Do you have a question about the Mondolfo Ferro As933 and is the answer not in the manual?

Details conditions and methods for transporting, storing, and handling the tyre changer.

Specifies the width, depth, height, and weight of the machine's packaging for transport.

Defines the acceptable temperature range for storing and transporting the machine.

Provides instructions for safely unpacking and assembling the tyre changer.

Explains how to lift and move the machine from its pallet safely.

Details necessary space, floor load, and ambient conditions for correct installation.

Covers procedures and requirements for connecting the machine to electrical and air supplies.

Outlines essential safety rules and precautions for operating the equipment.

Defines essential skills, knowledge, and responsibilities for safe machine operation.

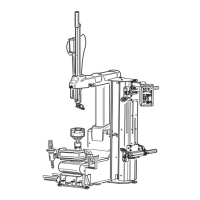

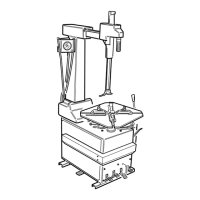

Provides a general overview of the tyre changers' design and how they operate.

Explains the significance of safety decals and how to obtain replacements.

Details clamping capacity, rim width, tyre diameter, and tyre width.

Covers bead breaker opening, pressure, air pressure, weight, and noise level.

Lists available optional accessories for enhancing machine functionality.

Defines the intended use and limitations of the tyre changers.

Details the steps to stop the machine in an emergency situation.

Details the function and operation of various pedals, knobs, and buttons.

Describes the heads, arms, tools, and shoes used for tyre manipulation.

Explains the main structural parts like the tower, slide, table, and clamps.

Covers pressure gauges, regulators, tanks, and other supporting parts.

Details warnings related to crushing hazards between machine parts.

Warns about proper hand placement during clamping and head lowering.

Advises against standing behind the machine during operation.

Alerts to high noise levels during bead breaking and recommends hearing protection.

Explains how to identify the correct side of the wheel for tyre demounting.

Provides specific precautions for handling alloy, European-style, and low-pressure indicator wheels.

Details the steps for performing bead breaking, including positioning and pedal use.

Emphasizes lubrication and checking tyre condition before mounting.

Details the process of placing the tyre, using the head, and rotating the table.

Highlights dangers of tyre inflation and mandatory safety gear.

Details the inflation process for specific models using the pedal and gauge.

Details the inflation process for specific models using the inflation gun.

Provides specific instructions for inflating tubeless tyres on T.I. versions.

Addresses table top rotation faults and pedals not returning to home position.

Covers air leaks from various components and lubricator problems.

Details issues like lack of force or air leaks from the bead breaker cylinder.

Covers table top operation, vertical slide lift, and limit stop malfunctions.

Addresses tower tilt faults, air leaks, and speed regulation problems.

Details pressure gauge issues and guidance from the spare parts handbook.

Covers warnings on non-original parts, pressure tampering, and component modifications.

Details maintenance for the filter, regulator, lubricator, and lubricant flow rate.

Explains condensation water drainage and safe cleaning practices for the machine.

Warns about hazardous substances and the need for proper product disposal.

Instructs on separating electrical waste, recycling, and resource conservation.

Instructs on correct disposal of used oil and cleanup of spills.

Outlines precautions for skin contact, mist, and recommends protective gear.

Provides first aid procedures for ingestion, inhalation, eye, and skin contact with mineral oil.

Presents guidelines and a table for selecting appropriate fire extinguishers.

Explains terms such as air release valve, bead, bead breaking, bead seating, tubeless, and T.I.

Provides a diagram and list of the machine's general electrical wiring components.

Provides a diagram and list of the machine's compressed air system components.

| Manufacturer | Mondolfo Ferro |

|---|---|

| Model | AS933 |

| Category | Tyre Changers |

| Rim Diameter Range | 10-24 inches |

| Rim Width Range | 3"-15" |

| Air Pressure | 8 bar |