MONITOR

HEATING

SYSTEMS

Section

5:

Servicing

3.

Turn

counter-clockwise to remove combustion

ring.

If

ring does not turn, pull up slightly to

loosen retaining clips.

4.

Use wire brush to clean inside of combustion

chamber.

Vacuum and wipe clean with

a

waste cloth.

5.

If tar is present on

the

bumer bottom, remove

the tar by using

a

flat-bladed screw driver or

wire

brush.then clean the area by using

a

vacuum cleaner etc.

NOTE:

Make sure all air inlet openings are clear.

6.

When cleaning the inside of me bumer pot,

remove

the

igniter and change the burner cloth

by the following procebure.

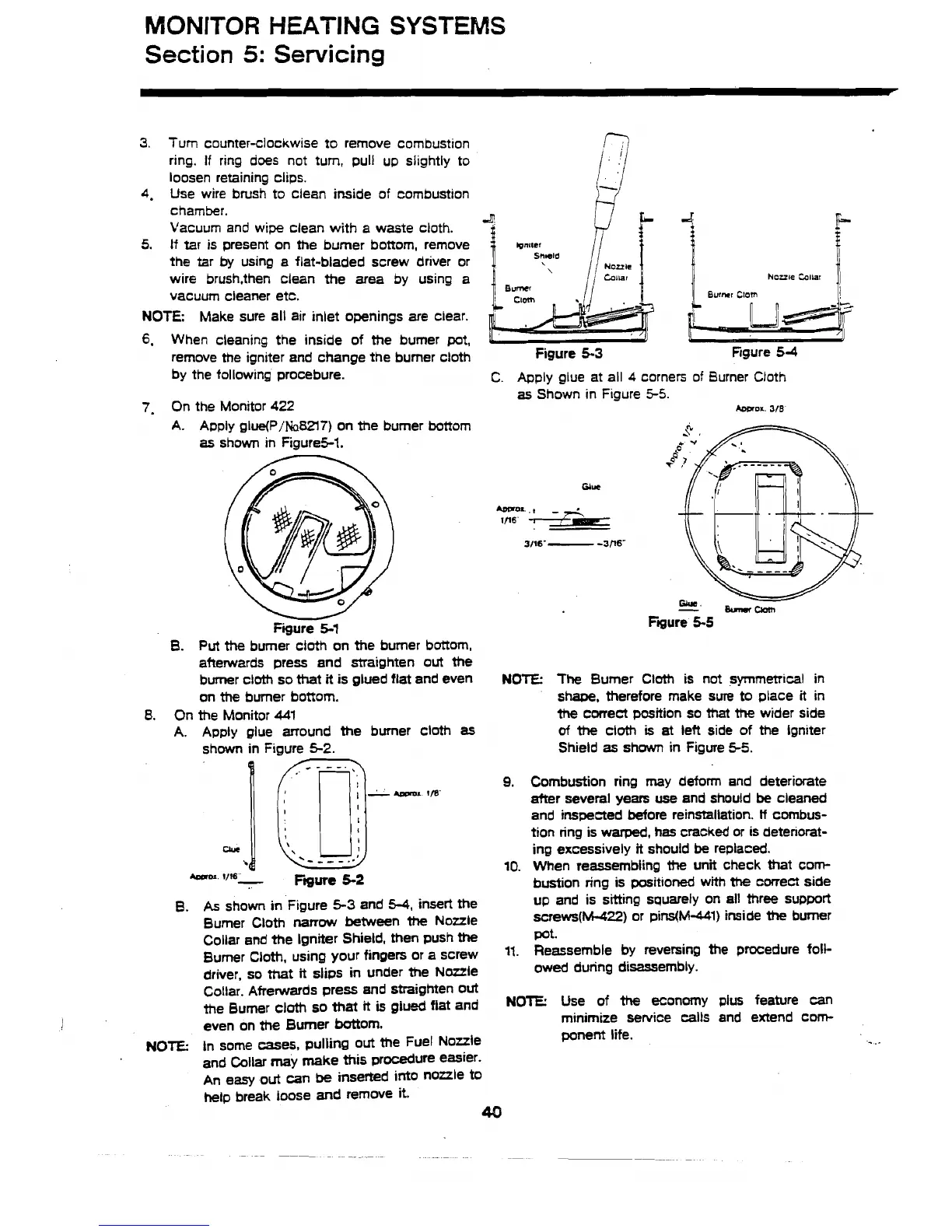

7.

On the Monitor

422

A.

Apply glue(P/Na&lT) on the burner bottom

as

shown in Figure5-1.

u

Figure

5-1

B.

Put

the burner cloth on the burner bottom,

afterwards press and straighten

out

the

burner cloth so that

it

is glued flat and even

on the burner bottom.

8.

On the Monitor

44l

A.

Apply glue arround

the

burner cloth

as

shown in Figure

5-2.

1

[jy-'m

I

Oue

\

.

b

--___..'

