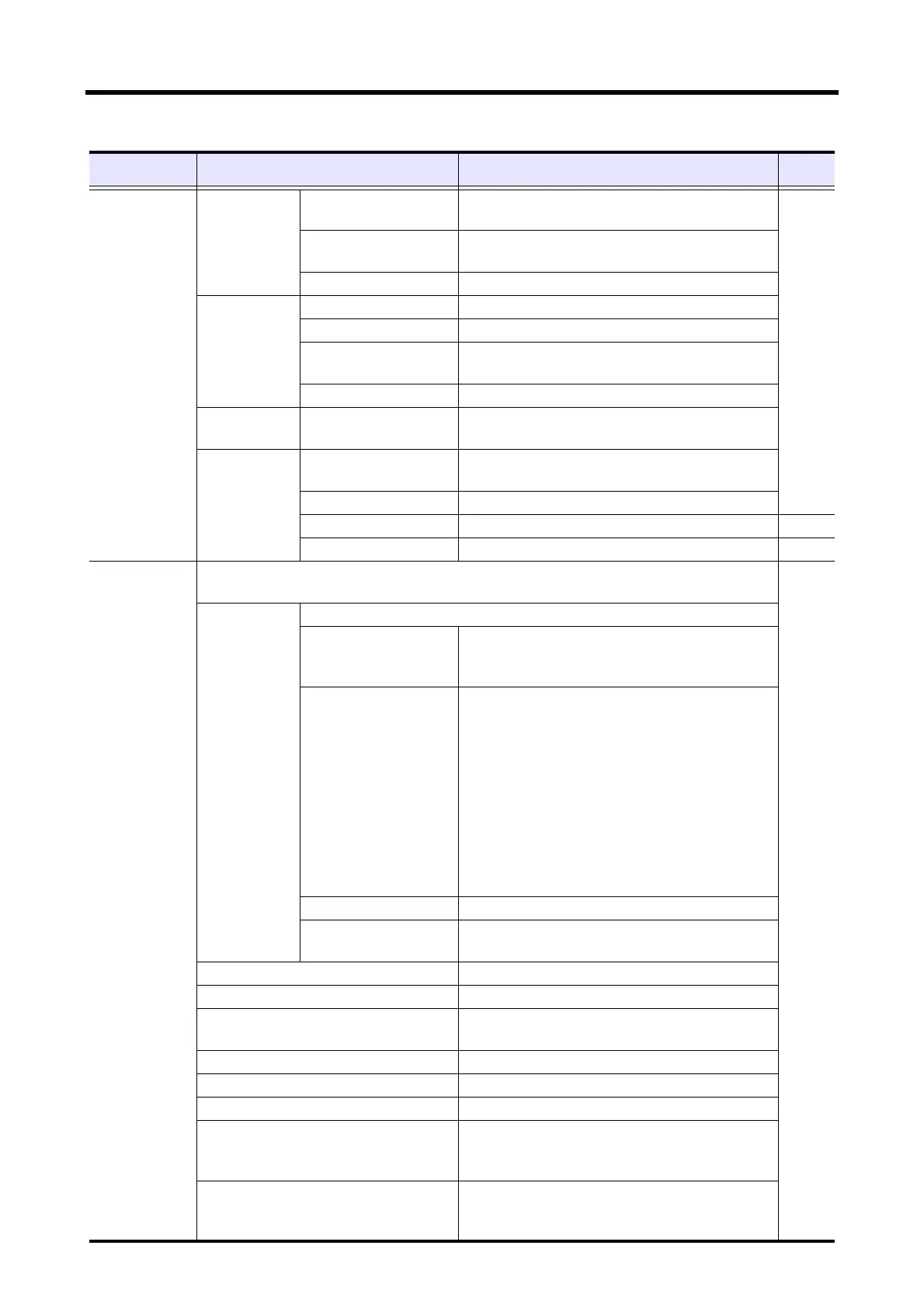

Every 8

years

Major overhaul (complete disassembly and inspection)

Change all O-rings, gaskets and seals.

½

Cylinder

heads and

valve mech-

anisms

Disassemble and maintain, clean and change expendable parts.

Inlet and exhaust

valves and valve

seats

Inspect, regrind and lap.

Valve guides, valve

rotators, valve cot-

ters, pushrods,

rocker arm bush-

ings, valve springs,

tappet rollers, tap-

pet roller bushings,

tappet shafts, tap-

pet guides and tap-

pet guide set

screws

Inspect.

Stem seal Change.

Copper tubes and

copper tube O-rings

Change.

Safety valves Inspect and change expendable parts.

Cylinder liners Inspect, clean and change O-rings.

Main bearings

Inspect main bearing caps, bolts and main

bearings, and inspect thrust plate.

Cam bushings Inspect.

Pistons Inspect including overhaul and clean.

Piston rings Change.

Connecting rods

Inspect bolts, inspect Magnaflux serrations,

change big-end bearing shells and inspect

small-end bushings.

Front gear and timing gear

Inspect gear teeth, bearings and shafts.

Change front seal, rear seal, front gear

case gasket and rear gear case gasket.

Table 5-2 Periodic maintenance chart for emergency engine (4 / 5)

Service

interval

Service item Service contents Page

Loading...

Loading...