4 If the engine has been run hard for a long period, let it idle for a few minutes

before switching off. This is sometimes known as

'Turbo

Run

Down'.

In all

engines, it will avoid the

risk

of

'After

Boil',

a condition where the cooling system

temperature continues to rise because of lack of circulation. Overheating can

cause excessive bearing wear in the

turbocharger.

Stern

gear_____________________________

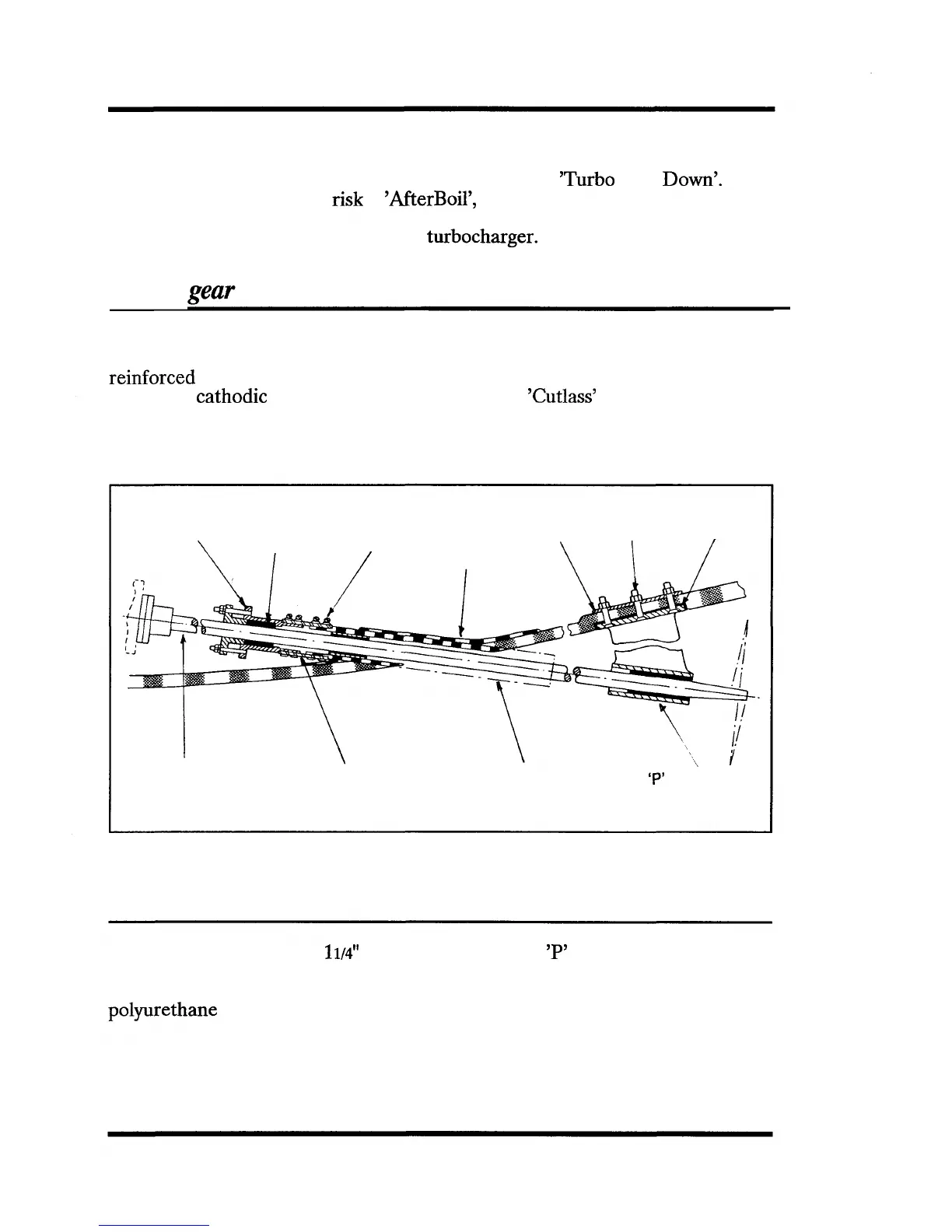

All yachts are fitted with a 'P' bracket type stern bearing. The strut is either pinned

through iroko hardwood blocks secured to the hull and glassed over, or bolted to a

reinforced

area to the hull. One securing bolt is electrically bonded to the sacrificial

anode for

cathodic

protection. A water lubricated

'Cutlass'

bearing supports the

stainless steel propeller shaft. The propeller shaft passes through a GRP stern tube

which is bonded to the hull. The tube is offset to enable the shaft to be withdrawn

without obstruction from the rudder.

Bronze fitting holding

gland packing Jubilee clips Backing plate Bolts

Gland packing /

CSM around tube

Rubboseal

Stainless steel shaft Reinforced rubber seal

housing gland bearing

and stern tude connections

GRP tube, gel coat seal

inside and out

'P'

Bracket with

Cutlass bearing

Typical stem gear installation

Cutlass bearing

All yachts use either 1" or

li/4"

cutlass bearings in the

'P'

bracket.

This type of water lubricated bearing is normally manufactured from neoprene or

polyurethane

and has a long life in clean water. High silt, sand and mud levels will

cause accelerated wear.

Page 4.8

Issue 3

Loading...

Loading...