14

5-564

➅ Air Flow Proving Switch

The air flow proving switch is factory installed in the duct furnace

electrical junction box. The air flow proving switch monitors the

pressure differential between the duct furnace and the atmosphere.

The purpose of the air flow proving switch is to cut power to the

gas controls if a positive pressure is not measured by the switch.

This could be caused by a lack of air movement through the heat

exchanger.

NOTE: The air flow proving switch will prevent any heat

exchanger warm-up (the unit should not be equipped with

a time delay relay) because the gas controls can not be

energized until air flow is proven.

Setting the Air Flow Proving Switch

The range of the air flow proving switch is adjustable between 0.17"

to 5.0" W.C.

1. Set the thermostat so that there is a call for heat. This should fire

the burner and the blower should start.

2. Turn the set screw of the pressure switch clockwise until it stops.

This will set the pressure at 5.0" W.C.

3. Turn the screw counter-clockwise until the gas controls light and

then one additional full turn (This is approximately 0.25'' W.C.).

This will allow for dirty filters or any other slight static pressure

increases in the system.

➆ Manual Reset High Limit

The manual reset high limit switch is factory installed in place

of the standard automatic reset high limit switch located in the

duct furnace electrical junction box. In case of a failure of the

blower motor, blockage of the inlet air, etc., the manual reset

switch prevents the unit from cycling on the high limit. If the limit

temperature is exceeded, a service person must inspect the unit for

the cause of the high discharge temperature, take corrective action,

and then reset the switch.