*OePl

'Is-

Ftgure

5-2

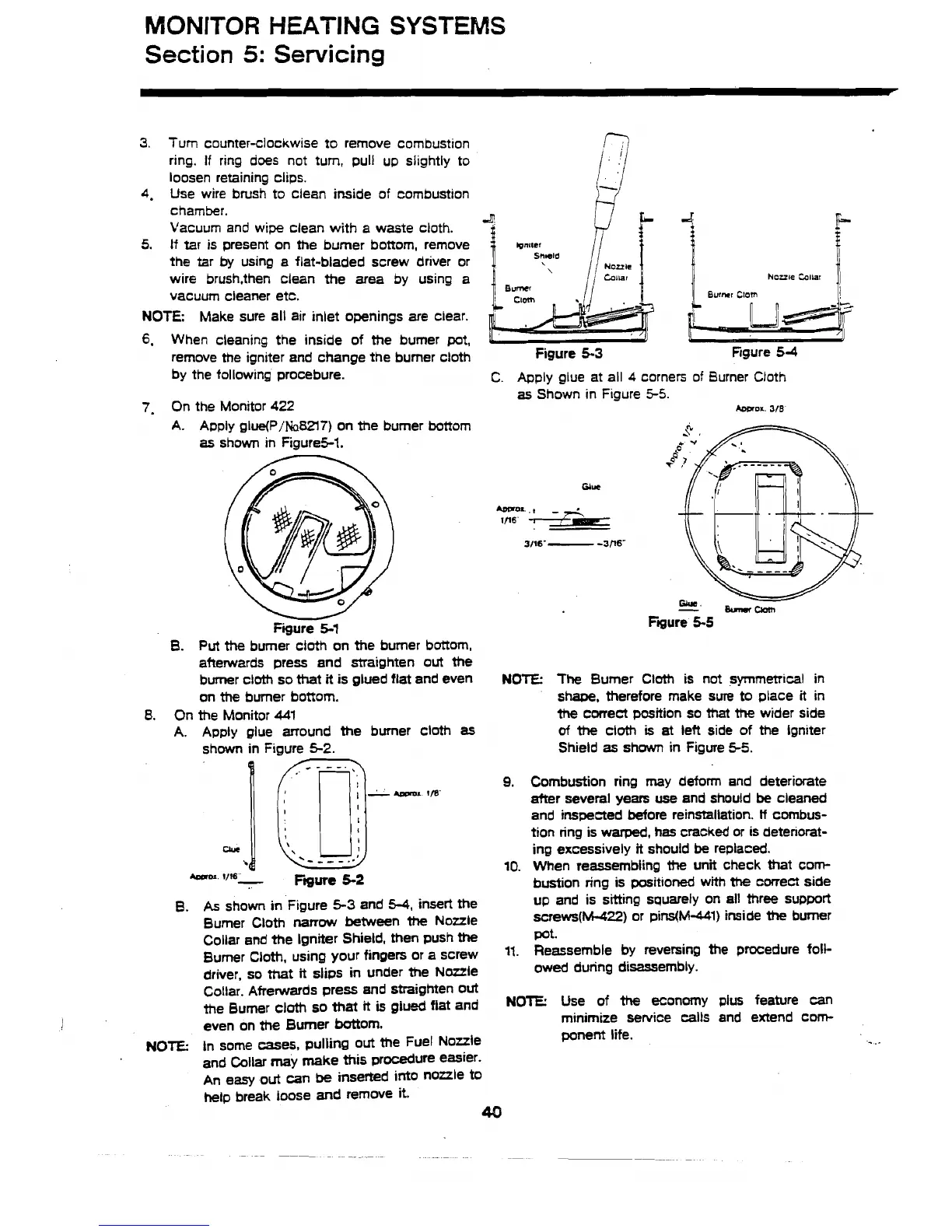

B.

As

shown in Figure

5-3

and

5-4,

insert the

Burner Cloth

narrow

between

the

Nozzle

Collar and the Igniter Shield, then push

the

Bumer Cloth, using your fingers or a screw

driver, so that

it

slips in under the Naule

1

Nozzle Collar

)I

Figure

5-3

Rgure

54

C.

Apply glue at all

4

corners of Burner Cloth

as

Shown in Figure

5-5.

Awroa.

318

NOTE:

The

Burner Cloth is not symmetrical in

shape, therefore make sure to place

it

in

the

correct position so that

the

wider side

of

the

cloth

is

at

lett side of the lgniter

Shield

as

shown in Figure

55.

9.

Combustion ring may deform and deteriorate

after several years

we

and should

be

cleaned

and inspected before reinstallation.

If

combus-

tion ring is

warped,

has cracked or is detenorat-

ing excessively

it

should

be

replaced.

10.

When reassembling

the

unit check that com-

bustion ring is positioned with

the

correct side

up and is sitting squarely on all three support

screws(~22) or pins(Ni-441) inside

the

bumer

Pot.

11. Reassemble by reversing the procedure foll-

owed during disassembly.

Collar.

Afrerwards press and straighten out

the Bumer cloth so that

it

is

glued fiat and

NOTE:

Use of

the

economy

plus

feature can

even on

the

Burner battom.

minimize service calls and extend corn-

NOTE:

in some mes, pulling out the Fuel Nozzle

ponent

life.

and Collar may make

this

procedure easier.

An

easy

out

can

be

inserted into nozzle

to

hetp break loose and remove

it.

40

Loading...

Loading...