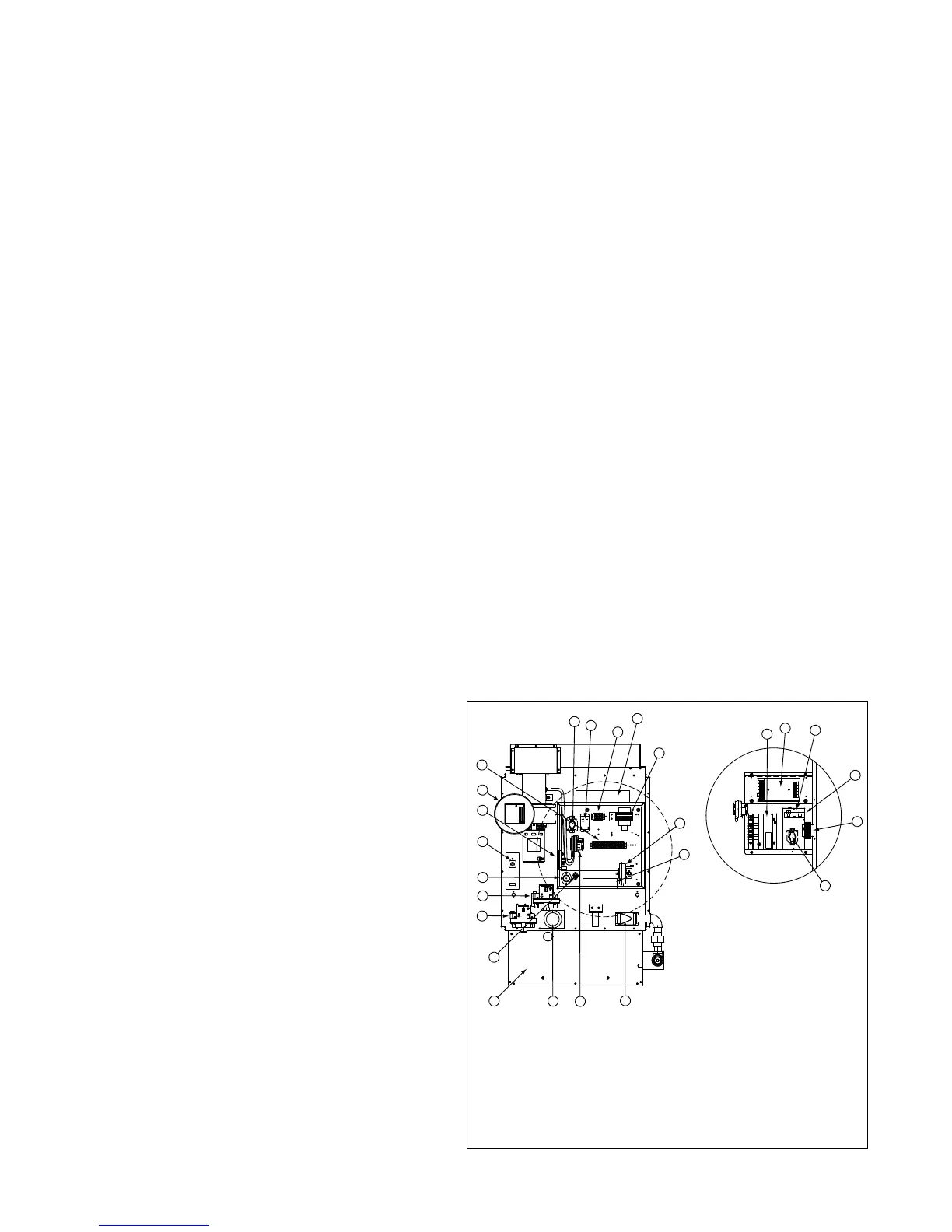

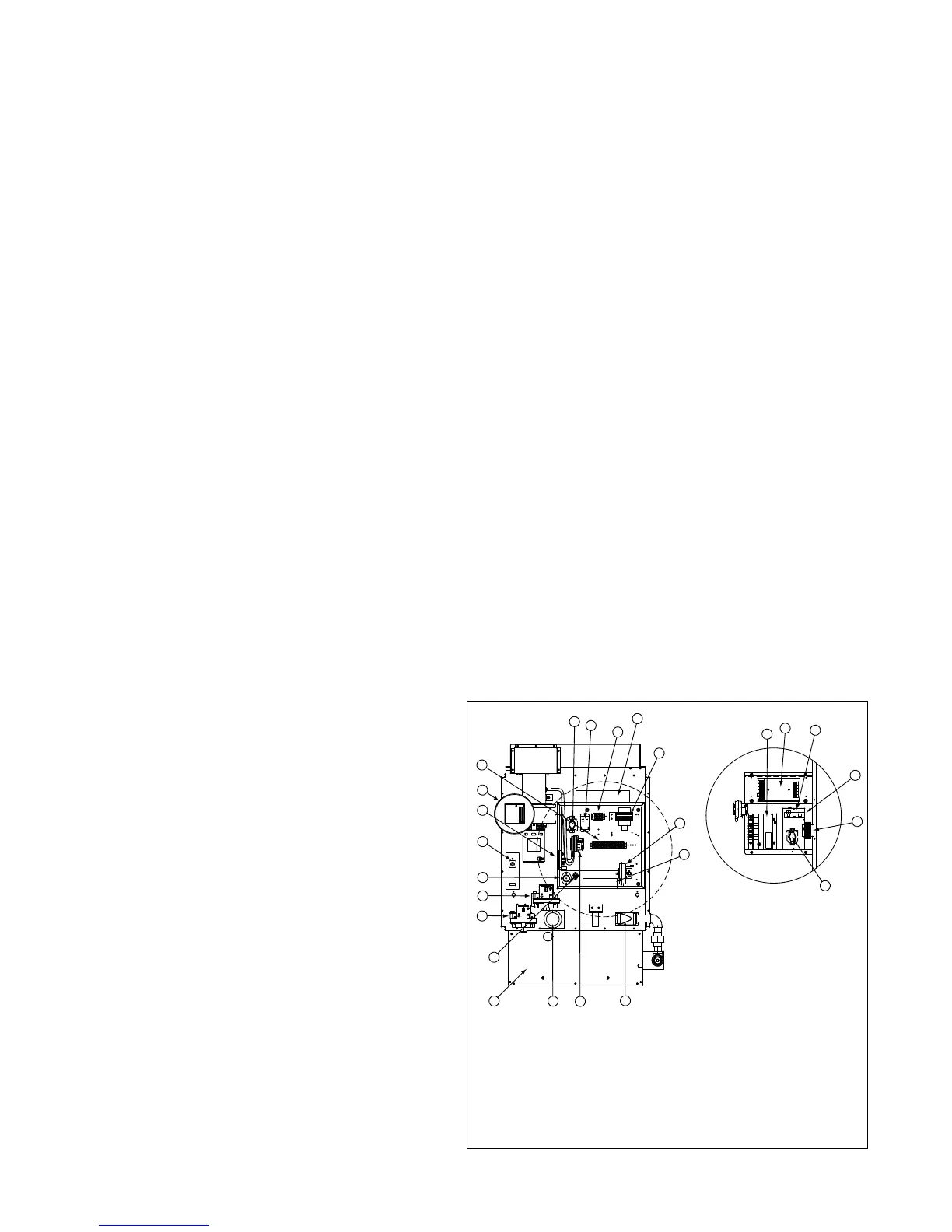

Figure 14.1 - Location of Gas Control Options

Gas Control Options

The unit must be reviewed to determine if any of the listed gas

control options were supplied.

➀ Time Delay Relay

The Time Delay Relay is factory installed in the duct furnace

electrical junction box. The standard duct furnace is provided

for instantaneous fan operation. On a call for heat, the blower is

energized at the same time as the gas controls. The optional time

delay relay allows the gas controls to operate for approximately 30

seconds before the blower starts. This allows the heat exchanger

a warm up period so that the initial delivered air coming out of the

ductwork is not cool. The time delay relay also keeps the motor

running for approximately 30 seconds after the call for heat has

been satisfied to remove the residual heat from the heat exchanger.

➁ Low Gas Pressure Switch

The low gas pressure switch is factory installed in the duct furnace

above the gas train. The switch monitors the gas pressure upstream

of all the gas controls and shuts off the electric supply to the

ignition controller and combination gas valve if low gas pressure is

experienced. This will shut off all gas flow to the burner. The switch

has an automatic reset so that if the gas pressure is interrupted

and then is returned, the switch will automatically allow the unit to

operate when gas conditions are returned to the allowable range

of the pressure switch. The pressure switch range is 2" to 14" W.C.

and should be set to insure that the minimum inlet gas pressure is

available (6" W.C. for natural gas, 11" W.C. for propane gas).

➂ High Gas Pressure Switch

The high gas pressure switch is factory installed in the duct

furnace above the gas train. The switch monitors the gas pressure

downstream of all the gas controls and shuts off the electric supply

to the ignition controller and combination gas valve if high gas

pressure is experienced right before the manifold. This will shut off

all gas flow to the burner. The switch has a manual reset so that if

the gas pressure is too high, a service person must check the unit

to make sure that none of the gas controls have been damaged

by the high gas pressure and then reset the switch to allow the

unit to operate when gas conditions are returned to the allowable

range of the pressure switch. The pressure switch range is 2" to 16"

W.C. and should be set to insure that the maximum manifold gas

pressure is not exceeded (3.5" W.C. for natural gas, 10" W.C. for

propane gas).

➃ Supply Air Fire Stat

The fire stat is factory installed in the duct furnace electrical junction

box with the sensor in the discharge air stream. In case of elevated

temperatures in the supply air, the manual reset switch shuts

down the entire unit. If the limit temperature is exceeded, a service

person must inspect the unit for the cause of the high discharge

temperature, take corrective action, and then reset the switch.

➄ Timed Freeze Protection

The timed freeze protection system is factory installed in the duct

furnace electrical junction box with the sensor (30°-75°F adjustable)

factory installed in discharge air stream. On initial start-up, the

timed delay in the system allows the unit to go through the normal

ignition sequence. The timed delay is an automatic reset switch and

adjustable for 1-10 minutes. In the event that the unit fails to fire

after this period, the discharge air sensor will sense the cold air and

will shut down the entire unit.

OPTIONS

Units with Standard

Control Panel

Units with Premium Control Box

13

48

6

46

6

8

57

9

13

49

2

3

50

5

4

1

10

9

8

12

46

47

55

51

52

12

300

FM

R

LISTED

PRESSURE

OPERATED

SWITCH

504H

ADDISON

IL. U.S.A.

MODEL

RLGP-A

M1

LOW

PRESSURE

50

100

150

200

350

250

mm.

W.C.

2

4

6

8

10

14

IN.

12

300

FM

R

LISTED

PRESSURE

OPERATED

SWITCH

504H

ADDISON

IL. U.S.A.

MODEL

RLGP-A

M1

LOW

PRESSURE

50

100

150

200

350

250

mm.

W.C.

2

4

6

8

10

14

IN.

12

3

456

A1010 Amplifier

89101114

GH

T

PV

MV

LED

TH

PV/MV

GND

TR

SENSE

1. Discharge Thermostat

2. Low Gas Pressure Switch

3. High Gas Pressure Switch

4. Power Exhauster

5. Timed Freeze Protection

6. Ignition Controller

8. Control Relay

9. Time Delay Relay

10. Furnace Low Voltage Terminal Strip

12. Furnace Supply Power Terminal Strip

Note: Wrap around gas train on

premium and electronic

modulation units only.

13. Control Step Down Transformer

46. Electronic Modulating Amplifier

47. Electronic Modulating Gas Valve

48. Air Flow Proving Switch

49. High Limit Switch

50. Supply Air Fire Stat

51. Main Gas Valve

52. Burner Box

55. Differential Pressure Switch

57. Control Terminal Board

Loading...

Loading...